Development and Experiments of Plasma High Temperature Oxygen-free Fuel Reformer

-

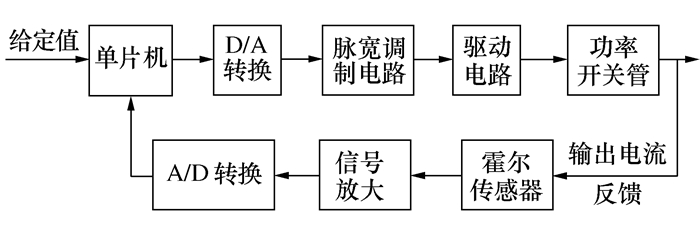

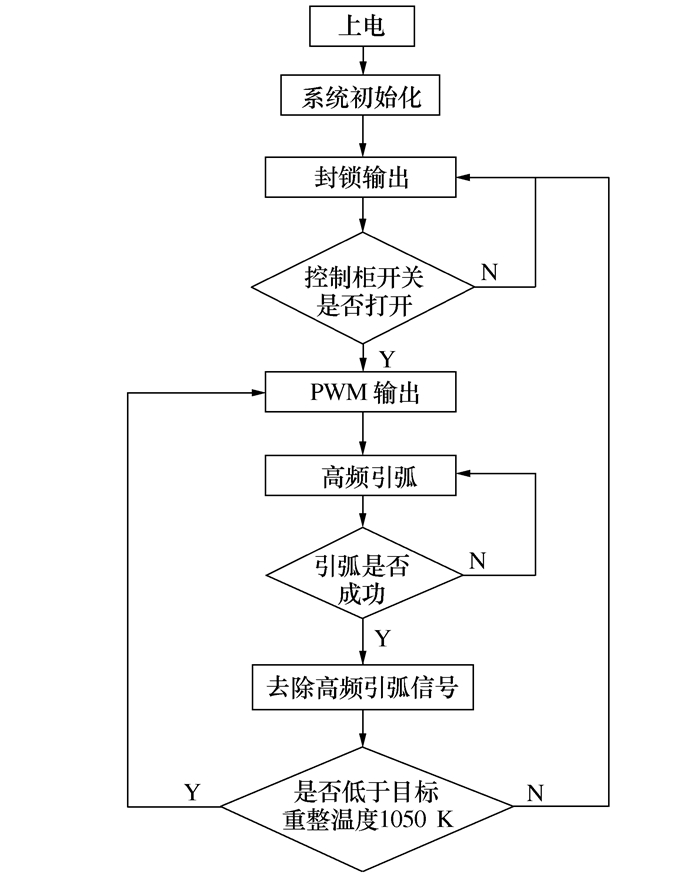

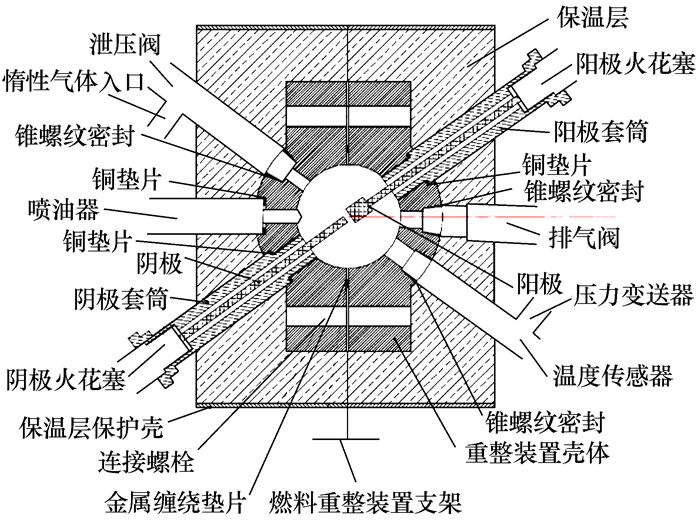

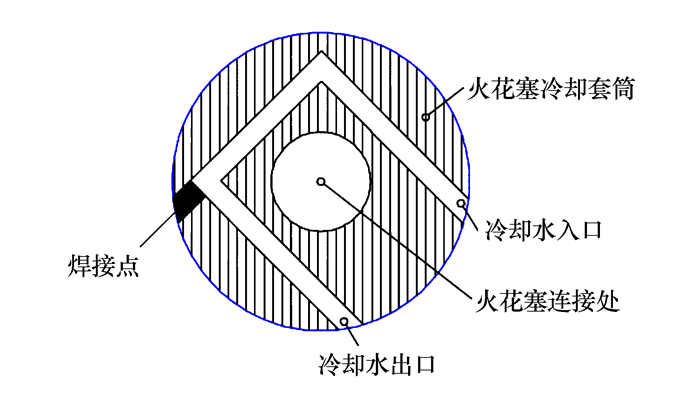

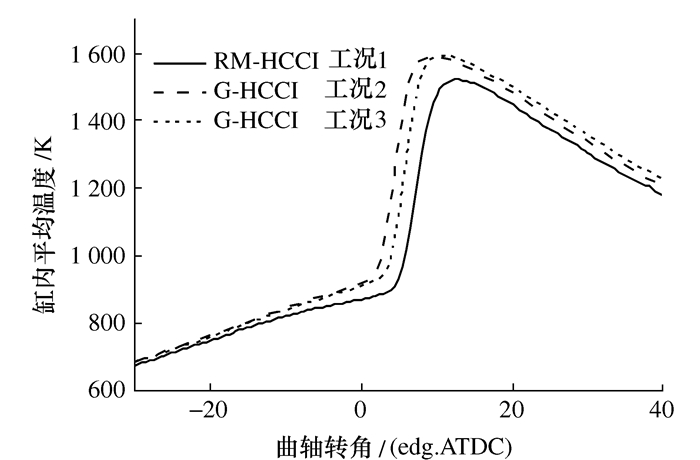

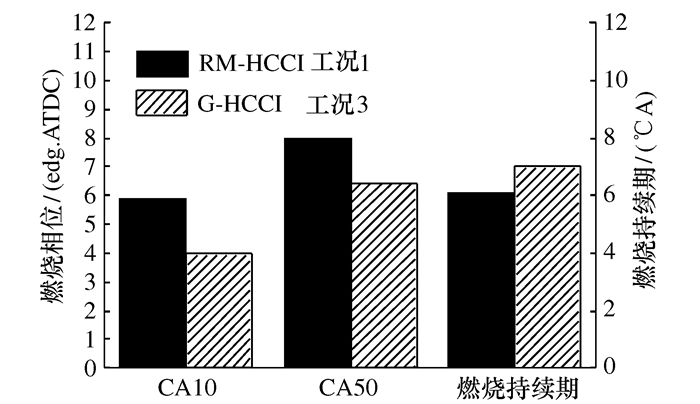

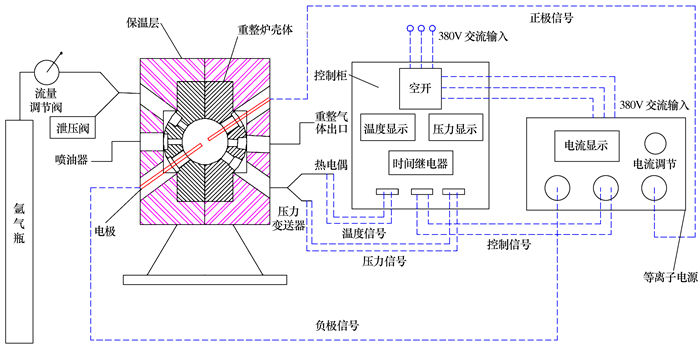

摘要: 设计开发了新型的高温无氧燃料重整装置及试验系统,该高温无氧重整利用发动机废气加热及等离子辅助加热的方式来实现,装置结构设计简单紧凑且无须催化剂的介入。等离子加热易于控制、传热面积小易于保温绝热,可减少能量损失。将正庚烷的重整产物引入发动机中成功实现了RM-HCCI(Reformed molecule homogeneous charge compression ignition,RM-HCCI)燃烧,将RM-HCCI和汽油均质压燃(Gasoline HCCI,G-HCCI)燃烧进行对比研究。研究表明,重整后的小分子燃料可延迟着火,传热损失率和排气损失率更低,可以获得更高的指示热效率。Abstract: A new high-temperature oxygen-free fuel reformer and testing system was designed and developed. The fuel reforming under high temperature and oxygen-free condition was realized by means of the engine exhaust gas heating and plasma heating assistance. The structure design of high temperature oxygen-free reformer was made simple and compact without catalyst. The plasma heating was easy to be controlled, small heat transfer area had easy insulation which could reduce energy loss. N-heptane was used as fuel to be reformed and Reformed molecule HCCI (RM-HCCI) combustion was successfully achieved by injecting the reformed fuel into the engine. The comparison between RM-HCCI and Gasoline HCCI (G-HCCI) combustion were carried out. The results showed that the reformed fuel delayed the ignition, resulting in lower heat transfer losses and exhaust losses, leading eventually to higher indicated thermal efficiency.

-

Key words:

- plasma /

- fuel reformer /

- design /

- experiments /

- HCCI combustion /

- indicated thermal efficiency

-

表 1 试验控制参数

参数名称 工况1 工况2 工况3 燃烧方式 RM-HCCI G-HCCI G-HCCI 进气压力/bar 1.8 1.8 1.8 进气温度/℃ 62 60 60 当量比 0.275 0.275 0.28 EGR/% 0 0 15 IMEPg/bar 7.5 7.4 7.5 指示热效率/% 53.56 51.23 51.19 RI/(MW·m-2) 3.8 5.6 4.4 Nox/ppm 6.50 7.00 7.00 -

[1] Dec J E, Yang Y. Boosted HCCI for high power without engine knock and with ultra-low NOx emissions-using conventional gasoline[J]. SAE International Journal of Engines, 2010, 3(1):750-767 doi: 10.4271/2010-01-1086 [2] 于文斌, 裴毅强, 苏万华.柴油机部分均质预混燃烧模式下混合与化学控制参数对指示热效率的影响[J].内燃机学报, 2012, 30(3):193-200 http://www.cnki.com.cn/Article/CJFDTOTAL-NRJX201203000.htmYu W B, Pei Y Q, Su W H. Effects of mixing and chemical parameters on thermal efficiency based on a partially premixed combustion diesel engine[J]. Transactions of CSICE, 2012, 30(3):193-200(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-NRJX201203000.htm [3] 尧命发, 刘海峰.均质压燃与低温燃烧的燃烧技术研究进展与展望[J].汽车工程学报, 2012, 2(2):79-90 doi: 10.3969/j.issn.2095-1469.2012.02.001Yao M F, Liu H F. Review and prospect of the combustion technology of homogeneous charge compression ignition and low temperature combustion[J]. Chinese Journal of Automotive Engineering, 2012, 2(2):79-90(in Chinese) doi: 10.3969/j.issn.2095-1469.2012.02.001 [4] Yao M F, Zhang B, Zheng Z Q, et al. Experimental study on homogeneous charge compression ignition combustion with primary reference fuel[J]. Combustion Science and Technology, 2007, 179(12):2539-2559 doi: 10.1080/00102200701486907 [5] Karatzas X, Nilsson M, Dawody J, et al. Characterization and optimization of an autothermal diesel and jet fuel reformer for 5 kW e, mobile fuel cell applications[J]. Chemical Engineering Journal, 2010, 156(2):366-379 doi: 10.1016/j.cej.2009.10.039 [6] Peters R, Dahl R, Klüttgen U, et al. Internal reforming of methane in solid oxide fuel cell systems[J]. Journal of Power Sources, 2002, 106(1-2):238-244 doi: 10.1016/S0378-7753(01)01039-4 [7] Shekhawat D, Berry D A, Haynes D J, et al. Fuel constituent effects on fuel reforming properties for fuel cell applications[J]. Fuel, 2009, 88(5):817-825 doi: 10.1016/j.fuel.2008.10.030 [8] Tsolakis A, Megaritis A. Catalytic exhaust gas fuel reforming for diesel engines-effects of water addition on hydrogen production and fuel conversion efficiency[J]. International Journal of Hydrogen Energy, 2004, 29(13):1409-1419 doi: 10.1016/j.ijhydene.2004.01.001 [9] Tsolakis A, Megaritis A. Exhaust gas assisted reforming of rapeseed methyl ester for reduced exhaust emissions of CI engines[J]. Biomass and Bioenergy, 2004, 27(5):493-505 doi: 10.1016/j.biombioe.2004.04.007 [10] 戴晓旭.基于尾气余热利用的掺混重整气汽油机性能的试验研究[D].北京: 北京工业大学, 2013 http://cdmd.cnki.com.cn/Article/CDMD-10005-1013046975.htmDai X X. Experimental study on performance of a hybrid syngas-gasoline engine based on waste heat recovery[D]. Beijing: Beijing University of Technology, 2013(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10005-1013046975.htm [11] Yuan F, Su W H. Numerical study on exergy losses of n-heptane constant-volume combustion by detailed chemical kinetics[J]. Energy & Fuels, 2014, 28(10):6635-6643 doi: 10.1021/ef5013374 [12] Yan F, Su W. A promising High efficiency RM-HCCI combustion proposed by Detail Kinetics Analysis of Exergy Losses[C]//SAE World Congress and Exhibition. Detroit: SAE International, 2015: 11 [13] Yu H, Su W. Numerical study on a high efficiency gasoline reformed molecule HCCI combustion using exergy analysis[C]//SAE World Congress Experience. Detroit: SAE International, 2017: 13 [14] 周龙保.内燃机学[M].2版.北京:机械工业出版社, 2005Zhou L B. Internal combustion engine[M]. 2nd ed. Beijing:China Machine Press, 2005(in Chinese) [15] 沈岩.低功率水电弧加热发动机的实验研究[D].北京: 清华大学, 2004 http://cdmd.cnki.com.cn/Article/CDMD-10003-2005036213.htmShen Y. Experimental research of low-power H2O arcjet[D]. Beijing: Tsinghua University, 2014(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10003-2005036213.htm [16] 刘威威.RM-HCCI燃烧的燃料重整研究[D].天津: 天津大学, 2014 http://cdmd.cnki.com.cn/Article/CDMD-10056-1016192028.htmLiu W W. Study on fuel reforming of RM-HCCI combustion[D]. Tianjin: Tianjin University, 2014(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10056-1016192028.htm [17] 董大勤, 袁凤隐.压力容器设计手册[M].北京:化学工业出版社, 2014Dong D Q, Yuan F Y. Pressure vessel design manual[M]. Beijing:Chemical Industry Press, 2014(in Chinese) [18] 闫峰.燃烧'火用'损失机理及重整燃料分子均质压燃燃烧研究[D].天津: 天津大学, 2016 http://cdmd.cnki.com.cn/Article/CDMD-10056-1017134262.htmYan F. Numerical study on exergy losses of combustion process by detailed chemical kinetics and on the promising high efficiency RM-HCCI combustion principle[D]. Tianjin: Tianjin University, 2016(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10056-1017134262.htm -

下载:

下载: