Study on Numerical Simulation of Double Droplets Infiltration in 3DP Technology

-

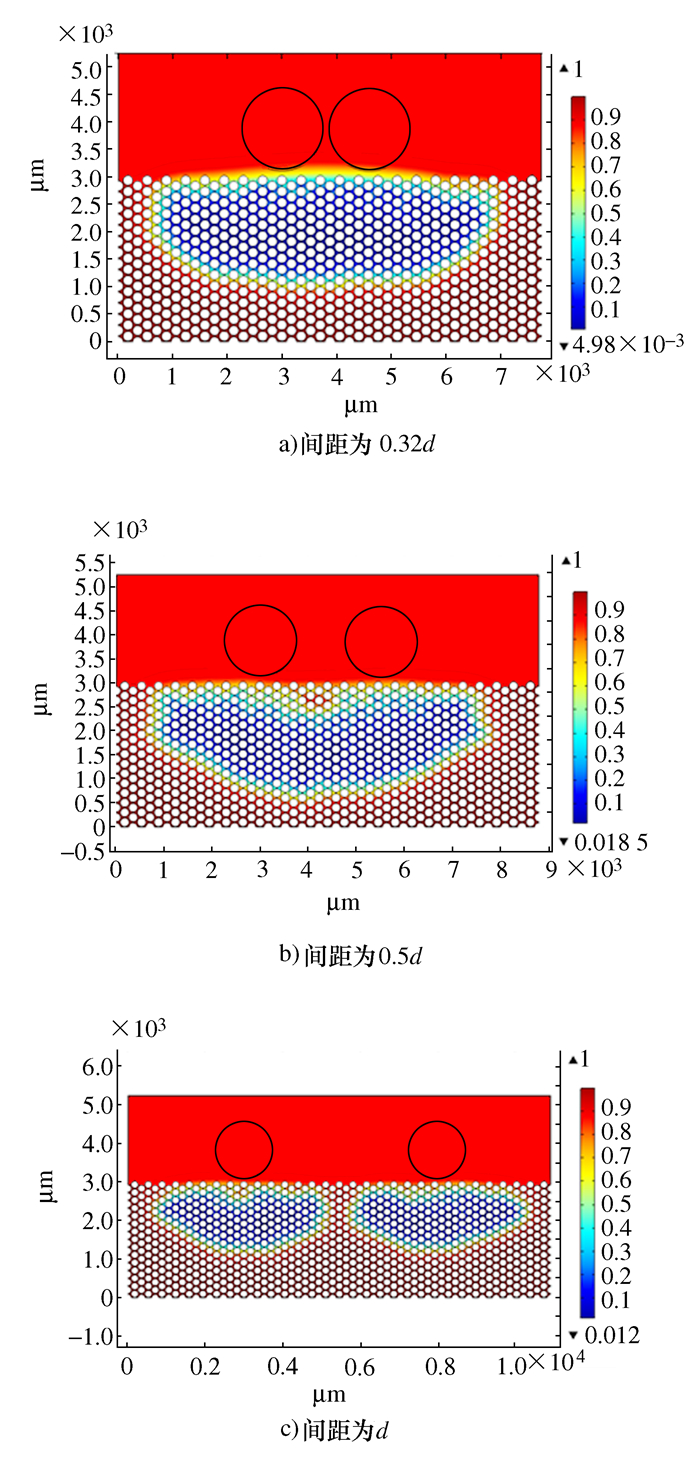

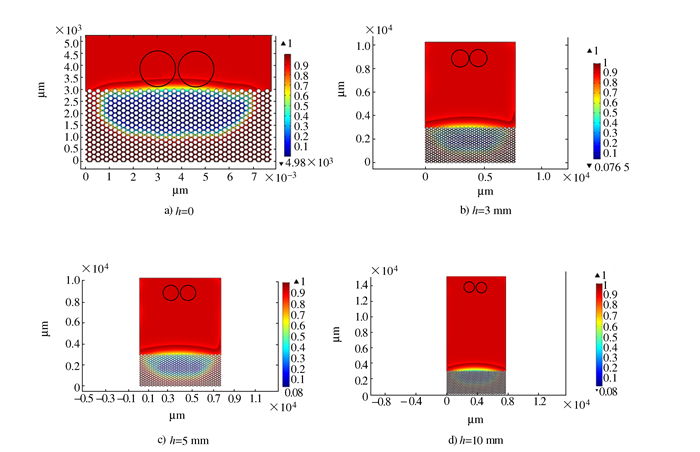

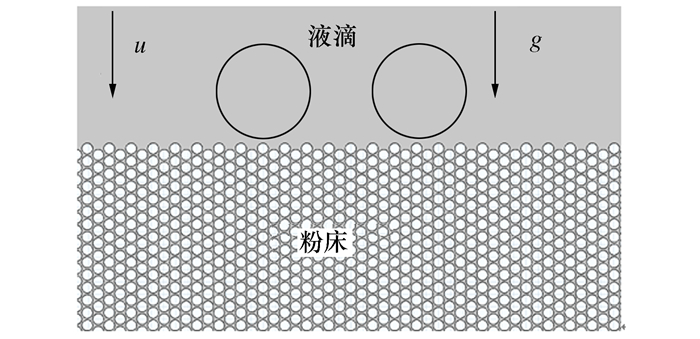

摘要: 为了提高3DP工艺的精度,需预测粘结剂与颗粒材料粘结的形态,而通过实验很难观测到液滴在粉床中的渗透过程。本文通过应用水平集方法建立了双液滴渗透过程的数学模型,运用多物理场仿真软件COMSOL对其进行了数值模拟,分析了主要工艺参数-液滴水平间距和滴落高度对液滴渗透的形态的影响。同时为验证数学模型和仿真结果的一致性,搭建了实验平台,采用高速摄影对液滴的滴落渗透过程进行图像采集,并通过电子显微镜观测最终的凝聚形态。将实验结果与仿真结果进行了对比,验证了数值模拟的准确性,为进一步的实验研究提供了理论依据。Abstract: It is difficult to observe the infiltration process of droplets in the powder bed through experiments, therefore a mathematical model is established with the horizontal set method, in order to improve the accuracy of three-dimension printing(3DP) process and to predict the bonding of binder and granular material. The numerical simulation of droplets infiltration process is carried out via COMSOL software. The forms of droplets infiltration are influenced mainly by the droplets horizontal spacing and drop height. The experiment platform is set up to verify the consistency of the mathematical model and simulation results. The high-speed camera is utilized to capture the images of droplets infiltration process and the electron microscopy is utilized to observe the final condensed forms. The experimental results are compared with the simulated, in which the accuracy is verified, and which provides a basis for further research.

-

Key words:

- 3DP technology /

- numerical simulation /

- COMSOL /

- droplets infiltration

-

表 1 呋喃树脂溶液参数表

参数 密度/(kg·m-3) 动力粘度/(Pa·s) 表面张力/(N·m-1) 接触角/(°) 数值 1.120×103 9.75×10-3 4.29×10-2 31.72 -

[1] Wei Q H, Wang Y N, Chai W H, et al. Molecular dynamics simulation and experimental study of the bonding properties of polymer binders in 3D powder printed hydroxyapatite bioceramic bone scaffolds[J]. Ceramics International, 2017, 43(16):13702-13709 doi: 10.1016/j.ceramint.2017.07.082 [2] Zhou Z X, Cunningham E, Lennon A, et al. Effects of poly (ε-caprolactone) coating on the properties of three-dimensional printed porous structures[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 70:68-83 doi: 10.1016/j.jmbbm.2016.04.035 [3] Sun C N, Tian X Y, Wang L, et al. Effect of particle size gradation on the performance of glass-ceramic 3D printing process[J]. Ceramics International, 2017, 43(1):578-584 doi: 10.1016/j.ceramint.2016.09.197 [4] 杨伟东, 贾鹏飞, 马媛媛, 等.3D打印工艺中粘结剂渗透建模与仿真[J].纳米技术与精密工程, 2017, 15(4):246-253 http://d.old.wanfangdata.com.cn/Periodical/nmjsyjmgc201704002Yang W D, Jia P F, Ma Y Y, et al. Modeling and simulation of binder droplet infiltration in 3D printing technology[J]. Nanotechnology and Precision Engineering, 2017, 15(4):246-253(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/nmjsyjmgc201704002 [5] Vaidya R, Anand S. Image processing assisted tools for pre-and post-processing operations in additive manufacturing[J]. Procedia Manufacturing, 2016, 5:958-973 doi: 10.1016/j.promfg.2016.08.084 [6] Asadi-Eydivand M, Solati-Hashjin M, Farzad A, et al. Effect of technical parameters on porous structure and strength of 3D printed calcium sulfate prototypes[J]. Robotics and Computer-Integrated Manufacturing, 2016, 37:57-67 doi: 10.1016/j.rcim.2015.06.005 [7] Shakor P, Sanjayan J, Nazari A, et al. Modified 3D printed powder to cement-based material and mechanical properties of cement scaffold used in 3D printing[J]. Construction and Building Materials, 2017, 138:398-409 doi: 10.1016/j.conbuildmat.2017.02.037 [8] Olsson E, Kreiss G. A conservative level set method for two phase flow[J]. Journal of Computational Physics, 2005, 210(1):225-246 doi: 10.1016/j.jcp.2005.04.007 [9] Olsson E, Kreiss G, Zahedi S. A conservative level set method for two phase flow Ⅱ[J]. Journal of Computational Physics, 2007, 225(1):785-807 doi: 10.1016/j.jcp.2006.12.027 [10] 戴剑锋, 樊学萍, 蒙波, 等.单液滴撞击倾斜液膜飞溅过程的耦合Level Set-VOF模拟[J].物理学报, 2015, 64:094704 http://d.old.wanfangdata.com.cn/Periodical/wlxb201509032Dai J F, Fan X P, Meng B, et al. A coupled level-set and volume-of-fluid simulation for splashing of single droplet impact on an inclined liquid film[J]. Acta Physica Sinica, 2015, 64:094704(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/wlxb201509032 [11] Shepel S V, Smith B L. New finite-element/finite-volume level set formulation for modelling two-phase incompressible flows[J]. Journal of Computational Physics, 2006, 218(2):479-494 doi: 10.1016/j.jcp.2006.02.008 [12] 房巨强.三维打印快速成形机理及其加工质量控制技术研究[D].沈阳: 东北大学, 2010 http://cdmd.cnki.com.cn/Article/CDMD-10145-1013116133.htmFang J Q. Study on three-dimensional printing mechanism and control measures of prototype quality[D]. Shenyang: Northeastern University, 2010(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10145-1013116133.htm [13] 钟小彦.基于多孔介质模型和VOF法的渗流场数值模拟[D].西安: 西安理工大学, 2010 http://cdmd.cnki.com.cn/Article/CDMD-10700-2010140818.htmZhong X Y. Numerical simulation of seepage field based on porous media model and VOF method[D]. Xi'an: Xi'an University of Technology, 2010(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10700-2010140818.htm [14] Kumar S M, Deshpande A P. Dynamics of drop spreading on fibrous porous media[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2006, 277(1-3):157-163 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=55dbc3ea00b45f1bde23fadf959599ff [15] Lunkad S F, Buwa V V, Nigam K D P. Numerical simulations of drop impact and spreading on horizontal and inclined surfaces[J]. Chemical Engineering Science, 2007, 62(24):7214-7224 doi: 10.1016/j.ces.2007.07.036 [16] 刘栋.液滴碰撞及其融合过程的数值模拟研究[D].北京: 清华大学, 2013 http://cdmd.cnki.com.cn/article/cdmd-10003-1014020572.htmLiu D. Numerical simulations on collision and coalescence of binary droplets[D]. Beijing: Tsinghua University, 2013(in Chinese) http://cdmd.cnki.com.cn/article/cdmd-10003-1014020572.htm -

下载:

下载: