2. 西北工业大学深圳研究院, 深圳 518057

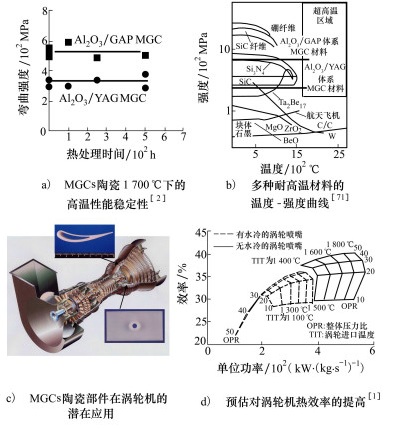

超高温氧化物共晶陶瓷具有优异的耐高温、抗氧化、抗腐蚀、抗蠕变和高温强度等特性,特别相较于传统烧结陶瓷,具有杰出的高温力学性能和高温结构稳定性,以及极端高温水氧腐蚀环境下优异的抗氧化腐蚀性能[1]。此外,熔体生长的氧化物共晶陶瓷经机械加工后,能够用于无需冷却的涡轮发动机喷嘴、导向叶片及燃烧室内衬,预计将提高发动机热效率达9%[1],并大大降低氮氧化物等废气的排放。因此,熔体生长的氧化物共晶陶瓷在航空航天领域具有极大的工程应用前景及潜在的经济价值,有望成为1 600 ℃以上超高温氧化性气氛中长期服役的新一代先进结构材料。

定向凝固是制备氧化物共晶陶瓷的核心关键技术[2]。传统定向凝固技术,如布里奇曼法(Bridgman, BM)、边界外延生长法(edge defined film fed growth, EFG)、微抽拉法(micro pulling down, MPD)等适合制备表面光滑、高致密度的棒状氧化铝基共晶陶瓷。然而,受坩埚形状、尺寸及材料特性等限制,所制样品形状简单、尺寸较小,凝固组织粗大,限制了力学性能的提高和工程应用,难以满足复杂化、均细化、强韧化超高温氧化物陶瓷的迫切需求。因此,亟需开发新的凝固制备技术及综合利用各种调控手段,全面提升氧化铝基共晶陶瓷的成形质量及综合力学性能。近年来发展的高梯度定向凝固技术,例如激光悬浮区熔法(laser floating zone melting, LFZM)、激光区熔法(laser zone melting, LZM)、激光加热基座生长法(laser heated pedestal growth, LHPG)、选区激光熔化(selective laser melting, SLM)、激光增材制造(laser additive manufacture, LAM)等方法在获得高致密、组织细小、柔性制造成形等方面具有突出的优势[3]。然而,陶瓷具有较高的脆硬特性,在高梯度定向凝固过程中,易产生多种加工缺陷,成为高性能、复杂结构、超高温氧化铝基共晶陶瓷的制备难点。

本文综述了超高温氧化铝基共晶陶瓷定向凝固技术的发展现状,探讨了氧化物共晶陶瓷高梯度定向凝固过程中气孔、裂纹等缺陷的产生机理及控制方法,概述了凝固组织特征、均细化调控方法及晶体取向研究现状,总结了氧化物共晶陶瓷的力学性能及强韧化调控方法。最后,展望了高梯度定向凝固制备高性能大尺寸氧化物共晶陶瓷的发展趋势。

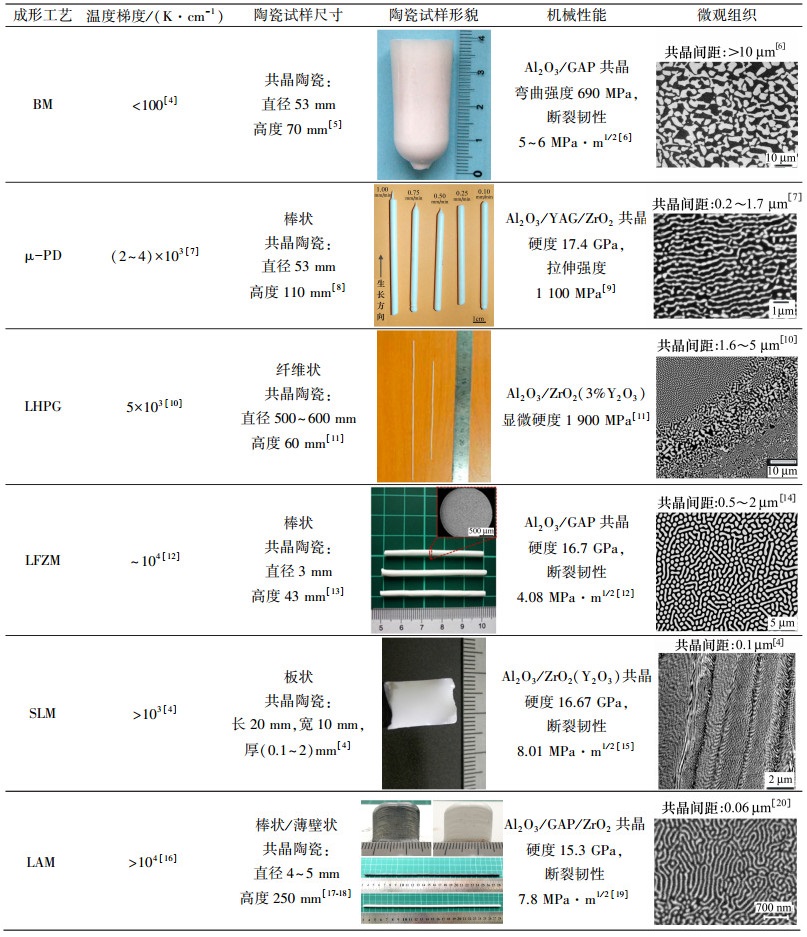

1 氧化铝基共晶陶瓷高梯度定向凝固技术及缺陷控制 1.1 氧化物共晶陶瓷凝固成形技术目前,发展的氧化铝基自生复合共晶陶瓷制备技术的原理特征及所制陶瓷试样的宏观形貌、力学性能和凝固组织如表 1所示。

从表 1可知,共晶陶瓷凝固技术的发展历史是温度梯度不断提升、凝固组织不断细化的过程。BM法已能够制备出较大尺寸共晶陶瓷[5],但该技术温度梯度小(< 100 K/cm),凝固速率低(5 mm/h[21]),晶体生长周期长,共晶组织粗大,且坩埚成本高,易与共晶陶瓷反应,造成污染和性能恶化。μ-PD法和LHPG法适合制备直径为毫米级或更细小的纤维/细棒状共晶陶瓷,对加工材料具有较广泛的适用性,通过调节抽拉速率可以实现微观组织调控,但该技术较难实现大尺寸和复杂形状试样的制备。LFZM法采用高能激光束作为热源,具有较高的温度梯度,能够制备出组织致密且无明显气孔和裂纹缺陷的共晶陶瓷,试样形状为棒状,且直径普遍小于5 mm[12]。近年来,陶瓷LAM技术取得了长足进展,已成功获得了表面光滑且高致密(98.7%)的不同形状的棒状及薄壁状Al2O3/GAP/ZrO2三元共晶陶瓷[22],尺寸可分别达到Φ(4~5)mm×h250 mm[18], 约15 mm×13 mm×4 mm[17],且具有良好的热稳定性。

1.2 氧化物陶瓷凝固缺陷形成及其控制氧化铝基共晶陶瓷具有高的熔点(Al2O3/YAG共晶陶瓷熔点1 826 ℃)[23]、高的熔体黏度(Al2O3熔体黏度高达30 m·Pa·s[24],金属铝的熔体黏度仅为1.2~4.2 m·Pa·s[25])、复杂的成分和化合物相组成,以及高脆硬特性,使其在定向凝固过程,特别是在高温度梯度、高凝固速率下极易出现气孔、裂纹、缩松以及杂晶等凝固缺陷,严重影响共晶陶瓷的成形质量与力学性能。

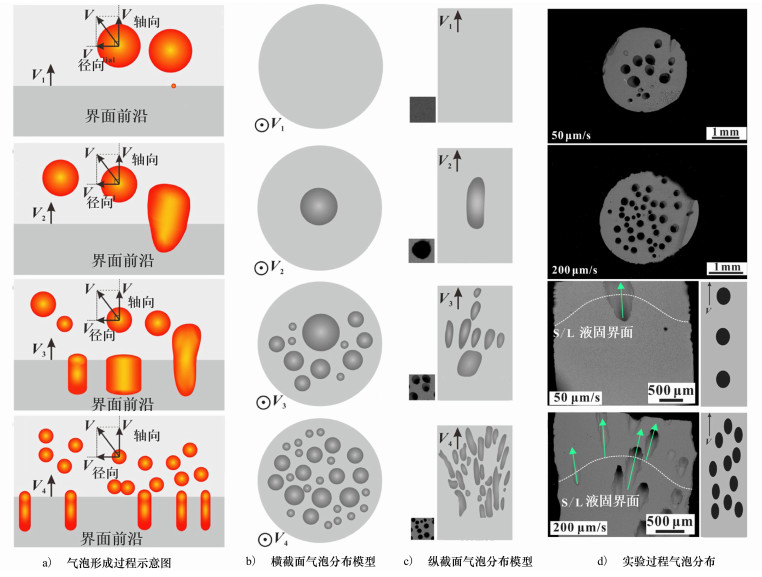

苏海军等[26]建立了氧化铝基共晶陶瓷LFZM制备过程中的气孔形核、长大、粗化模型,如图 1所示。研究发现,凝固速率小于25 μm/s时,Al2O3/EAG/ZrO2凝固陶瓷几乎没有气孔,凝固速率提高至25 μm/s时,试样中心产生了尺寸约为Φ300 μm的气孔。随凝固速率增大,气孔尺寸增大,数量增多。根据表面张力梯度及气泡临界迁移速率进一步分析,气泡由固液界面前沿非均质形核产生。

|

| 图 1 不同凝固速率下气孔分布 |

LAM技术[27]具有较高温度梯度(>104 K/cm)、扫描速率(300~1 000 mm/min)和冷却速率(103~104 K/s)[16]。激光作用下,熔池中气体溶解度、凝固速率和气泡长大/迁移速率的综合作用导致气孔尺寸和分布随加工参数的变化呈现不同特征[26]。Yan等[28]发现激光加工过程中由于骤冷造成试样顶部缩孔缺陷。熔池中气体的逸出速度低于凝固速度,被凝固界面捕获[29],易形成规则球形气孔,液相补缩不足形成缩孔。随激光功率增大,气孔率先增大后减小;随扫描速率增大,气孔率先减小后增大;随送粉气流增大,气孔率持续增大。李发智等[30]基于凝固理论及气泡动力学,建立了气孔形成判据。研究发现,熔池中心部位气孔率较大,边缘部位气孔率低,多为单一圆形气孔。随激光功率增大,马兰戈尼对流增强,气孔率降低。

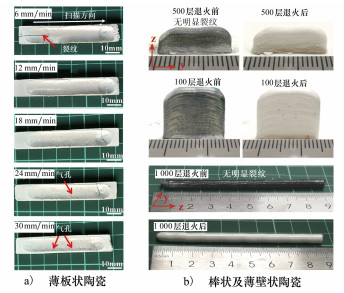

激光快速凝固过程中,易产生较大的残余应力,且不断积累,促使裂纹萌生并扩展。刘海方等[31]利用LAM技术制备Al2O3/GAP/ZrO2共晶陶瓷过程中发现,增大激光功率或降低扫描速率均会增大骤冷应力,从而产生裂纹缺陷。当扫描速率增大至12 mm/min时,获得了表面光滑无裂纹的薄板共晶陶瓷,如图 2a)所示。进一步,通过1 000 ℃预热及加工结束后逐级降低激光功率往复扫描,能够降低冷却速率,减小热应力,成功获得了无明显裂纹缺陷的氧化物共晶陶瓷[17],如图 2b)所示。

|

| 图 2 LAM制备的Al2O3/GAP/ZrO2共晶陶瓷 |

吴东江等[32]研究发现,LAM制备Al2O3陶瓷过程中,添加ZrO2和Y2O3能够实现晶粒细化,有效减少裂纹缺陷。Al2O3/ZrO2共晶陶瓷的LAM制备过程中,添加不同含量(质量分数10%~25%)和尺寸(45~90 μm)的SiC粉末能够明显减少裂纹数量。SiC颗粒周围发生界面反应,能够实现与基体的紧密结合。此外,由断裂表面能、弹性模量和膨胀系数不匹配产生的能量耗散机制,能够有效抑制裂纹扩展。Ferrage等[33]在氧化钇稳定氧化锆粉末(YSZ)中加入少量石墨(体积分数 < 5%),使Nd∶YAG激光的吸收率由2%提高至50%~60%,明显减少了裂纹缺陷。此外,通过工艺调控[34-35]包括控制粉末特性, 调节激光功率、扫描速率等工艺参数, 引入基板预热、超声振动、水冷辅助等[36-38]方法,均可实现裂纹缺陷的抑制。

2 氧化铝基共晶陶瓷凝固组织特征及均细化调控 2.1 高梯度定向凝固组织特征苏海军等[26]研究发现,LFZM技术高温度梯度(约104 K/cm)和凝固速率下(约400 μm/s),共晶陶瓷共晶间距为0.193 μm[39],组织形貌随工艺参数不断变化。苏海军和马为丹等[40-41]利用LFZM法制备Al2O3/GAP/ZrO2共晶陶瓷过程中发现,随凝固速率的增大,组织由象形文字非规则共晶形貌向棒状和层片状规则共晶形貌转变,如图 3a)~3d)所示。当远离Al2O3/GAP共晶成分时,易生成初生相:AG15亚共晶中,树枝状Al2O3初生相领先生长(见图 3e)),AG28过共晶中,GAP树枝状初生相优先生长(见图 3f))[42]。

|

| 图 3 LFZM制备的氧化物陶瓷凝固组织形貌 |

另外,马为丹等[43]发现,由于LFZM过程中熔区的不稳定性,在低抽拉速率下易出现表面周期性起伏形貌,凝固速率V和周期性条带长度L符合L/V≈(275.6±2.1) s,微观组织呈现周期性带状形貌。苏海军等[40]研究发现,LFZM过程中温度梯度周期性变化,单相组织不稳定性和初生相在固液界面前的自由生长导致了微观组织周期性生长条纹的形成,随扫描速率的增加(>25 μm/s),组织不稳定性减弱。

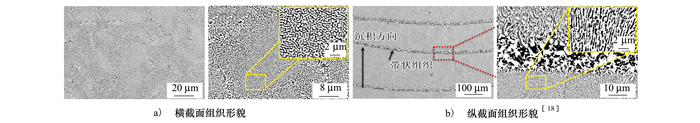

刘海方等[18]在LAM打印Al2O3/GAP/ZrO2共晶陶瓷过程中发现,试样出现周期性组织粗化区,且该区域的组织尺寸是其他区域的4~5倍,很大程度上影响了试样的组织均匀性,可能成为试样的性能弱化区[17]。Yan等[44]研究了组织粗化区的成因:不平稳固液界面导致温度梯度差异大,引起热流扰动,造成固液界面前沿成分过冷及单相失稳,从而形成了粗大带状组织。刘海方等[17]研究表明,沉积层部分重熔时,紧邻熔池区域的细小组织受到接近熔点的高温作用而发生快速粗化,从而形成了周期性带状组织粗大区[17-18],如图 4所示。

2.2 凝固组织均细化调控高温度梯度定向凝固过程中,易产生固液界面失稳,加上氧化物陶瓷小平面相凝固特性的影响,氧化物共晶陶瓷凝固组织呈现多样性、不均匀性。粗大初生相及组织粗化区极易减小韦伯系数[43],削弱材料力学性能。因此任群等[45]以MK模型及最高界面生长温度假设为基础,研究了LFZM制备Al2O3/EAG共晶过程中各相的竞争生长,计算获得了初生相与共晶相的共生生长区间。研究表明,低速下近共晶成分亦可获得完全共晶组织,避免了树枝晶和初生相的生成(二元体系共生生长范围为摩尔分数15.5%~22.5%Er2O3)。

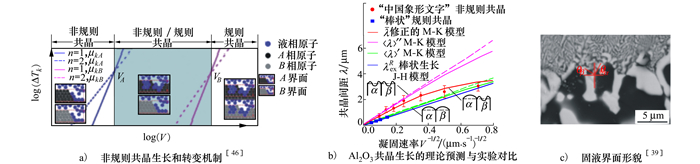

任群等[46]建立了原子团簇物理模型,如图 5a)所示。研究发现,小平面相体积分数和凝固速率共同影响共晶体系的组织规则化进程,其中凝固速率起主导作用。马为丹等[39, 42]综合利用规则共晶的JH模型及非规则共晶的GK模型,定量表征了Al2O3/GAP共晶的凝固速率与共晶间距的关系(见图 5b)),为凝固组织均细化调控提供了理论依据。

|

| 图 5 氧化铝基共晶自生复合陶瓷规则非规则共晶生长和转变机制 |

Yan等[44]通过调整工艺参数将带状组织粗大区的厚度减小至约10 μm,但效果有限。吴东江等[47]采用LAM技术在钛合金和Al2O3/YAG复合陶瓷基板上制备氧化铝陶瓷,由于钛合金基板导热系数高,冷却速率大,从而促进陶瓷晶粒细化。吴东江等[20, 48]研究了普通基板和水冷恒温基板对LAM制备Al2O3/YAG共晶陶瓷组织和性能的影响。结果表明,在水冷恒温基板上制备的Al2O3/YAG共晶陶瓷共晶间距减小了78%(210 μm),硬度提升了10%。

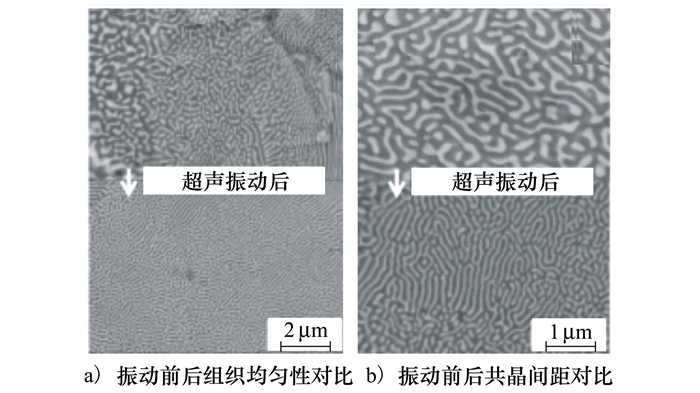

2018年,Hu等[37]将超声振动引入LAM中,通过超声破碎和深过冷形核的方式实现组织的超细化和均匀化,如图 6所示。Yan等[49-50]采用超声辅助的LAM成功制备出具有纳米组织(共晶间距60~70 nm)的Al2O3/ZrO2共晶陶瓷,揭示出超声后临界形核半径和自由能的降低是导致层片间距减小的主要原因。

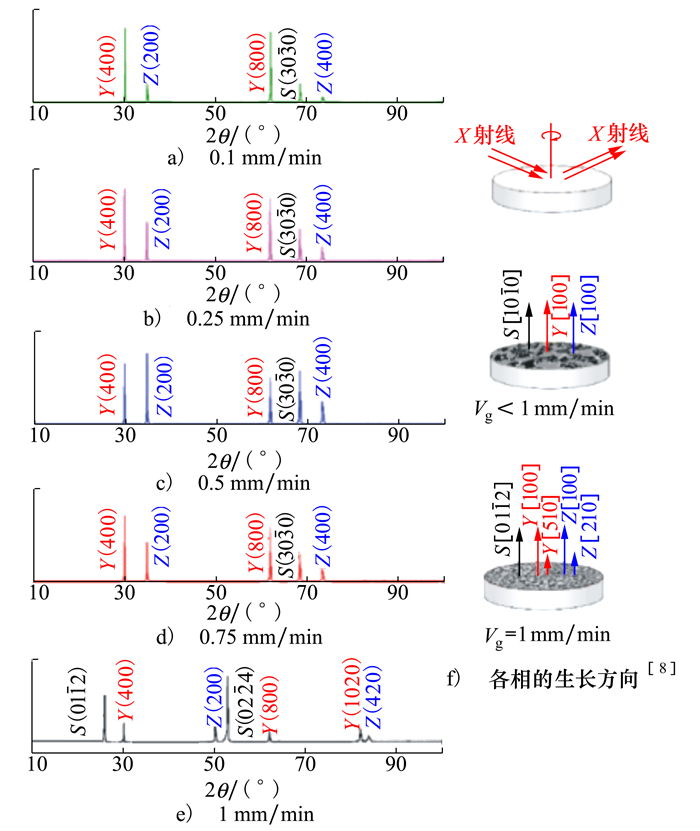

3 氧化铝基共晶陶瓷晶体取向选择与织构控制研究 3.1 氧化铝基共晶陶瓷的晶体学取向关系熔体生长技术使氧化铝基共晶陶瓷各相在特定热流驱动下择优生长,共晶相之间基于最小界面能原则形成了一定的晶体学取向以及相界面关系,如表 2所示。Benamara等[8]采用μ-PD法考察了凝固速率对Al2O3/YAG/ZrO2三元共晶陶瓷晶体学取向的影响,如图 7所示。

|

| 图 7 不同提拉速率(Vg)下,块状Al2O3/YAG/ZrO2共晶陶瓷横截面XRD图 |

| 共晶体系 | 制备方法 | V/(mm·h-1) | 晶体学取向关系 |

| Al2O3/YAG | BM[21] | 5 | 〈110〉Al2O3//〈743〉YAG |

| OFZ[51] | 10 | [0001]Al2O3//[112]YAG [1100]Al2O3//[111]YAG |

|

| LFZ[52] | 111.1 | (012-3)Al2O3//(444)YAG | |

| BM[53] | 10 | [1010]Al2O3//[101]YAG | |

| LAM[54] | 5.08 | 〈101-0〉Al2O3//〈111〉YAG | |

| Al2O3/ZrO2 | LZM[55] | 36, 72 | (1-102-)Al2O3//(1-10)ZrO2 [0221]Al2O3//[111]ZrO2 |

| μ-PD[56] | 54 | (112-0)Al2O3//(100)GAP [0001]Al2O3//[010]GAP |

|

| Al2O3/GAP | OFZ[57] | 2~20 | (112-0)Al2O3//(001)GAP [1100]Al2O3//[110]GAP |

| BM[6] | 5 | [1014]Al2O3//[111]GAP | |

| Al2O3/EAG/ZrO2 | LFZM[58] | 1 200 | [0001]Al2O3//[100]ESZ (101-0)Al2O3//(010)ESZ |

| Al2O3/YAG/ZrO2 | OFZ[59] | 10 | 〈11-00〉Al2O3//〈001〉YAG//〈001〉ZrO2 {112-0}Al2O3//{001}YAG//{001}ZrO2 |

低凝固速率下(< 0.75 mm/min)存在[100]YAG//[100]ZrO2//[1010]Al2O3的晶体学取向关系。凝固速率提高至1 mm/min时,单晶取向逐渐转变为多重晶体学取向,并伴随择优生长方向的转变。表 2中的研究同样证实了氧化物共晶晶体学择优取向随凝固工艺的变化呈现出多重取向关系。

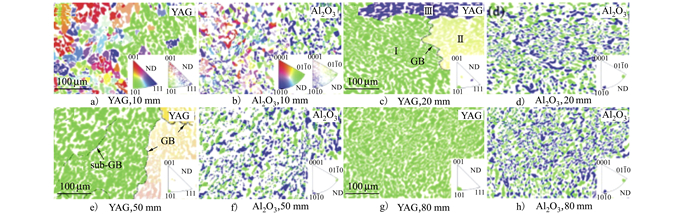

为明确氧化铝基共晶陶瓷在凝固过程中晶体学取向的演变规律,王旭等[51]采用光学浮区法(optical floating zone, OFZ)以10 mm/h的凝固速率制备了单晶相Al2O3/YAG二元共晶复合陶瓷。研究发现,凝固初期Al2O3和YAG两相均处于晶体学取向竞争阶段,如图 8所示。

随着定向凝固过程的进行,两相以稳定单晶([1010]Al2O3//[101]YAG)取向实现互适配来满足相界面能最小原则[60]。在此取向关系下,Al2O3和YAG两相之间形成了低界面能半共格界面,界面上仅存在-0.57%的错配。Fan等[54]在LAM制备过程中发现了由随机取向趋于稳定织构(〈101-0〉Al2O3//〈111〉YAG)的现象。往复扫描、层层堆积、快速熔凝的工艺特征,造成了YAG相的择优取向并不一致。

3.2 氧化铝基共晶陶瓷织构调控Waku等[6, 21]发现定向凝固氧化铝基共晶自生复合陶瓷各向异性明显,尤其在择优生长方向上表现出更加优异的室温和高温力学性能。定向凝固晶体生长过程中,使用籽晶可以对凝固过程中晶体学取向演变及织构调控产生影响,进而提升材料力学性能。Murayama等[61]分别采用μ-PD法和BM法,通过控制凝固参数,制备了c轴和a轴Al2O3引晶的Al2O3/YAG/ZrO2三元共晶陶瓷,研究了Al2O3相的生长取向对高温强度的影响。Al2O3相继承了籽晶的晶体学取向,YAG并未实现晶体学取向的稳定调控。此外,1 600 ℃下的高温强度与Al2O3相的晶体学取向强烈相关,且在c轴[0001]Al2O3取向上获得最高的压缩强度(600 MPa)。

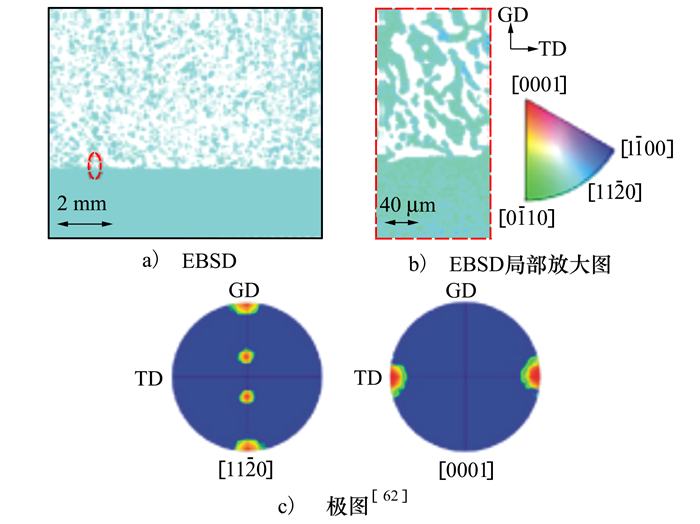

Yoshimura等[62]以a轴Al2O3单晶为籽晶,采用BM法制备了Al2O3/YAG: Ce共晶,并在初始连接部位观察到共晶中Al2O3相继承了籽晶的晶体学取向(见图 9)。王旭等[63]以c轴Al2O3单晶为籽晶,采用OFZ法制备了Al2O3/YAG共晶,发现Al2O3相同样继承了籽晶的取向,利用近重位点阵模型揭示了相界面能在定向凝固过程中起主导作用。

|

| 图 9 Al2O3相沿生长方向的EBSD图和极图 |

氧化铝基共晶陶瓷以其独特的三维缠绕共晶结构及高熔点、低密度、抗氧化、良好的高温力学性能、优异的组织和性能热稳定性等特点,受到国内外学者的广泛关注。1997年,日本Waku等[6]报道了BM法制备的Al2O3/YAG共晶具有优良的力学性能:抗弯强度从室温至1 800 ℃(共晶点温度1 826 ℃)始终保持在350~400 MPa,如图 10所示。1 600 ℃和10-4/s应变速率下,压缩蠕变强度高达433 MPa,是同成分烧结陶瓷的7~13倍;1 700 ℃抗拉强度160 MPa。1 600 ℃下Al2O3/YAG/ZrO2三元共晶的弯曲强度高达851 MPa,为同成分烧结陶瓷的57倍[64]。日本Lee等[9, 65-66]采用μ-PD法,900 mm/h速率下成功制备出Al2O3/YAG/ZrO2陶瓷纤维,1 200 ℃下的拉伸强度为970 MPa(室温下为1 100 MPa),1 500 ℃下生长方向上的压缩强度高达1 400 MPa,并伴随塑性变形。

|

| 图 10 氧化物陶瓷高温性能及应用前景 |

Pastor等[67]研究发现,棒状Al2O3/YAG共晶陶瓷(Φ1 mm)的抗弯强度与凝固速度成正比,750 mm/h速率下室温强度为2 GPa,1 627 ℃下受组织粗化影响略微下降,但强度仍高达1.53 GPa。Oliete等[68]制备的Al2O3/YAG/YSZ纳米共晶纤维弯曲强度高达4.6 GPa。Oliete等[68]研究表明,弯曲强度与材料组织尺寸成反比,均细化微观组织有利于提高氧化物共晶陶瓷性能。Park等[69]采用EFG法制备出Φ75 μm纤维状Al2O3/YAG共晶陶瓷,拉伸强度达到1.37 GPa。美国NASA研究所[70]用激光加热浮区法(laser heated floating zone, LHFZ)制备的Al2O3/ZrO2(Y2O3)共晶陶瓷纤维强度高达2 GPa,1 560 ℃热处理24 h后,强度无明显降低。

4.2 氧化铝基共晶陶瓷的硬度、断裂韧性及强韧化研究苏海军等[72-73]采用LZM法成功制备出组织超细化的棒状及片状Al2O3/YAG和Al2O3/YAG/ZrO2共晶陶瓷。硬度和断裂韧性分别达到17.5 GPa和3.6 MPa·m1/2(Al2O3/YAG共晶)和18.67 GPa,8.0 MPa·m1/2(Al2O3/YAG/ZrO2共晶)[74]。聂颖等[75]采用水平定向凝固法(horizontal directional solidification, HDS)制备的大尺寸块状Al2O3/YAG共晶陶瓷室温硬度、断裂韧性分别为16.79 GPa和3.07 MPa·m1/2。Fan等[16]利用LAM技术制备的Al2O3/YAG/ZrO2共晶陶瓷硬度高达18.9 GPa,断裂韧性为3.84 MPa·m1/2。不同方法制备的氧化物凝固共晶陶瓷硬度和断裂韧性如表 3所示。总体来讲,高硬度、低韧性是氧化物共晶陶瓷的显著特点,是制约该类材料工程化应用的关键所在。

研究发现,细化组织能够减小材料内部原始微裂纹的尺寸,有效提高陶瓷断裂韧性。Yan等[50]通过超声辅助成形将共晶间距细化到约70 nm,断裂韧性由6.52 MPa·m1/2增加到7.67 MPa·m1/2。随后,加工过程中向原料粉末中混入了质量分数为4%的C纤维[76],将所得试样的共晶间距进一步细化到约50 nm,断裂韧性提升至8.7 MPa·m1/2。Wu等[32]在制备Al2O3/YAG共晶陶瓷时,对基板进行水冷,提高加工过程基板冷却速率,使得共晶间距由0.96 μm减小到0.21 μm,硬度由19.44 GPa增加到21.50 GPa, 断裂韧性由5.40 MPa·m1/2增加到5.86 MPa·m1/2。苏海军等[15]在Al2O3/YAG/ZrO2三元共晶陶瓷制备过程中,通过ZrO2相变增韧及裂纹偏转机制,提高断裂韧性至8 MPa·m1/2。

5 结论超高温氧化铝基共晶陶瓷以其优异的高温综合力学性能,在航空航天领域具有巨大的发展潜力。以高推比发动机热端部件关键核心材料的重大需求牵引为导向,突破多元复相氧化物共晶陶瓷定向凝固控制难、组织均匀性差及韧性低的关键瓶颈问题迫在眉睫。开展高性能氧化铝基共晶复相陶瓷高梯度定向凝固技术与组织均细化,强韧化及取向可控研究将为实现航空航天1 600 ℃以上富氧环境长时工作的高温结构材料与构件的研发和应用奠定技术与理论基础。为加快突破高性能、强韧化、超高温氧化物陶瓷的制备瓶颈,目前仍有以下几方面有待进一步探索和突破:

1) 氧化铝基共晶陶瓷定向凝固温度场、应力场控制与凝固缺陷抑制。结合多种数值模拟技术,获得不同加工条件下温度场、应力场、流场等分布规律,优化工艺及探明凝固机理。

2) 氧化铝基共晶陶瓷定向凝固组织和晶体取向控制及选择机理。探究共晶单晶相生长热力学和动力学行为,开展单晶生长取向控制,进一步探索强各向异性共晶陶瓷非平衡凝固条件下的晶体取向生长选择机理。

3) 高熔化熵多元复相氧化物小平面共晶生长模型与生长形态转变机制。探究高熔化熵氧化物共晶陶瓷高温度梯度下小平面相复杂生长形态的转变机制并建立共晶生长模型。

4) 相界面调控定向凝固微/纳米结构共晶陶瓷强韧化机制。探明以共晶单晶相界面结合为基础的氧化物多元复相陶瓷强韧化和高温性能失效机理,建立多尺度界面、多层次结构设计优化和相界面结构匹配关系,探索协同提升共晶陶瓷强度和韧性的新方法。

| [1] | HIRANO K. Application of eutectic composites to gas turbine system and fundamental fracture properties up to 1 700℃[J]. Journal of the European Ceramic Society, 2005, 25(8): 1191-1199. DOI:10.1016/j.jeurceramsoc.2005.01.003 |

| [2] | NAKAGAWA N, OHTSUBO H, MITANI A, et al. High temperature strength and thermal stability for melt growth composite[J]. Journal of the European Ceramic Society, 2005, 25: 1251-1257. DOI:10.1016/j.jeurceramsoc.2005.01.030 |

| [3] | REN Q, SU H, ZHANG J, et al. Rapid eutectic growth of Al2O3/Er3Al5O12 nanocomposite prepared by a new method: melt falling-drop quenching[J]. Scripta Materialia, 2016, 125: 39-43. DOI:10.1016/j.scriptamat.2016.07.028 |

| [4] | SU H, ZHANG J, YU J, et al. Directional solidification and microstructural development of Al2O3/GdAlO3 eutectic ceramic in situ composite under rapid growth conditions[J]. Journal of Alloys and Compounds, 2011, 509(12): 4420-4425. DOI:10.1016/j.jallcom.2011.01.107 |

| [5] | WAKU Y, NAKAGAWA N, KOBAYASHI K, et al. Innovative manufacturing process of MGC components for ultra-high efficiency gas turbine systems[C]//Proceedings of ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 2004 |

| [6] | WAKU Y, NAKAGAWA N, WAKAMOTO T, et al. A ductile ceramic eutectic composite with high strength at 1 873 K[J]. Nature, 1997, 389: 49-52. DOI:10.1038/37937 |

| [7] | LEE J H, YOSHIKAWA A, DURBIN S D, et al. Microstructure of Al2O3/ZrO2 eutectic fibers grown by the micro-pulling down method[J]. Journal of Crystal Growth, 2001, 222: 791-796. DOI:10.1016/S0022-0248(00)00998-2 |

| [8] | BENAMARA O, CHERIF M, DUFFAR T, et al. Microstructure and crystallography of Al2O3-Y3Al5O12-ZrO2 ternary eutectic oxide grown by the micropulling down technique[J]. Journal of Crystal Growth, 2015, 429: 27-34. DOI:10.1016/j.jcrysgro.2015.07.020 |

| [9] | LEE J H, YOSHIKAWA A, FUKUDA T, et al. Growth and characterization of Al2O3/Y3Al5O12/ZrO2 ternary eutectic fibers[J]. Journal of Crystal Growth, 2001, 231: 115-120. DOI:10.1016/S0022-0248(01)01375-6 |

| [10] | ANDREETA E R M, ANDREETA M R B, HERNANDES A C. Laser heated pedestal growth of Al2O3/GdAlO3 eutectic fibers[J]. Journal of Crystal Growth, 2002, 234: 782-785. DOI:10.1016/S0022-0248(01)01764-X |

| [11] | LAIDOUNE A, LEBBOU K, BAHLOUL D. Microstructure of the yttria doped Al2O3-ZrO2 eutectic fibers grown by the laser heated pedestal growth(LHPG) method[J]. Journal of Crystal Growth, 2013, 380: 224-227. DOI:10.1016/j.jcrysgro.2013.06.026 |

| [12] | SU H, REN Q, ZHANG J, et al. Microstructures and mechanical properties of directionally solidified Al2O3/GdAlO3 eutectic ceramic by laser floating zone melting with high temperature gradient[J]. Journal of the European Ceramic Society, 2017, 37: 1617-1626. DOI:10.1016/j.jeurceramsoc.2016.11.041 |

| [13] | FAN G, SU H, ZHANG J, et al. Microstructure and cytotoxicity of Al2O3-ZrO2 eutectic bioceramics with high mechanical properties prepared by laser floating zone melting[J]. Ceramics International, 2018, 44(15): 17978-17985. DOI:10.1016/j.ceramint.2018.06.275 |

| [14] | SU H, WANG E, REN Q, et al. Microstructure tailoring and thermal stability of directionally solidified Al2O3/GdAlO3 binary eutectic ceramics by laser floating zone melting[J]. Ceramics International, 2018, 44(7): 7908-7916. DOI:10.1016/j.ceramint.2018.01.228 |

| [15] | SU H, ZHANG J, CUI C, et al. Rapid solidification of Al2O3/Y3Al5O12/ZrO2 eutectic in situ composites by laser zone remelting[J]. Journal of Crystal Growth, 2007, 307: 448-456. DOI:10.1016/j.jcrysgro.2007.06.029 |

| [16] | FAN Z, ZHAO Y, TAN Q, et al. Nanostructured Al2O3-YAG-ZrO2 ternary eutectic components prepared by laser engineered net shaping[J]. Acta Materialia, 2019, 170: 24-37. DOI:10.1016/j.actamat.2019.03.020 |

| [17] | LIU H, SU H, SHEN Z, et al. One-step additive manufacturing and microstructure evolution of melt-grown Al2O3/GdAlO3/ZrO2 eutectic ceramics by laser directed energy deposition[J]. Journal of the European Ceramic Society, 2021, 41: 3547-3558. DOI:10.1016/j.jeurceramsoc.2021.01.047 |

| [18] | LIU H, SU H, SHEN Z, et al. Preparation of large-size Al2O3/GdAlO3/ZrO2 ternary eutectic ceramic rod by laser directed energy deposition and its microstructure homogenization mechanism[J]. Journal of Material Science & Technology, 2021, 85: 218-223. |

| [19] | LIU H, SU H, SHEN Z, et al. Direct formation of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics by selective laser melting: microstructure evolutions[J]. Journal of the European Ceramic Society, 2018, 38: 5144-5152. DOI:10.1016/j.jeurceramsoc.2018.07.040 |

| [20] | NIU F, WU D, MA G, et al. Nanosized microstructure of Al2O3-ZrO2(Y2O3) eutectics fabricated by laser engineered net shaping[J]. Scripta Materialia, 2015, 95: 39-41. DOI:10.1016/j.scriptamat.2014.09.026 |

| [21] | WAKU Y, NAKAGAWA N, WAKAMOTO T, et al. High-temperature strength and thermal stability of a unidirectionally solidified Al2O3/YAG eutectic composite[J]. Journal of Materials Science, 1998, 33: 1217-1225. DOI:10.1023/A:1004377626345 |

| [22] | LIU H, SU H, SHEN Z, et al. Insights into high thermal stability of laser additively manufactured Al2O3/GdAlO3/ZrO2 eutectic ceramics under high temperatures[J]. Additive Manufacturing, 2021, 48: 102425. DOI:10.1016/j.addma.2021.102425 |

| [23] | LLORCA J, ORERA V M. Directionally solidified eutectic ceramic oxides[J]. Progress in Materials Science, 2006, 51: 711-809. DOI:10.1016/j.pmatsci.2005.10.002 |

| [24] | PARADIS P F, ISHIKAWA T. Surface tension and viscosity measurements of liquid and undercooled alumina by containerless techniques[J]. Japanese Journal of Applied Physics, 2005, 44: 5082-5085. DOI:10.1143/JJAP.44.5082 |

| [25] | ZHOU X, LIU X, ZHANG D, et al. Balling phenomena in selective laser melted tungsten[J]. Journal of Materials Processing Technology, 2015, 222: 33-42. DOI:10.1016/j.jmatprotec.2015.02.032 |

| [26] | SU H, LIU Y, REN Q, et al. Distribution control and formation mechanism of gas inclusions in directionally solidified Al2O3-Er3Al5O12-ZrO2 ternary eutectic ceramic by laser floating zone melting[J]. Journal of Material Science & Technology, 2021, 66: 21-27. |

| [27] |

申仲琳, 苏海军, 刘海方, 等. 超高温氧化物陶瓷激光增材制造技术与缺陷控制研究进展[J]. 复合材料学报, 2021, 38: 668-679.

SHEN Zhonglin, SU Haijun, LIU Haifang, et al. Research progress on laser additive manufacturing technology and its defect control for ultra-high temperature oxide ceramics[J]. Acta Materiae Compositae Sinica, 2021, 38: 668-679. (in Chinese) |

| [28] | YAN S, HUANG Y, ZHAO D, et al. 3D printing of nano-scale Al2O3-ZrO2 eutectic ceramic: principle analysis and process optimization of pores[J]. Additive Manufacturing, 2019, 28: 120-126. DOI:10.1016/j.addma.2019.04.024 |

| [29] | SU H, ZHANG J, LIU L, et al. Rapid growth and formation mechanism of ultrafine structural oxide eutectic ceramics by laser direct forming[J]. Applied Physics Letters, 2011, 99: 221913. DOI:10.1063/1.3664108 |

| [30] | LI F, LIU Z, LI B, et al. Pore formation model for direct laser deposition of Al2O3-ZrO2 ceramic[J]. Journal of the European Ceramic Society, 2022, 42: 207-215. DOI:10.1016/j.jeurceramsoc.2021.09.042 |

| [31] | LIU H, SU H, SHEN Z, et al. Effect of scanning speed on the solidification process of Al2O3/GdAlO3/ZrO2 eutectic ceramics in a single track by selective laser melting[J]. Ceramics International, 2019, 45: 17252-17257. DOI:10.1016/j.ceramint.2019.05.281 |

| [32] | WU D, LU F, ZHAO D, et al. Effect of doping SiC particles on cracks and pores of Al2O3-ZrO2 eutectic ceramics fabricated by directed laser deposition[J]. Journal of Materials Science, 2019, 54: 9321-9330. DOI:10.1007/s10853-019-03555-z |

| [33] | FERRAGE L, BERTRAND G, LENORMAND P. Dense yttria-stabilized zirconia obtained by direct selective laser sintering[J]. Additive Manufacturing, 2018, 21: 472-478. DOI:10.1016/j.addma.2018.02.005 |

| [34] | ZHANG K, LIU T, LIAO W, et al. Influence of laser parameters on the surface morphology of slurry-based Al2O3 parts produced through selective laser melting[J]. Rapid Prototyping Journal, 2018, 24: 333-341. DOI:10.1108/RPJ-12-2016-0201 |

| [35] | NIU F, WU D, YAN S, et al. Process optimization for suppressing cracks in laser engineered net shaping of Al2O3 ceramics[J]. The Journal of the Minerals, Metals & Materials Society, 2017, 69: 557-562. |

| [36] | LIU Q, SONG B, LIAO H. Microstructure study on selective laser melting yttria stabilized zirconia ceramic with near IR fiber laser[J]. Rapid Prototyping Journal, 2014, 20: 346-354. DOI:10.1108/RPJ-12-2012-0113 |

| [37] | HU Y, NING F, CONG W, et al. Ultrasonic vibration-assisted laser engineering net shaping of ZrO2-Al2O3 bulk parts: effects on crack suppression, microstructure, and mechanical properties[J]. Ceramics International, 2018, 44: 2752-2760. DOI:10.1016/j.ceramint.2017.11.013 |

| [38] |

刘翰超, 卢凡, 马广义, 等. 恒温基底对Al2O3基共晶陶瓷组织及硬度的影响[J]. 光电工程, 2017, 44: 1194-1199.

LIU Hanchao, LU Fan, MA Guangyi, et al. Effect of constant temperature substrate on microstructure and hardness of Al2O3-based eutectic ceramics[J]. Opto-Electronic Engineering, 2017, 44: 1194-1199. (in Chinese) |

| [39] | MA W, ZHANG J, SU H, et al. Theoretical prediction and experimental comparison for eutectic growth of Al2O3/GdAlO3 faceted eutectics[J]. Journal of the European Ceramic Society, 2019, 39: 3837-3842. DOI:10.1016/j.jeurceramsoc.2019.05.014 |

| [40] | SU H, SHEN Z, REN Q, et al. Evolutions of rod diameter, molten zone and temperature gradient of oxide eutectic ceramics during laser floating zone melting[J]. Ceramics International, 2020, 46: 18750-18757. DOI:10.1016/j.ceramint.2020.04.190 |

| [41] | MA W, ZHANG J, SU H, et al. Microstructure transformation from irregular eutectic to complex regular eutectic in directionally solidified Al2O3/GdAlO3/ZrO2 ceramics by laser floating zone melting[J]. Journal of the European Ceramic Society, 2016, 36: 1447-1454. DOI:10.1016/j.jeurceramsoc.2015.12.023 |

| [42] | MA W, ZHANG J, SU H, et al. Phase growth patterns for Al2O3/GdAlO3 eutectics over wide ranges of compositions and solidification rates[J]. Journal of Materials Science & Technology, 2021, 65: 89-98. |

| [43] | MA W, SU H, ZHANG J, et al. Effects of composition and solidification rate on growth striations in laser floating zone melted Al2O3/GdAlO3 eutectic ceramics[J]. Journal of the American Ceramic Society, 2018, 101: 3337-3346. DOI:10.1111/jace.15507 |

| [44] | YAN S, WU D, MA G, et al. Formation mechanism and process optimization of nano Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS)[J]. Ceramics International, 2017, 43: 14742-14747. DOI:10.1016/j.ceramint.2017.07.214 |

| [45] | REN Q, SU H, ZHANG J, et al. Microstructure control, competitive growth and precipitation rule in faceted Al2O3/Er3Al5O12 eutectic in situ composite ceramics prepared by laser floating zone melting[J]. Journal of the European Ceramic Society, 2019, 39: 1900-1908. DOI:10.1016/j.jeurceramsoc.2019.01.015 |

| [46] | REN Q, SU H, ZHANG J, et al. Eutectic growth behavior with regular arrangement in the faceted Al2O3/Er3Al5O12 irregular eutectic system at low growth rate[J]. Scripta Materialia, 2019, 162: 49-53. DOI:10.1016/j.scriptamat.2018.10.030 |

| [47] |

吴东江, 孙贝, 牛方勇, 等. 激光近净成形不同颜色Al2O3陶瓷件微观组织及裂纹分析[J]. 硅酸盐学报, 2013, 41: 1621-1626.

WU Dongjiang, SUN Bei, NIU Fangyong, et al. Microstructure and crack in color Al2O3 samples by laser engineered net shaping[J]. Journal of the Chinese Ceramic Society, 2013, 41: 1621-1626. (in Chinese) |

| [48] | WU D, LIU H, LU F, et al. Al2O3-YAG eutectic ceramic prepared by laser additive manufacturing with water-cooled substrate[J]. Ceramics International, 2019, 45: 4119-4122. DOI:10.1016/j.ceramint.2018.11.032 |

| [49] | YAN S, WU D, NIU F, et al. Effect of ultrasonic power on forming quality of nano-sized Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS)[J]. Ceramics International, 2018, 44: 1120-1126. DOI:10.1016/j.ceramint.2017.10.067 |

| [50] | YAN S, WU D, NIU F, et al. Al2O3-ZrO2 eutectic ceramic via ultrasonic-assisted laser engineered net shaping[J]. Ceramics International, 2017, 43: 15905-15910. DOI:10.1016/j.ceramint.2017.08.165 |

| [51] | WANG X, WANG J Y, SUN L C, et al. Microstructure evolution of Al2O3/Y3Al5O12 eutectic crystal during directional solidification[J]. Scripta Materialia, 2015, 108: 31-34. DOI:10.1016/j.scriptamat.2015.05.038 |

| [52] | MA X, LI J, PENG Z, et al. Interpenetrating network-structured Al2O3-Y3Al5O12 eutectic composite grown by containerlessly directional solidification process[J]. Crystal Growth & Design, 2015, 15: 5652-5655. |

| [53] | SAKATA S, MITANI A, SHIMIZU K, et al. Crystallographic orientation analysis and high temperature strength of melt growth compo-site[J]. Journal of the European Ceramic Society, 2005, 25: 1441-1445. DOI:10.1016/j.jeurceramsoc.2005.01.023 |

| [54] | FAN Z, ZHAO Y, TAN Q, et al. New insights into the growth mechanism of 3D-printed Al2O3-Y3Al5O12 binary eutectic composites[J]. Scripta Materialia, 2020, 178: 274-280. DOI:10.1016/j.scriptamat.2019.11.040 |

| [55] | LARREA A, FUENTE G F, MERINO R I, et al. ZrO2-Al2O3 eutectic plates produced by laser zone melting[J]. Journal of the European Ceramic Society, 2002, 22: 191-198. DOI:10.1016/S0955-2219(01)00279-5 |

| [56] | OHASHI Y, YASUI N, SUZUKI T, et al. Orientation relationships of unidirectionally aligned GdAlO3/Al2O3 eutectic fibers[J]. Journal of the European Ceramic Society, 2014, 34: 3849-3857. DOI:10.1016/j.jeurceramsoc.2014.04.042 |

| [57] | MAZEROLLES L, PERRIERE L, LARTIGUE KORINEK S, et al. Microstructures, crystallography of interfaces, and creep behavior of melt-growth composites[J]. Journal of the European Ceramic Society, 2008, 28: 2301-2308. DOI:10.1016/j.jeurceramsoc.2008.01.014 |

| [58] | MESA M C, SERRANO-ZABALETA S, OLIETE P B, et al. Microstructural stability and orientation relationships of directionally solidified Al2O3-Er3Al5O12-ZrO2 eutectic ceramics up to 1600℃[J]. Journal of the European Ceramic Society, 2014, 34: 2071-2080. DOI:10.1016/j.jeurceramsoc.2013.11.011 |

| [59] | WANG X, ZHONG Y, SUN Q, et al. Crystallography and interfacial structure in a directionally solidified Al2O3/Y3Al5O12/ZrO2 eutectic crystal[J]. Scripta Materialia, 2018, 145: 23-27. DOI:10.1016/j.scriptamat.2017.10.008 |

| [60] | WANG X, WANG D, ZHANG H, et al. Mechanism of eutectic growth in directional solidification of an Al2O3/Y3Al5O12 crystal[J]. Scripta Materialia, 2016, 116: 44-48. DOI:10.1016/j.scriptamat.2016.01.020 |

| [61] | MURAYAMA Y, HANADA S, LEE J H, et al. High-temperature strength of directionally solidified Al2O3/YAG/ZrO2 eutectic composite[C]//Materials Science Forum, Switzerland, 2005 |

| [62] | YOSHIMURA M, SAKATA S, YAMADA S, et al. The growth of Al2O3/YAG: Ce melt growth composite by the vertical bridgman technique using an a-axis Al2O3 seed[J]. Journal of Crystal Growth, 2015, 427: 16-20. DOI:10.1016/j.jcrysgro.2015.06.023 |

| [63] | WANG X, ZHONG Y, WANG D, et al. Effect of interfacial energy on microstructure of a directionally solidified Al2O3/YAG eutectic ceramic[J]. Journal of the American Ceramic Society, 2018, 101: 1029-1035. DOI:10.1111/jace.15317 |

| [64] | WAKU Y, SAKATA S, MITANI A, et al. Temperature dependence of flexural strength and microstructure of Al2O3/Y3Al5O12/ZrO2 ternary melt growth composites[J]. Journal of Materials Science, 2002, 37: 2975-2982. DOI:10.1023/A:1016073115264 |

| [65] | MURAYAMA Y, HANADA S, LEE J H, et al. Microstructure and high-temperature strength of directionally solidified Al2O3/YAG/ZrO2 eutectic composite[J]. Materials Transactions, 2004, 45: 303-306. DOI:10.2320/matertrans.45.303 |

| [66] | LEE J H, YOSHIKAWA A, MURAYAMA Y, et al. Microstructure and mechanical properties of Al2O3/Y3Al5O12/ZrO2 ternary eutectic materials[J]. Journal of the European Ceramic Society, 2005, 25: 1411-1417. DOI:10.1016/j.jeurceramsoc.2005.01.034 |

| [67] | PASTOR J Y, LLORCA J, SALAZAR A, et al. Mechanical properties of melt-grown alumina-yttrium aluminum garnet eutectics up to 1 900 K[J]. Journal of the American Ceramic Society, 2005, 88: 1488-1495. DOI:10.1111/j.1551-2916.2005.00265.x |

| [68] | OLIETE P B, PENA J I, LARREA A, et al. Ultra-high-strength nanofibrillar Al2O3-YAG-YSZ eutectics[J]. Advanced Materials, 2007, 19: 2313-2318. DOI:10.1002/adma.200602379 |

| [69] | PARK D Y, YANG J M. Effect of the microstructure on the mechanical properties of a directionally solidified Y3Al5O12/Al2O3 eutectic fiber[J]. Journal of Materials Science, 2001, 36: 5593-5601. DOI:10.1023/A:1012561531552 |

| [70] | COURTRIGHT E L, LABORATORY P N, HAGGERTY J S, et al. Controlling microstructure in ZrO2/(Y2O3)-Al2O3 eutectic fibers[J]. Ceramic Engineering and Science Proceedings, 1993, 14: 671-681. |

| [71] | WAKU Y. A new ceramic eutectic composite with high strength at 1 873 K[J]. Advanced Materials, 1998, 10(8): 615-617. DOI:10.1002/(SICI)1521-4095(199805)10:8<615::AID-ADMA615>3.0.CO;2-T |

| [72] | SU H, ZHANG J, MA W, et al. In situ fabrication of highly-dense Al2O3/YAG nanoeutectic composite ceramics by a modified laser surface processing[J]. Journal of the European Ceramic Society, 2014, 34: 739-744. DOI:10.1016/j.jeurceramsoc.2013.10.014 |

| [73] | ZHANG J, SU H, SONG K, et al. Microstructure, growth mechanism and mechanical property of Al2O3-based eutectic ceramic in situ composites[J]. Journal of the European Ceramic Society, 2011, 31: 1191-1198. DOI:10.1016/j.jeurceramsoc.2010.11.008 |

| [74] | SU H, ZHANG J, CUI C, et al. Rapid solidification behaviour of Al2O3/Y3Al5O12(YAG) binary eutectic ceramic in situ composites[J]. Materials Science and Engineering A, 2008, 479: 380-388. DOI:10.1016/j.msea.2007.06.080 |

| [75] | NIE Y, ZHANG M, LIU Y, et al. Microstructure and mechanical properties of Al2O3/YAG eutectic ceramic grown by horizontal directional solidification method[J]. Journal of Alloys and Compounds, 2016, 657: 184-191. DOI:10.1016/j.jallcom.2015.10.089 |

| [76] | YAN S, WU D, HUANG Y, et al. C fiber toughening Al2O3-ZrO2 eutectic via ultrasonic-assisted directed laser deposition[J]. Materials Letters, 2019, 235: 228-231. DOI:10.1016/j.matlet.2018.10.047 |

| [77] | MAZEROLLES L, PIQUET N, TRICHET M F, et al. New microstructures in ceramic materials from the melt for high temperature applications[J]. Aerospace Science and Technology, 2008, 12: 499-505. DOI:10.1016/j.ast.2007.12.002 |

| [78] | LARREA A, ORERA V M, MERINO R I, et al. Microstructure and mechanical properties of Al2O3-YSZ and Al2O3-YAG directionally solidified eutectic plates[J]. Journal of the European Ceramic Society, 2005, 25: 1419-1429. DOI:10.1016/j.jeurceramsoc.2005.01.021 |

| [79] | LIU Z, SONG K, GAO B, et al. Microstructure and mechanical properties of Al2O3/ZrO2 directionally solidified eutectic ceramic prepared by laser 3D printing[J]. Journal of Materials Science & Technology, 2016, 32: 320-325. |

2. Research & Development Institute of Northwestern Polytechnical University, Shenzhen 518057, China