Research on Software Reliability of Embedded CNC System Using Time Sequence Traceability

-

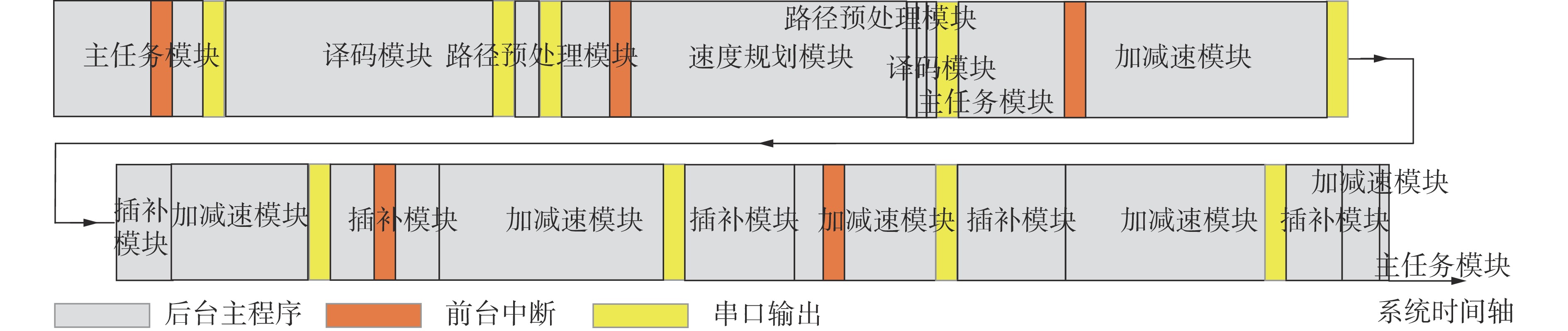

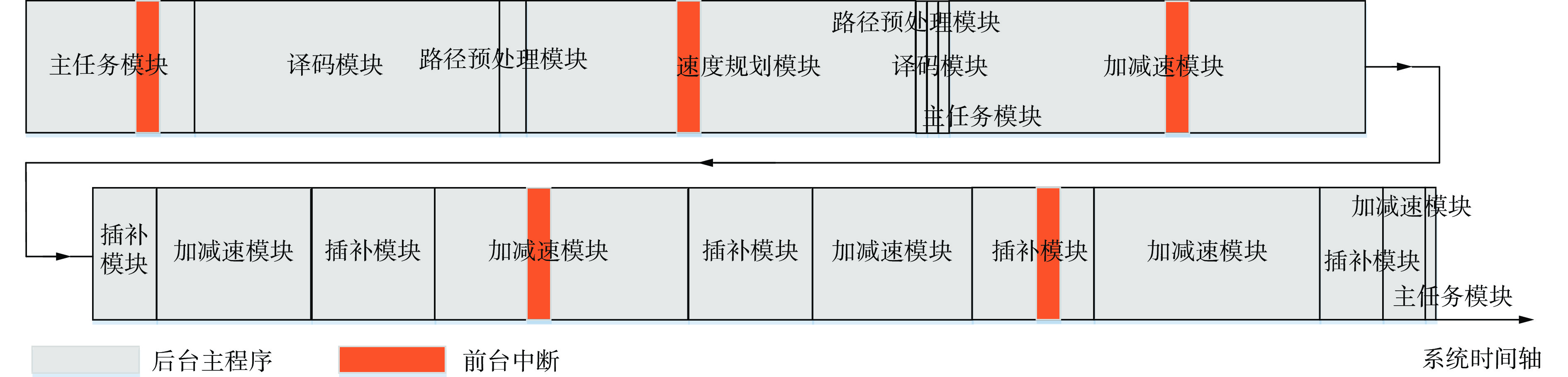

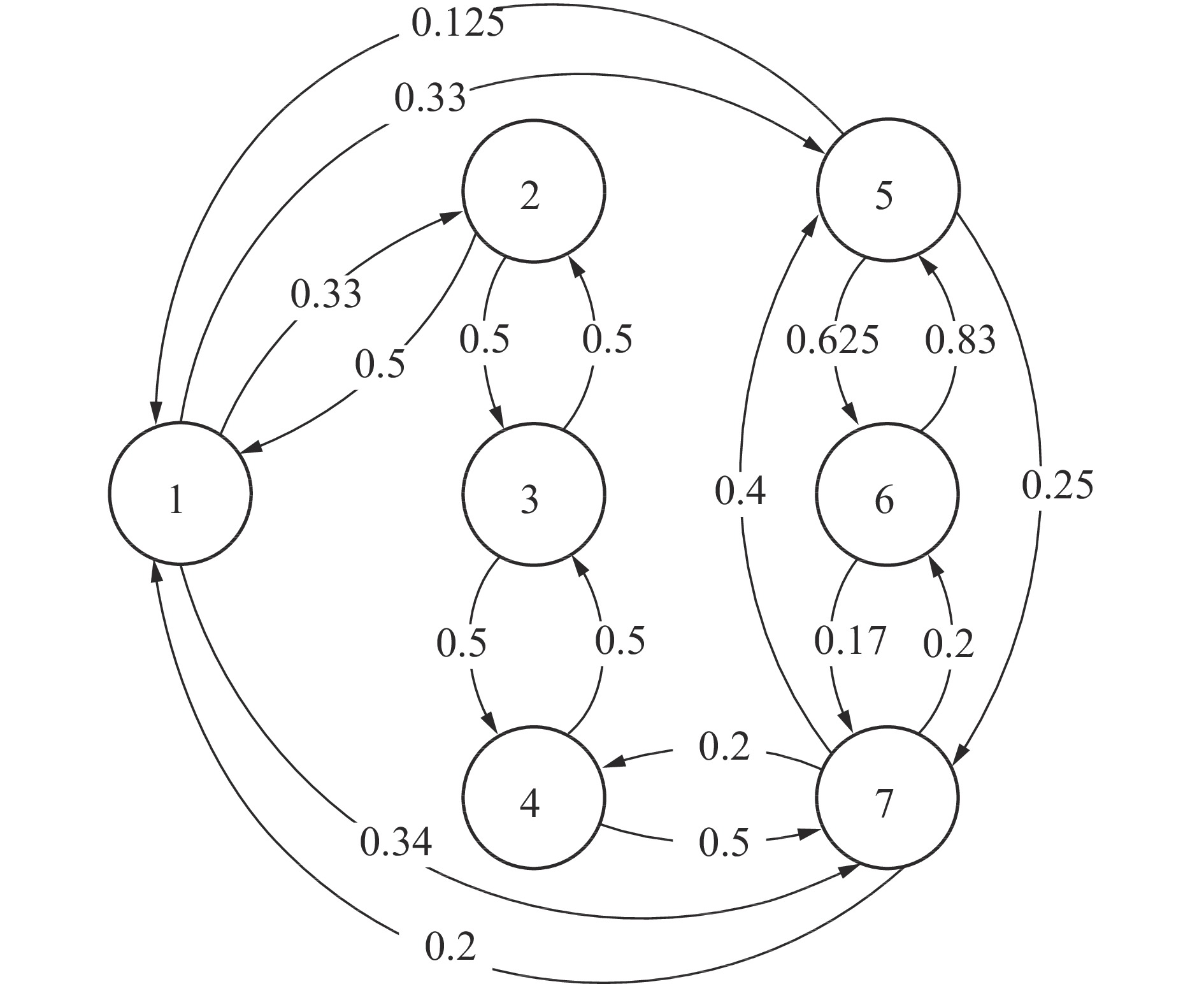

摘要: 嵌入式数控软件的可靠性是一个重要问题,由于其包含电机驱动、插补中断等诸多模块,程序运行逻辑复杂,软件各模块的执行顺序具有随机性,软件系统可靠性评估困难。采用马氏链模型开展嵌入式数控软件的可靠性评估,提出时序溯源的方法,重溯程序运行时序图,构建运行剖面,量化转移概率;采用时间补偿的程序运行逻辑恢复方法,消除关键点数据的监测、输出对系统运行实时性影响,还原CPU在时间轴上的运行逻辑顺序。最后通过实例验证该方法的可行性。Abstract: The reliability of embedded CNC (Computer Numerical Control) software is an important issue. Because it contains many modules such as motor drive and interpolation interruption, the programs′ operation logic is complicated, and the execution sequence of the software modules is random, so the reliability evaluation of the software system is difficult. We adopted the Markov chain model to carry out the reliability evaluation of embedded CNC software, proposed a method of time sequence traceability, re-traced the program running sequence diagram, constructed the running profile and quantified the transition probability; Then we adopted a time-compensated program operation logic recovery method to eliminate the impact of key point data monitoring and output on the real-time performance of the system, and restore the logical sequence of the CPU on the time axis. Finally, an example is used to verify the feasibility of the method.

-

Key words:

- timing traceability /

- embedded CNC system /

- markov chain /

- time compensation

-

表 1 各功能模块对应数字序号

功能模块 序号 主任务模块 1 译码模块 2 路径预处理模块 3 速度规划模块 4 加减速模块 5 插补模块 6 前台中断 7 表 2 各功能模块的运行时间及比例

功能模块 时间${t_i}$/μs 比例${k_i}$/% 主任务模块 31.10 6.310 译码模块 56.61 11.485 路径预处理模块 0.63 0.128 速度规划模块 72.99 14.808 加减速模块 233.30 47.332 插补模块 92.02 18.669 前台中断 6.25 1.268 总时间 492.90 1 -

[1] PENG C, MENG Y J, LAN L Y. Study on software reliability of numerical control system[J]. Applied Mechanics and Materials, 2013, 278-280: 2085-2089. doi: 10.4028/www.scientific.net/AMM.278-280.2085 [2] GU Y, WANG Y Q, LIN J Q, et al. Fault location in CNC system software based on the architecture expansion[J]. Tehnički Vjesnik, 2017, 24(2): 619-625. [3] GU Y K, ZHANG J, SHEN Y J, et al. Fault tree analysis method based on probabilistic model checking and discrete time Markov Chain[J]. Journal of Industrial and Production Engineering, 2019, 36(3): 146-153. doi: 10.1080/21681015.2019.1645050 [4] SINGH L K, VINOD G, TRIPATHI A K. Approach for parameter estimation in Markov model of software reliability for early prediction: a case study[J]. IET Software, 2015, 9(3): 65-75. doi: 10.1049/iet-sen.2014.0108 [5] 吴军, 邵新宇, 邓超. 隐马尔科夫链模型在装备运行可靠性预测中的应用[J]. 中国机械工程, 2010, 21(19): 2345-2349.WU J, SHAO X Y, DENG C. A HMC-based equipment operation reliability prediction with multiple observation sequences[J]. China Mechanical Engineering, 2010, 21(19): 2345-2349. (in Chinese) [6] 张文秀, 韩肖清, 宋述勇, 等. 计及源-网-荷不确定性因素的马尔科夫链风电并网系统运行可靠性评估[J]. 电网技术, 2018, 42(3): 762-771. doi: 10.13335/j.1000-3673.pst.2017.1475ZHANG W X, HAN X Q, SONG S Y, et al. Operational reliability evaluation of wind integrated power systems based on Markov Chain considering uncertainty factors of Source-Grid-Load[J]. Power System Technology, 2018, 42(3): 762-771. (in Chinese) doi: 10.13335/j.1000-3673.pst.2017.1475 [7] CALINESCU R, GHEZZI C, JOHNSON K, et al. Formal verification with confidence intervals to establish quality of service properties of software systems[J]. IEEE Transactions on Reliability, 2016, 65(1): 107-125. doi: 10.1109/TR.2015.2452931 [8] 周一耒, 于海波, 钟浩. 基于字节码插桩的多线程调试工具[J]. 计算机工程, 2016, 42(11): 83-88. doi: 10.3969/j.issn.1000-3428.2016.11.014ZHOU Y L, YU H B, ZHONG H. Multithreaded debugging tool based on bytecode instrumentation[J]. Computer Engineering, 2016, 42(11): 83-88. (in Chinese) doi: 10.3969/j.issn.1000-3428.2016.11.014 [9] LEE J, KANG S, KEUM C. Architecture-based software testing[J]. International Journal of Software Engineering and Knowledge Engineering, 2018, 28(1): 57-77. doi: 10.1142/S0218194018500031 [10] 钱超, 史跃东, 王校锋, 等. 基于马尔科夫模型的船舶设备多状态系统可靠性分析方法[J]. 船舶工程, 2017, 39(4): 57-60. doi: 10.13788/j.cnki.cbgc.2017.04.057QIAN C, SHI Y D, WANG X F, et al. Reliability analysis method of marine equipment multi-state system based on Markov model[J]. Ship Engineering, 2017, 39(4): 57-60. (in Chinese) doi: 10.13788/j.cnki.cbgc.2017.04.057 [11] SINGH L, RAJPUT H, VINOD G, et al. Computing transition probability in Markov Chain for early prediction of software reliability[J]. Quality and Reliability Engineering International, 2016, 32(3): 1253-1263. doi: 10.1002/qre.1793 [12] 唐佩佳, 谢永杰, 吴安波, 等. 基于马尔可夫链的构件软件可靠性评估模型[J]. 计算机应用, 2016, 36(S2): 262-265.TANG P J, XIE Y J, WU A B, et al. Reliability evaluation model based on Markov chain for component-based software[J]. Journal of Computer Applications, 2016, 36(S2): 262-265. (in Chinese) [13] 黄志刚, 谢锋云. 基于广义马尔科夫链模型的动柔度预测[J]. 机床与液压, 2014, 42(24): 67-70. doi: 10.3969/j.issn.1001-3881.2014.24.013HUANG Z G, XIE F Y. Dynamic compliance prediction based on generalized Markov Chain model[J]. Hydromechatronics Engineering, 2014, 42(24): 67-70. (in Chinese) doi: 10.3969/j.issn.1001-3881.2014.24.013 [14] 洪范. 系统软件可靠性[M]. 李璐祎, 译. 北京: 国防工业出版社, 2014PHAM H. System software reliability[M]. LI L Y, trans. Beijing: National Defense Industry Press, 2014. (in Chinese) -

下载:

下载: