Study on Numerical Simulation and Residual Stress in Multi-channel and Multi-layer Surfacing Welding

-

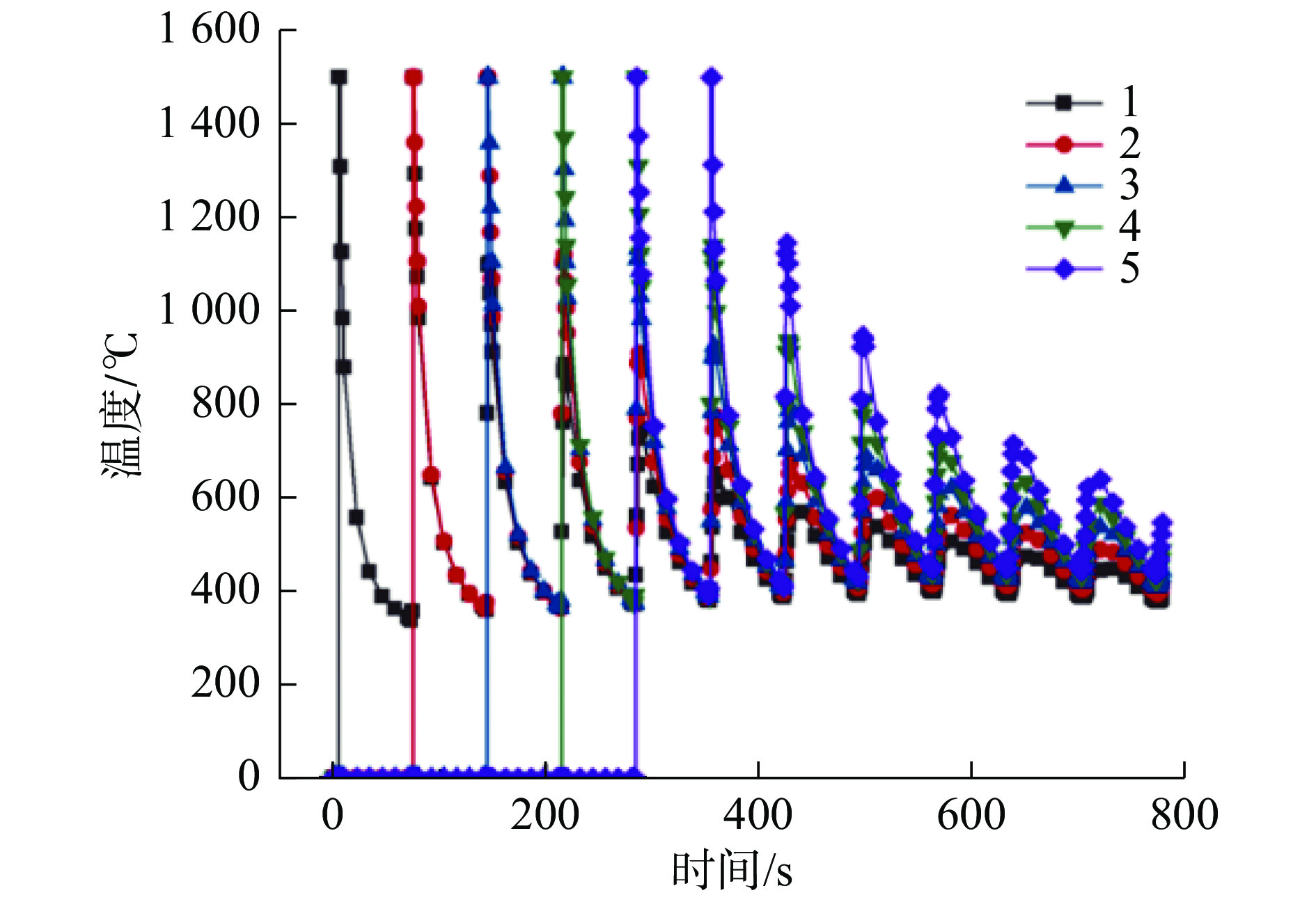

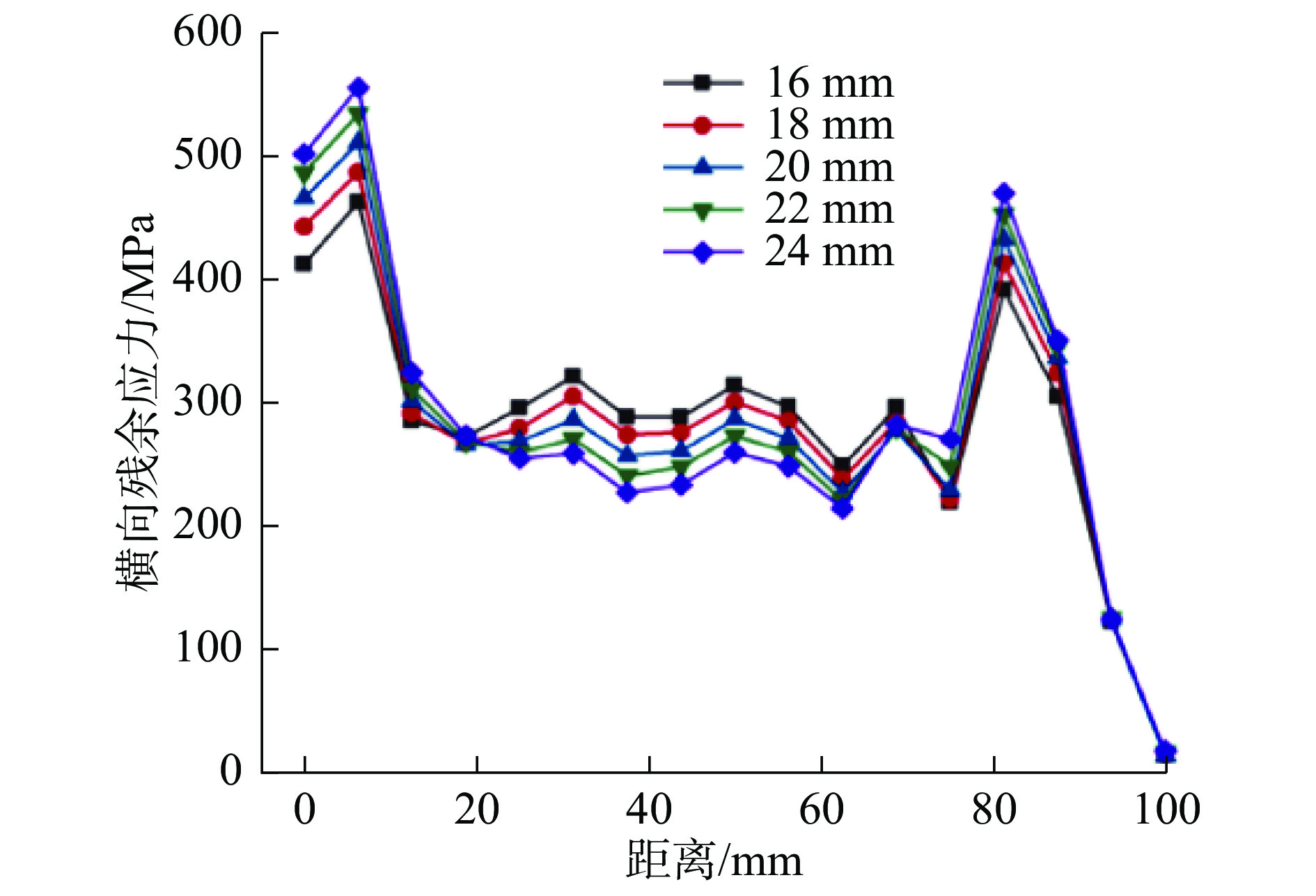

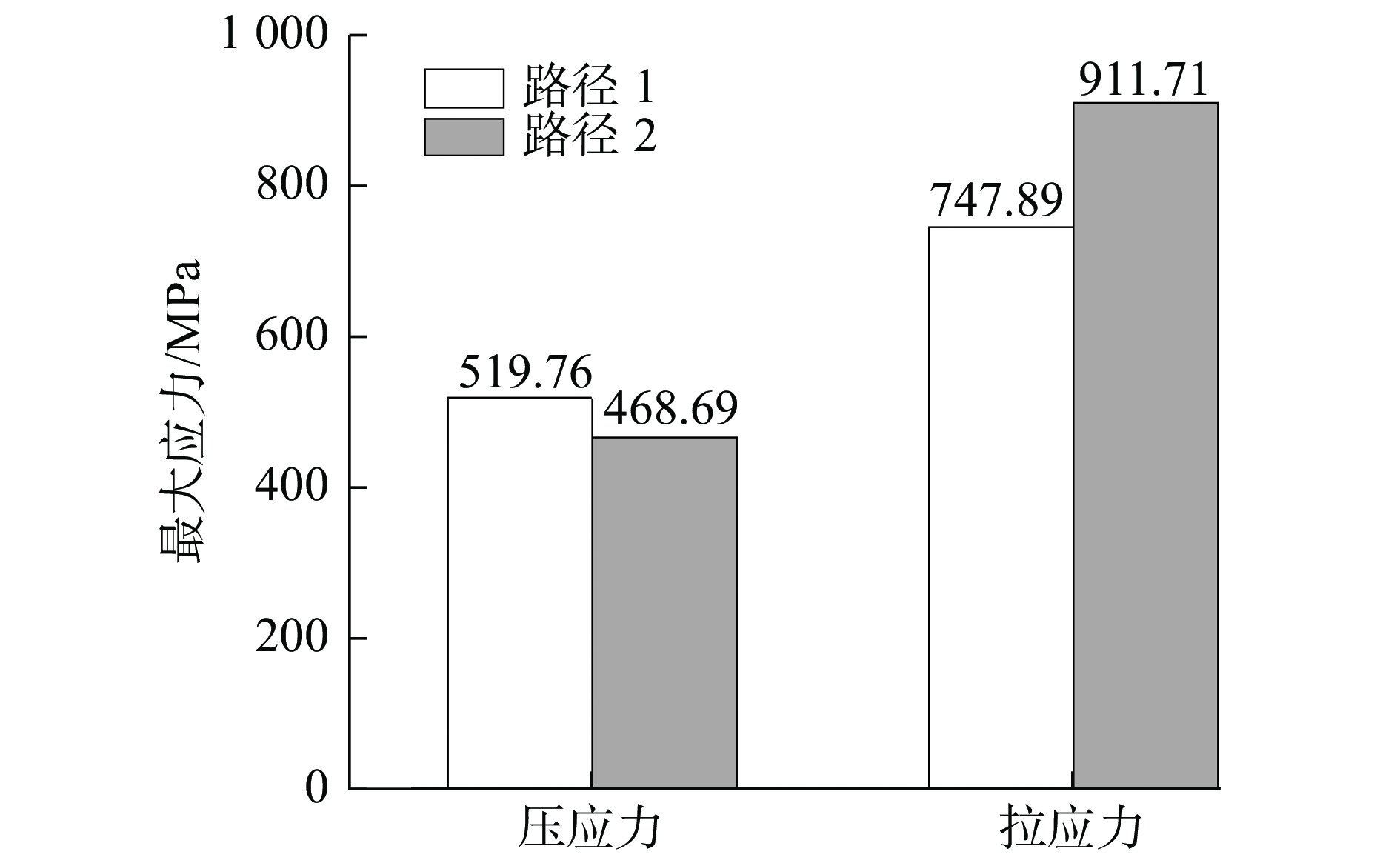

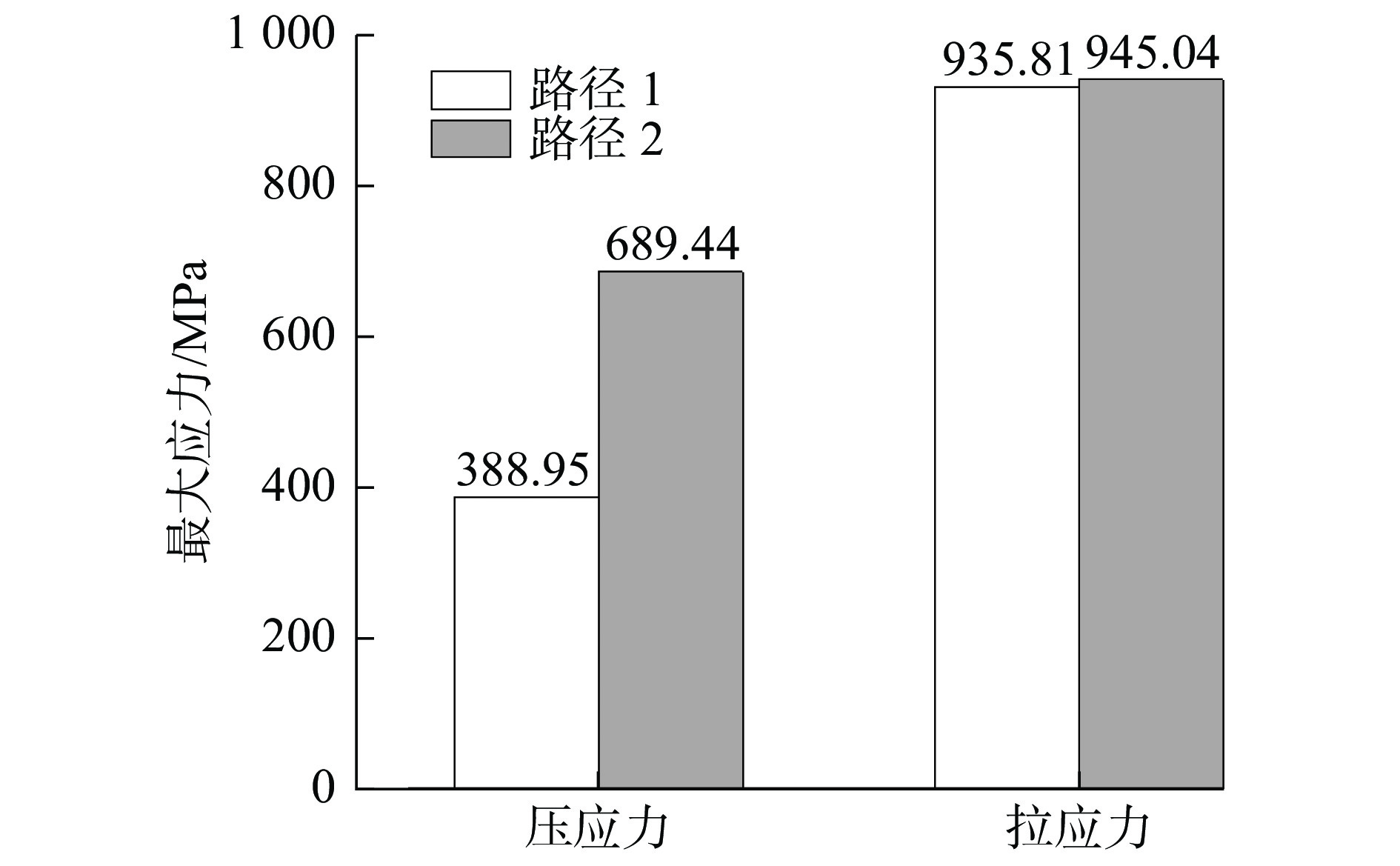

摘要: 本文利用Marc有限元软件对高温合金的多道多层堆焊过程进行了数值模拟,讨论了堆焊厚度和堆焊路径对焊后残余应力的影响。结果表明,堆焊厚度的增加会导致横向残余应力峰值增大,并使堆焊层局部应力的方向改变,从而受到多向应力作用,因此堆焊层在满足使用要求的前提下 ,堆焊厚度不易过大。同时,由于受到前后焊缝温度的影响,堆焊层间存在应力释放的现象。另外,对比了“逐道堆焊”和“逐层堆焊”过程中焊后残余应力分布情况。“逐层堆焊”相比于“逐道堆焊”所产生的残余应力分布更加均匀,且残余应力峰值更小。Abstract: In this paper, the multi-channel and multi-layer surfacing welding process of Superalloy was simulated via Marc finite element analysis software. The effect of the surfacing thickness and surfacing path on the residual stress after surfacing welding was emphatically discussed. The results showed that in the surfacing welding, the increase in surfacing thickness would lead to the increase in the peak value of the transverse residual stress and the change of the local stress direction inside the welding bead, which results in the surfacing layers are subjected to multi-directional stress. Therefore, on the premise of meeting the use requirements, the surfacing thickness is not suitable to be too large. And because of the influence of the temperature of the front and latter layers, there was a phenomenon of stress release between the surfacing layers. In addition, the residual stress distribution in the process of "channel-by-channel surfacing" and "layer-by-layer surfacing" were compared. The residual stress distribution of "layer-by-layer surfacing" was more uniform than that of "channel-by-channel surfacing", and the peak value of residual stress was smaller.

-

Key words:

- surfacing path /

- surfacing thickness /

- numerical simulation /

- residual stresses

-

表 1 铁基合金RMD248各元素的质量分数

% C Mn Si P S Ni Cr Mo Al W V Fe 0.25 1.61 0.72 0.013 0.004 1.5 5.51 1.69 0.21 1.04 0.24 Bal. 表 2 钴基高温合金JLCo32各元素的质量分数

% C Mn Si P S Ni Cr Mo Fe W Co 0.21 1 1 0.016 0.007 2.35 27.5 8.75 1.58 0.1 Bal. 表 3 基体材料RMD248和堆焊材料JLCo32性能参数

材料 温度

/℃热膨胀

系数/

10−6 ℃−1弹性

模量/

GPa导热系数/

[W·(m·℃)−1]比热容/

[J·(kg·℃)−1]屈服

强度/

MPaJLCo32 20 11 231 14.8 456 660 200 12.7 210 16.9 482 636 400 13.9 197 18.9 522 602 600 15 181 22.9 573 585 1000 16.5 160 29.8 685 502 1500 18.2 68 33.2 825 1 RMD248 20 11.5 34.8 461 1253 200 13.7 32.5 533 1250 400 15.2 31.8 24 611 1146 600 15.7 31.0 778 634 1000 16.1 21.2 778 202 1500 16.3 18.5 778 1 表 4 不同高度下的焊后残余应力峰值

堆焊高度/mm 横向残余应力/MPa 纵向残余应力/MPa 16 520.3 710.9 18 544.5 716.6 20 574.0 715.3 22 599.6 715.8 24 626.0 716.4 -

[1] 张建生, 卢顺, 董旭刚, 等. 模具堆焊工艺中焊缝形状预测及工艺参数优化研究进展[J]. 锻压装备与制造技术, 2020, 55(3): 126-129.ZHANG J S, LU S, DONG X G, et al. Research progress of weld seam shape prediction and process parameter optimization in die surfacing process[J]. China Metalforming Equipment & Manufacturing Technology, 2020, 55(3): 126-129. (in Chinese) [2] 王庆国. 模具的合金堆焊研究[J]. 铝加工, 2003(4): 44-45. doi: 10.3969/j.issn.1005-4898.2003.04.012WANG Q G. Study on bead welding for die[J]. Aluminium Fabrication, 2003(4): 44-45. (in Chinese) doi: 10.3969/j.issn.1005-4898.2003.04.012 [3] SHEN L, ZHOU J, XIONG Y B, et al. Study on the combination of cobalt-based superalloy and ferrous alloys by bimetal-layer surfacing technology in refabrication of large hot forging dies[J]. Journal of Alloys and Compounds, 2017, 714: 338-347. doi: 10.1016/j.jallcom.2017.04.253 [4] LU S, ZHOU J, ZHANG J S. Optimization of welding thickness on casting-steel surface for production of forging die[J]. The International Journal of Advanced Manufacturing Technology, 2015, 76(5-8): 1411-1419. doi: 10.1007/s00170-014-6371-9 [5] 卢顺. 铸钢基体双金属梯度制备锻模新方法基础及应用研究[D]. 重庆: 重庆大学, 2014LU S. The new method basis and application of the forging die with bimetal gradient layer on cast steel[D]. Chongqing: Chongqing University, 2014. (in Chinese) [6] 张建生. 大型超高强度钢模锻用锻模夹心层再制造方法基础及应用研究[D]. 重庆: 重庆大学, 2016ZHANG J S. Basis and application of multiple-layer sandwiched surfacing of large-scale forging die remanufacturing for ultra-high strength steel[D]. Chongqing: Chongqing University, 2016. (in Chinese) [7] XIA Y F, JIN L, CHENG Q, et al. A comparative study on the microstructures and mechanical properties between surfacing nickel-based superalloy and surfacing cobalt-based superalloy[J]. Materials Research Express, 2019, 6(9): 096589. doi: 10.1088/2053-1591/ab30b2 [8] 张国政. 基于ANSYS的柱塞堆焊焊接的残余应力分析研究[D]. 西安: 西安石油大学, 2014ZHANG G Z. Oil well pipe material liquid-solid two-phase flow erosion-corrosion studies[D]. Xi'an: Xi'an Shiyou University, 2014. (in Chinese) [9] 安超. 单层熔丝积材残余应力分布规律及打击消除机理研究[D]. 重庆: 重庆大学, 2019AN C. Study on distribution of residual stress of single-layer fuse-adding and elimination of stress by hammer peening[D]. Chongqing: Chongqing University, 2019. (in Chinese) [10] 李冬林. 焊接应力和变形的数值模拟研究[D]. 武汉: 武汉理工大学, 2003LI D L. Numerical simulation research on welding stress and deformation[D]. Wuhan: Wuhan University of Technology, 2003. (in Chinese) [11] SUN J H, WU C S, CHEN M A. Numerical analysis of transient temperature field and keyhole geometry in controlled pulse key-holing plasma arc welding[J]. Numerical Heat Transfer, Part A:Applications, 2013, 64(5): 416-434. doi: 10.1080/10407782.2013.784142 [12] SVANADZE M Z. The fundamental solution of the oscillation equations of the thermoelasticity theory of mixture of two elastic solids[J]. Journal of Thermal Stresses, 1996, 19(7): 633-648. doi: 10.1080/01495739608946199 [13] MOCHIZUKI M, HAYASHI M, HATTORI T. Welding residual stress estimation by inherent strain analysis and thermal elastic plastic analysis and its verification using neutron diffraction measurement[J]. Transactions of the Japan Society of Mechanical Engineers. Part A, 1997, 63(612): 1675-1680. doi: 10.1299/kikaia.63.1675 [14] 权国政, 施瑞菊, 刘乔, 等. 电弧熔丝单层单道积材残余应力模拟分析及锤击消除研究[J]. 材料导报, 2020, 34(14): 14154-14160. doi: 10.11896/cldb.19050113QUAN G Z, SHI R J, LIU Q, et al. Analysis and elimination of residual stress in single layer and single channel of arc fuse accumulation[J]. Materials Reports, 2020, 34(14): 14154-14160. (in Chinese) doi: 10.11896/cldb.19050113 [15] 黄霜, 杨晓益, 陈辉, 等. 5A06铝合金扫描激光填丝焊接头变形及应力分析[J]. 焊接学报, 2020, 41(2): 87-92. doi: 10.12073/j.hjxb.20190220001HUANG S, YANG X Y, CHEN H, et al. Analysis of deformation and stress of scanning laser wire filling welded 5A06 aluminum alloy joint[J]. Transactions of the China Welding Institution, 2020, 41(2): 87-92. (in Chinese) doi: 10.12073/j.hjxb.20190220001 [16] 张涛, 赵北君, 朱世富, 等. MSC Marc有限元软件在粉末成形中的应用[J]. 新疆大学学报(自然科学版), 2008, 25(4): 454-457.ZHANG T, ZHAO B J, ZHU S F, et al. Application of MSC Marc in powder-forming[J]. Journal of Xinjiang University (Natural Science Edition), 2008, 25(4): 454-457. (in Chinese) [17] SHI Q Y, LU A L, ZHAO H Y, et al. Effect of material properties at high temperature on efficiency and precision in numerical simulation for welding process[C]//International Conference on ComputationalEngineering Science, 2000: 655-660 [18] GOLDAK J, CHAKRAVARTI A, BIBBY M. A new finite element model for welding heat sources[J]. Metallurgical Transactions B, 1984, 15(2): 299-305. doi: 10.1007/BF02667333 [19] 董杰. 金属堆焊成形工艺参数优化与实验研究[D]. 乌鲁木齐: 新疆大学, 2019DONG J. Optimization and experimental study on process parameters of metal overlay welding[D]. Urumqi: Xinjiang University, 2019. (in Chinese) [20] ZHAO H H, ZHANG G J, YIN Z Q, et al. Three-dimensional finite element analysis of thermal stress in single-pass multi-layer weld-based rapid prototyping[J]. Journal of Materials Processing Technology, 2012, 212(1): 276-285. doi: 10.1016/j.jmatprotec.2011.09.012 -

下载:

下载: