Designing and Analyzing Performance of Lattice Energy Absorbing Device for Anti-impact Hydraulic Support

-

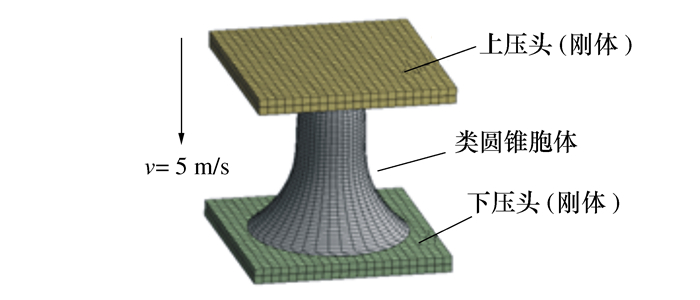

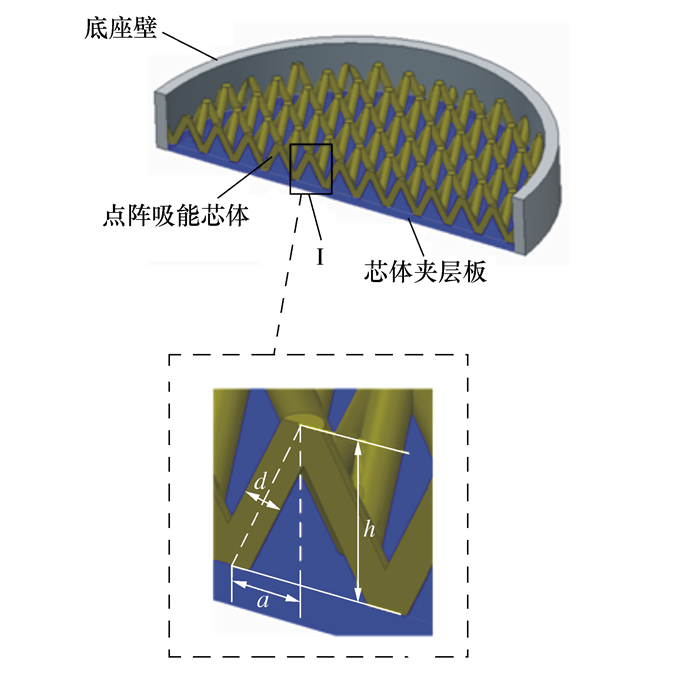

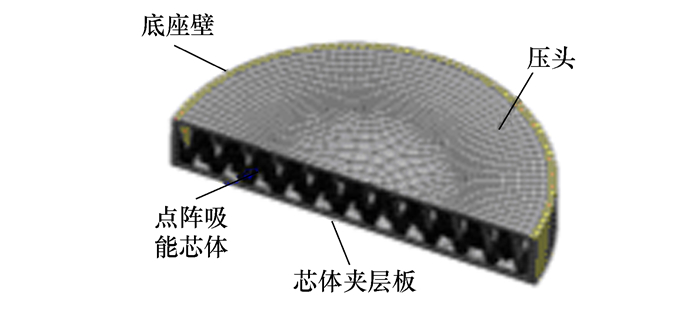

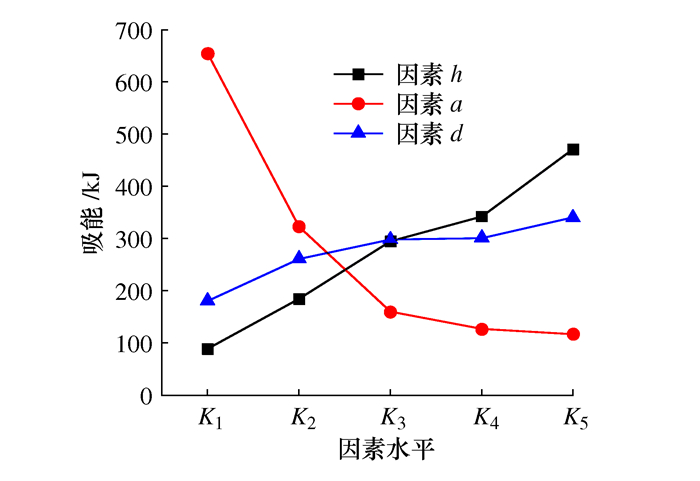

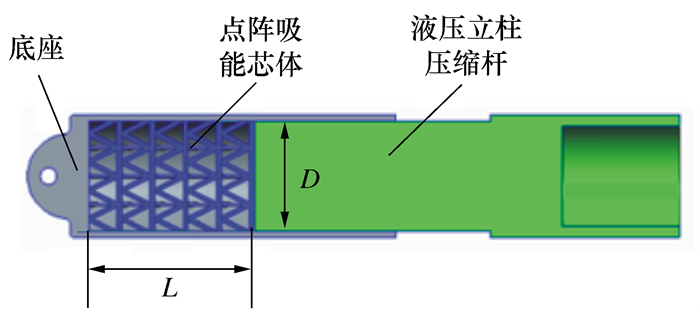

摘要: 为提高防冲液压支架的让位吸能大小, 提高防冲液压支架的安全性, 设计一种点阵让位吸能装置。采用有限元仿真的方式分别研究3种典型点阵胞体的比吸能及单位质量支撑力, 确定金字塔结构为最佳拓扑胞体结构。采用三因素五水平的正交实验分析胞体高度, 胞体立足倾斜宽度及胞体立足直径对点阵芯体的吸能大小及支撑力的影响规律, 确定最佳的胞体结构参数。通过仿真分析得到最佳结构参数的金字塔点阵吸能装置的总吸能为1 470 kJ, 支撑力为4 679.76 kN, 且支撑力较平稳。证明金字塔结构点阵吸能装置具有优越的吸能性, 能够提高防冲液压支架的安全性。Abstract: In order to increase the energy absorption of the anti-impact hydraulic support and improve its safety, a lattice energy-absorbing device was designed. The specific energy absorption and unit mass support force of three typical lattice cells were studied with the finite element simulation. The pyramid structure was determined to be the best topology of the lattice cells. The three-factor and five-level orthogonal experiment was used to analyze the influence of their body height, body inclination width and body diameter on energy absorption and support force and to determine the best body structural parameters. The simulation analysis shows that the total energy absorption of the pyramid lattice energy absorbing device with the best structural parameters is 1 470 kJ and that its support force is 4 699.76 kN. The support force changes relatively smoothly. It proves that the lattice energy-absorbing device with the pyramid structure has superior energy absorption and can improve the safety of the anti-impact hydraulic support.

-

Key words:

- anti-impact hydraulic support /

- safety /

- lattice structure /

- orthogonal test

-

表 1 胞体分析因素

因素 水平1 水平2 水平3 水平4 水平5 h/mm 10 30 50 70 90 a/mm 10 20 30 40 50 d/mm 4 5 6 7 8 表 2 正交实验样本及结果

序号 h/mm a/mm d/mm 吸能/kJ 支撑力/kN 1 5 1 2 896.8 26 116.0 2 3 3 5 189.1 4 114.2 3 1 2 4 137.6 4 330.1 4 4 2 1 233.6 3 599.4 5 5 2 5 751.0 18 548.5 6 4 1 3 960.0 26 212.4 7 3 1 4 766.7 28 276.0 8 5 4 1 261.3 1 262.3 9 3 4 3 78.5 1 488.3 10 3 5 1 145.7 1 287.7 11 1 4 5 100.6 9 913.8 12 4 4 2 87.9 1 607.4 13 1 5 3 38.5 1 560.6 14 2 5 2 12.4 508.5 15 4 5 5 163.1 2 632.2 16 4 3 4 267.3 4 525.1 17 5 3 3 217.3 4 598.8 18 2 4 4 106.6 1 474.9 19 2 3 1 111.1 514.1 20 5 5 4 226.8 3 259.7 21 2 1 5 496.3 28 670.9 22 1 3 2 14.8 321.8 23 1 1 1 152.6 3 617.1 24 2 2 3 197.4 3 040.1 25 3 2 2 293.8 5 027.3 表 3 吸能大小的影响极差

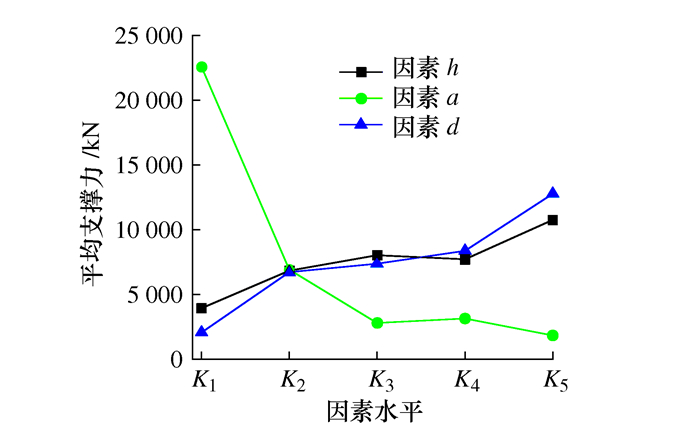

因素h 因素a 因素d K1 88.82 654.48 180.86 K2 184.76 322.68 261.14 K3 294.76 159.92 298.34 K4 342.38 126.98 301.00 K5 470.64 117.30 340.02 极差R 381.82 537.18 159.16 表 4 支撑力的影响极差

因素h 因素a 因素d K1 3 948.68 22 578.48 2 056.12 K2 6 841.70 6 909.08 6 716.20 K3 8 038.70 2 814.80 7 380.04 K4 7 715.30 3 149.34 8 373.16 K5 10 757.06 1 849.74 12 775.92 极差R 6 808.38 20 728.74 10 719.80 表 5 候选方案

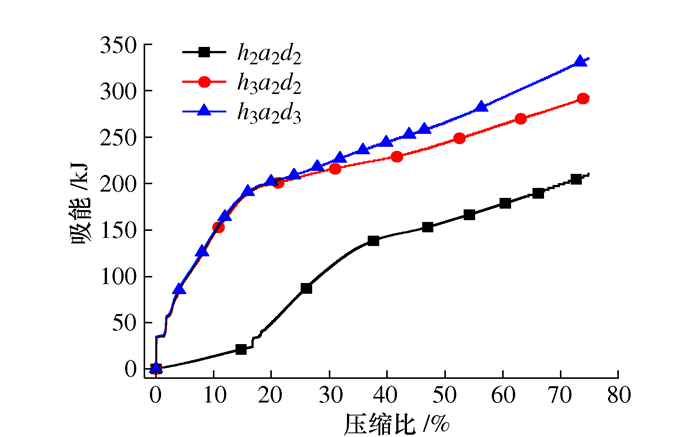

方案 因素h 因素a 因素d 1(h2a2d2) 30 20 5 2(h3a2d2) 50 20 5 3(h3a2d3) 50 20 6 -

[1] 潘一山, 肖永惠, 李国臻. 巷道防冲液压支架研究及应用[J]. 煤炭学报, 2020, 45(1): 90-99(in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202001010.htmPAN Y S, XIAO Y H, LI G Z. Roadway hydraulic support for rockburst prevention in coal mine and its application[J]. Journal of China Coal Society, 2020, 45(1): 90-99 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202001010.htm [2] 马箫, 潘一山, 张建卓, 等. 防冲支架的核心吸能构件设计与吸能性能研究[J]. 煤炭学报, 2018, 43(4): 1171-1178 https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201804047.htmMA X, PAN Y S, ZHANG J Z, et al. Design and performance research on core energy absorption component of anti-impact support[J]. Journal of China Coal Society, 2018, 43(4): 1171-1178 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201804047.htm [3] 潘一山, 肖永惠, 李忠华, 等. 冲击地压矿井巷道支护理论研究及应用[J]. 煤炭学报, 2014, 39(2): 222-228 https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201402003.htmPAN Y S, XIAO Y H, LI Z H, et al. Study of tunnel support theory of rock burst in coal mine and its application[J]. Journal of China Coal Society, 2014, 39(2): 222-228 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201402003.htm [4] 张建卓, 刘欢, 王洁. 直纹管外翻式构件设计与吸能特性研究[J]. 振动与冲击, 2020, 39(9): 49-56 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202009008.htmZHANG J Z, LIU H, WANG J. Design and energy-absorbing properties of the everting components of straight corrugated tubes[J]. Journal of Vibration and Shock, 2020, 39(9): 49-56 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202009008.htm [5] 董双勇, 褚晓威. 矿用锚杆吸能防冲支护构件的设计与分析[J]. 煤矿机械, 2020, 41(11): 62-64 https://www.cnki.com.cn/Article/CJFDTOTAL-MKJX202011021.htmDONG S Y, CHU X W. Design and analysis of energy absorption and rock burst prevention support component for mine bolt[J]. Coal Mine Machinery, 2020, 41(11): 62-64 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MKJX202011021.htm [6] 付玉凯, 鞠文君, 吴拥政, 等. 深部回采巷道锚杆(索)防冲吸能机理与实践[J]. 煤炭学报, 2020, 45(S2): 609-617 https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2020S2008.htmFU Y K, JU W J, WU Y Z, et al. Mechanism and practice of energy absorption and anti-impact of bolt (cable) in deep mining roadway[J]. Journal of China Coal Society, 2020, 45(S2): 609-617 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2020S2008.htm [7] 王春华, 牛慧超, 安达, 等. 防冲液压支架变梯度薄壁吸能构件研究[J]. 科学技术与工程, 2020, 20(9): 3546-3551WANG C H, NIU H C, AN D, et al. Research on variable gradient thin-walled energy absorbing component of scour-proof hydraulic support[J]. Science Technology and Engineering, 2020, 20(9): 3546-3551 (in Chinese) [8] 许琦, 阎军, 蒋存存, 等. 航天器点阵夹层圆柱壳构型多学科优化设计[J]. 载人航天, 2020, 26(2): 152-158 https://www.cnki.com.cn/Article/CJFDTOTAL-ZRHT202002003.htmXU Q, YAN J, JIANG C C, et al. Multi-disciplinary optimization design of multi-layer lattice sandwich cylindrical shell in spacecraft[J]. Manned Spaceflight, 2020, 26(2): 152-158 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZRHT202002003.htm [9] 丁莉, 满孝颖, 解维华, 等. 双锥构型三维点阵材料压缩特性[J]. 上海大学学报(自然科学版), 2020, 26(1): 76-84 https://www.cnki.com.cn/Article/CJFDTOTAL-SDXZ202001007.htmDING L, MAN X Y, XIE W H, et al. Compression properties of 3D dual-pyramid lattice materials[J]. Journal of Shanghai University (Natural Science Edition), 2020, 26(1): 76-84 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SDXZ202001007.htm [10] 廖中源, 王英俊, 王书亭. 基于拓扑优化的变密度点阵结构体优化设计方法[J]. 机械工程学报, 2019, 55(8): 65-72 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201908008.htmLIAO Z Y, WANG Y J, WANG S T. Graded-density lattice structure optimization design based on topology optimization[J]. Journal of Mechanical Engineering, 2019, 55(8): 65-72 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201908008.htm [11] CHEN X Y, MOUGHAMES J, JI Q X, et al. Optimal isotropic, reusable truss lattice material with near-zero Poisson's ratio[J]. Extreme Mechanics Letters, 2020, 41: 101048 [12] JIN N, YAN Z Y, WANG Y W, et al. Effects of heat treatment on microstructure and mechanical properties of selective laser melted Ti-6Al-4V lattice materials[J]. International Journal of Mechanical Sciences, 2021, 190: 106042 [13] 亓昌, 郝鹏程, 舒剑, 等. 金字塔型点阵材料夹芯板抗爆性能仿真与优化[J]. 振动与冲击, 2019, 38(16): 245-252 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201916035.htmQI C, HAO P C, SHU J, et al. Simulation and optimization for blast-resistant performances of pyramidal lattice cored sandwich panels[J]. Journal of Vibration and Shock, 2019, 38(16): 245-252 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201916035.htm [14] 刘培生. 多孔金属格子材料(点阵材料)的制造方法[J]. 稀有金属材料与工程, 2007, 36(S3): 535-538 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2007S3129.htmLIU P S. Preparation methods for porous metallic lattice materials[J]. Rare Metal Materials and Engineering, 2007, 36(S3): 535-538 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2007S3129.htm [15] 戴向胜, 马建敏. 冲击块与金属圆柱壳相互作用的缓冲吸能分析[J]. 振动工程学报, 2013, 26(3): 429-435 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC201303018.htmDAI X S, MA J M. Analysis of buffer effect and energy absorption between impact object and cylindrical metal shell[J]. Journal of Vibration Engineering, 2013, 26(3): 429-435 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC201303018.htm -

下载:

下载: