Analysis of Flow Field Characteristics of Multi-nozzle Jet Ventilation

-

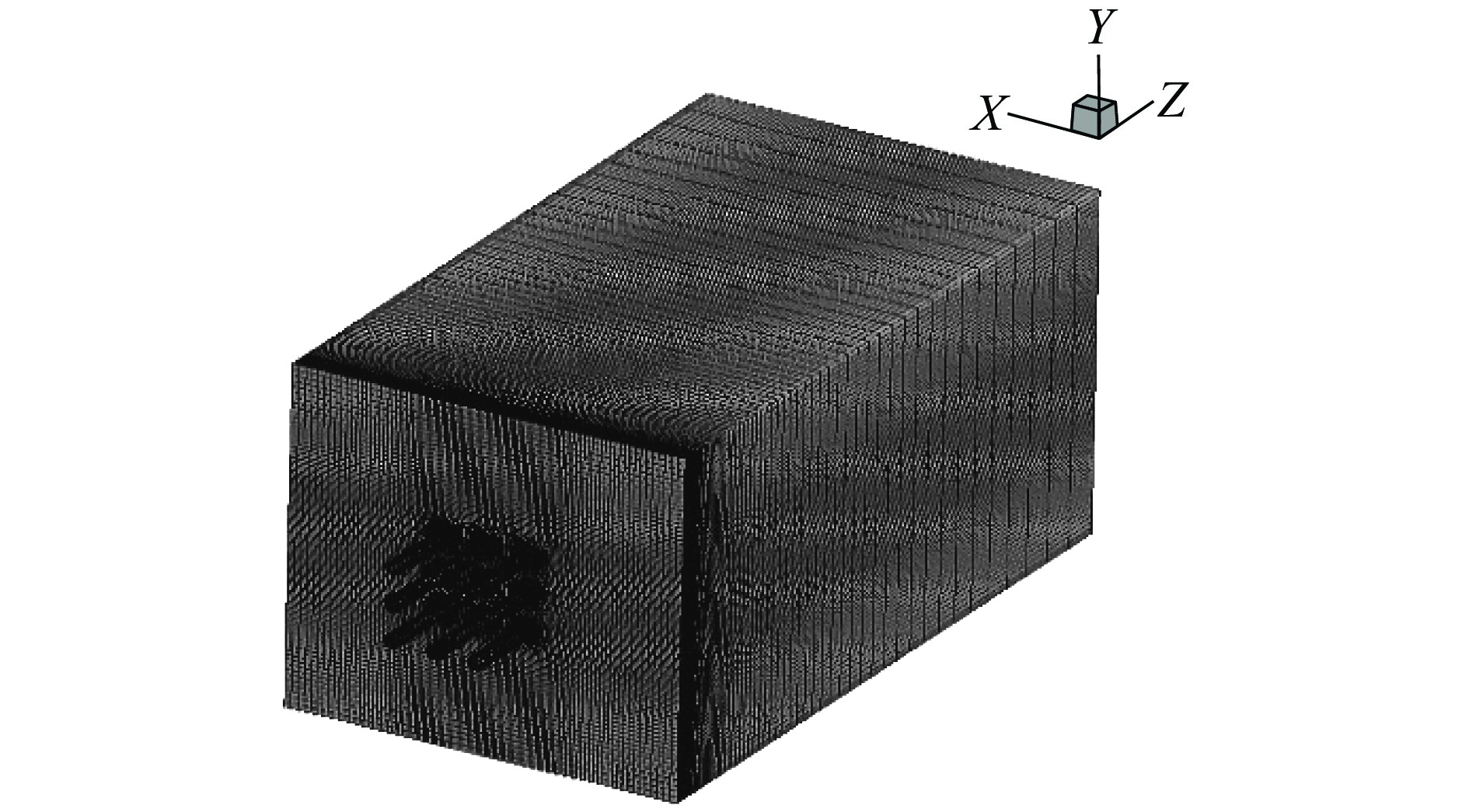

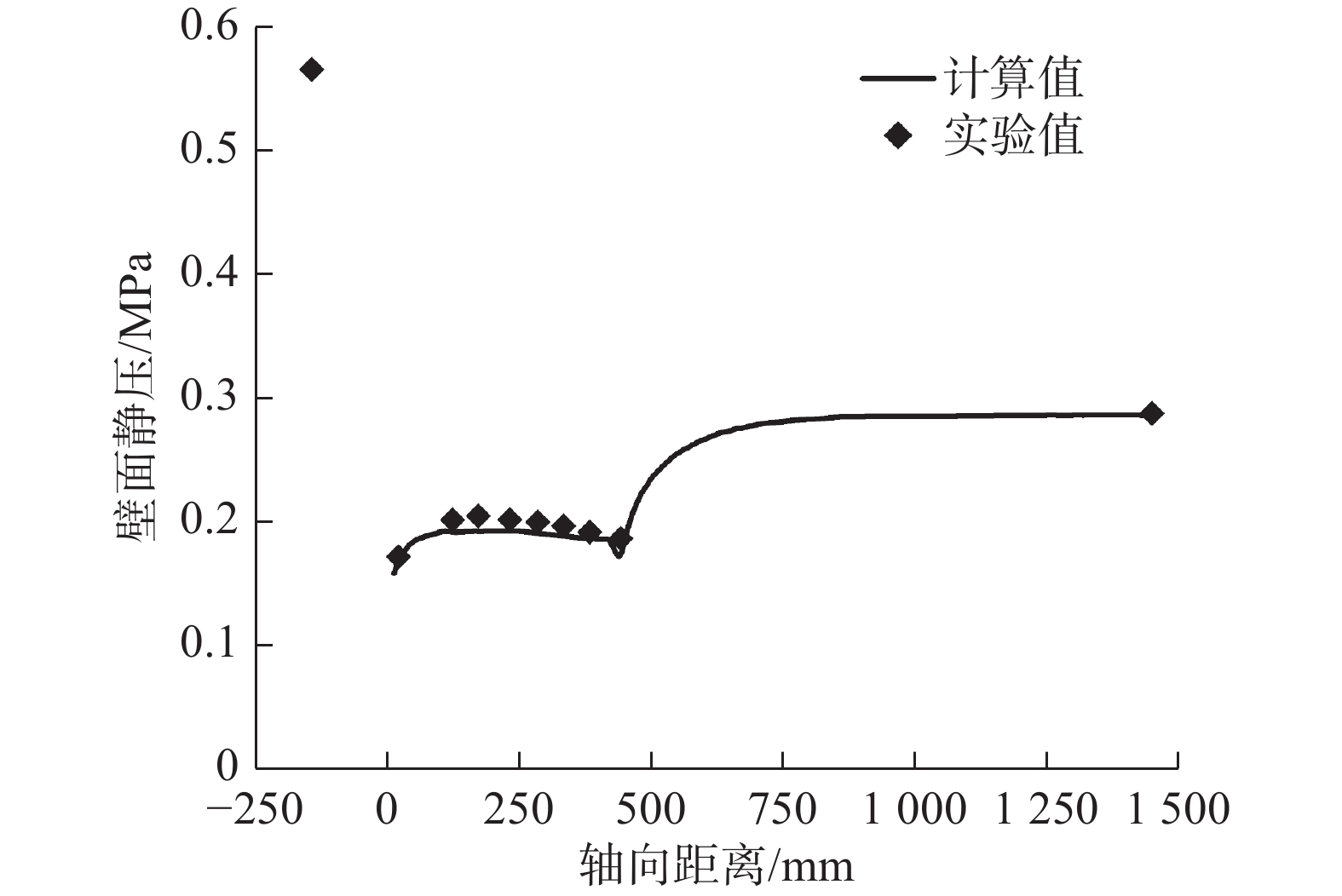

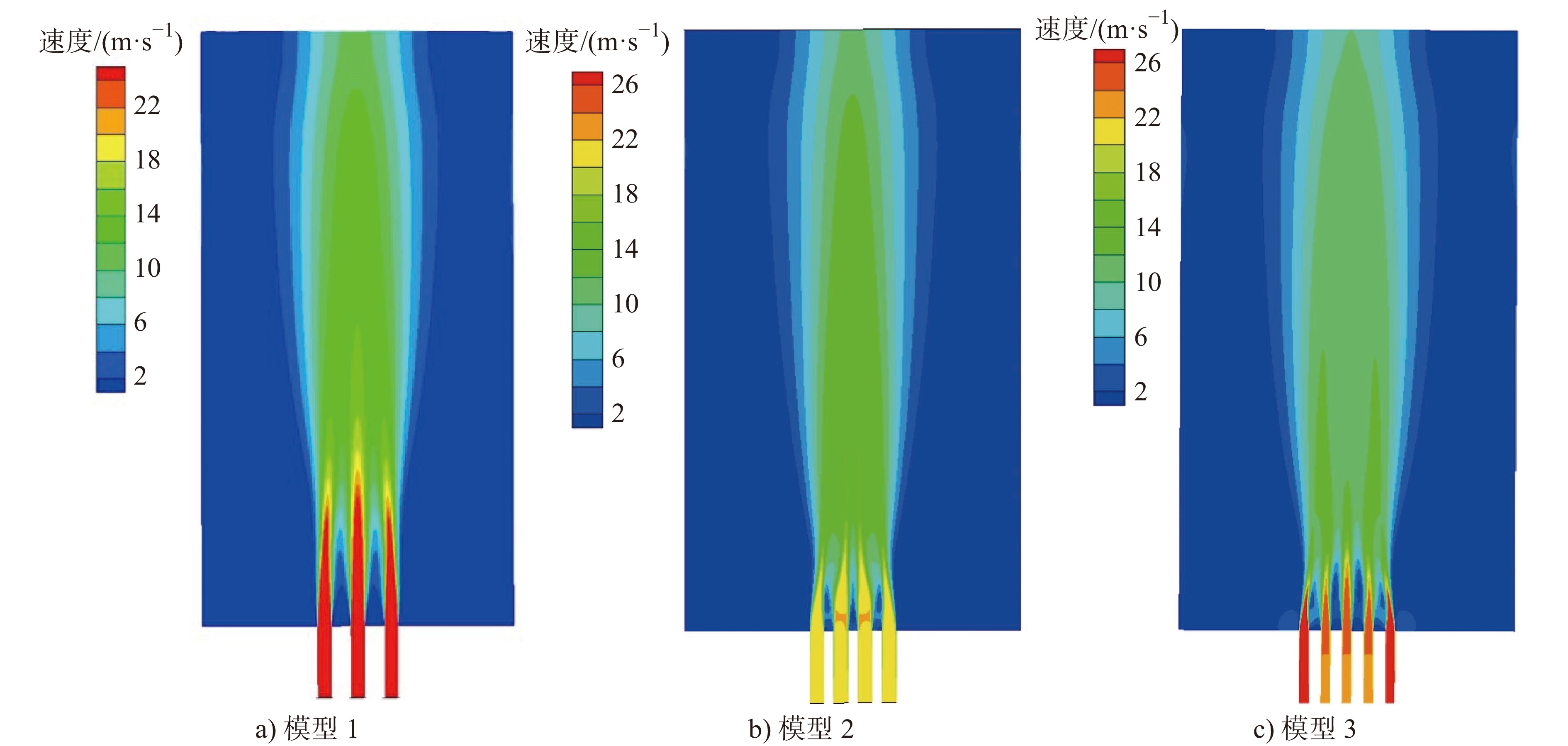

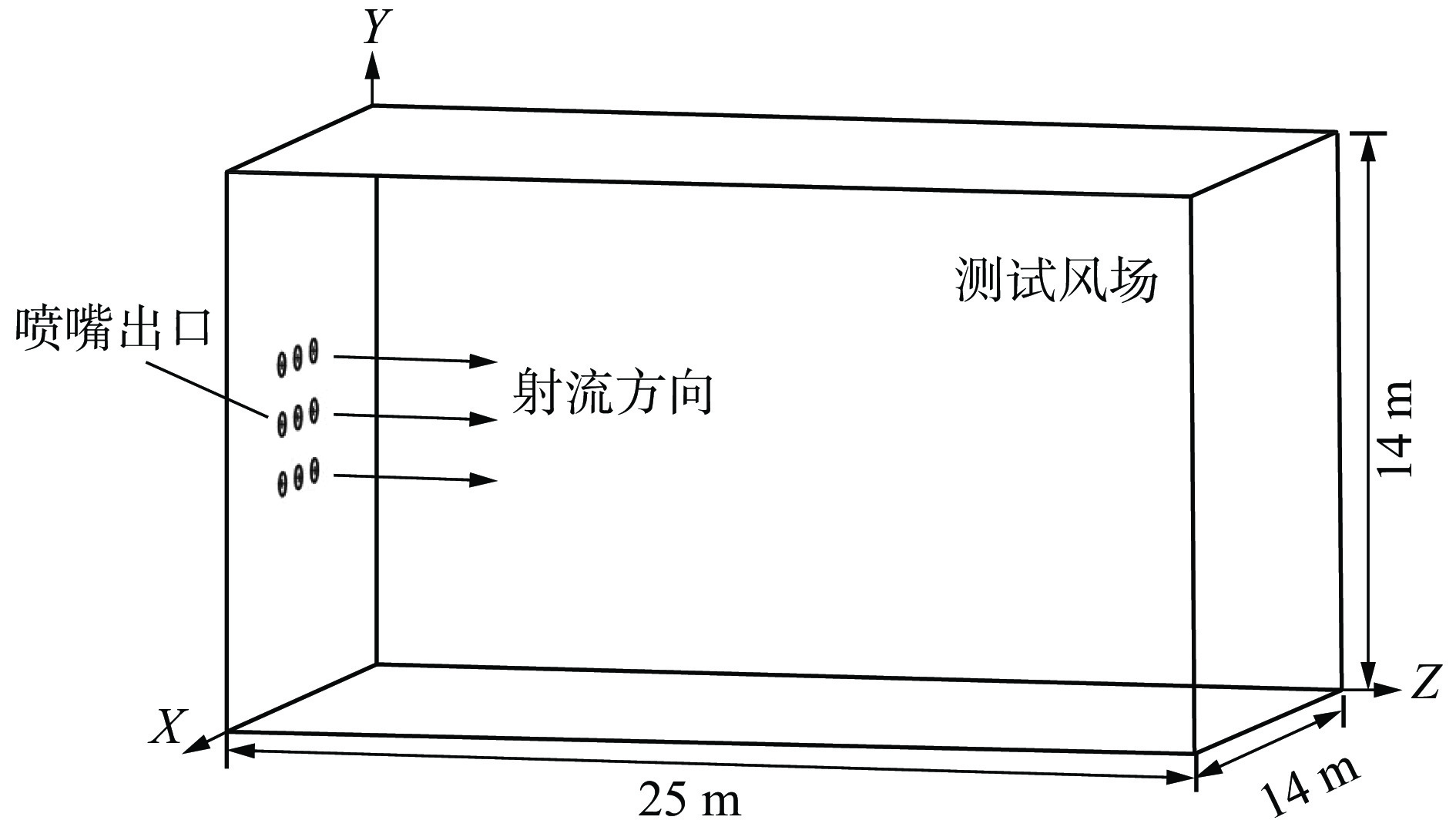

摘要: 为了分析多孔射流风机作用下风场的流场特性,文中采用CFD方法,对多孔射流式风场模型内部流场进行了数值模拟,对比分析了不同喷嘴数量及排布方式对流场性能的影响,并引入涡动力学理论,分析了流场内涡结构的分布发展规律及其对流体掺混的影响。结果表明:喷嘴的数量及排布方式对流场性能有显著影响,外围喷嘴会对中心喷嘴的流动起到限制作用;流向涡对流体掺混效果的作用比展向涡大,在涡量一定的情况下,流向涡尺度越大、衰减越快,流体间的混合效果越好,流场稳定性越高。流场内速度及涡动力学分布表明,流场稳定性随着喷嘴数量的增加而显著提高,因此在保证经济性的前提下应尽量采用数量多的喷嘴排布方式。Abstract: To analyze the flow field characteristics of the wind field under the action of the porous jet fan, the CFD method is used to simulate the internal flow field of the porous jet wind field model, and the effects of the number and arrangement of nozzles on the flow field performance are compared and analyzed. The theory of vortex dynamics is introduced to analyze the distribution and development of vortex structure in the flow field and its influence on fluid mixing effect. The simulation results show that the arrangement of nozzles has a significant impact on the flow field performance, and the peripheral nozzles will restrict the flow of the central nozzle; the streamwise vortex has a greater effect on the fluid mixing effect than the spanwise vortex. In the case of a constant vortex, a larger flow vortex scale and faster attenuation is advantageous to the flow field stability. The velocity and vortex dynamics distribution in the flow field show that the stability of the flow field increases significantly with the increase of the number of nozzles. Therefore, the number of nozzle arrangements should be used as much as possible on the premise of ensuring economy.

-

Key words:

- multi-nozzle jet /

- wind field /

- CFD /

- flow characteristics /

- vortex dynamics

-

表 1 喷嘴排布参数

模型 喷嘴排布

方式喷嘴直径

D/m喷嘴间距

L/m1 3 × 3 0.6 1.5 2 4 × 4 0.6 1.5 3 5 × 5 0.4 0.9 表 2 喷嘴速度设置

模型 外圈喷嘴速度

${v_1} /( {{\rm{m}} \cdot {{\rm{s}}^{ - 1} } } )$内圈喷嘴速度

${v_2}/( {{\rm{m}} \cdot {{\rm{s}}^{ - 1}}} ) $1 30 30 2 21 21 3 28 23 -

[1] 师虹. 基于CFD的特长公路隧道通风排烟数值模拟研究[D]. 西安: 长安大学, 2019SHI H. Numerical simulation of ventilation and smoke exhaust of special long highway tunnel based on CFD[D]. Xi′an: Chang′an University, 2019. (in Chinese) [2] 李炎锋, 崔彦强, 常琳, 等. 地下车库射流诱导通风的数值模拟研究[J]. 广西大学学报(自然科学版), 2017, 42(1): 365-370. doi: 10.13624/j.cnki.issn.1001-7445.2017.0365LI Y F, CUI Y Q, CHANG L, et al. Numerical simulation of jet ventilation for underground garage[J]. Journal of Guangxi University (Natural Science Edition), 2017, 42(1): 365-370. (in Chinese) doi: 10.13624/j.cnki.issn.1001-7445.2017.0365 [3] 曹学明, 张忠泽. 公路隧道纵向射流通风数值模拟与分析[J]. 制冷与空调, 2011, 25(6): 558-561.CAO X M, ZHANG Z Z. The numerical simulation and analysis of road tunnel longitudinal ventilation[J]. Refrigeration and Air Conditioning, 2011, 25(6): 558-561. (in Chinese) [4] 胡康, 邵雪. 基于CFD对公路隧道纵向射流通风系统的研究[J]. 南方能源建设, 2020, 7(S2): 131-136. doi: 10.16516/j.gedi.issn2095-8676.2020.S2.021HU K, SHAO X. Research on longitudinal jet ventilation system of highway tunnel based on CFD[J]. Southern Energy Construction, 2020, 7(S2): 131-136. (in Chinese) doi: 10.16516/j.gedi.issn2095-8676.2020.S2.021 [5] RAIZNER M, RINSKY V, GROSSMAN G, et al. Heat transfer and flow field measurements of a pulsating round jet impinging on a flat heated surface[J]. International Journal of Heat and Fluid Flow, 2019, 77: 278-287. doi: 10.1016/j.ijheatfluidflow.2019.04.010 [6] 朱伶枫, 张延玲, 朱荣, 等. 超音速射流流场湍流模型适应性研究[J]. 太原理工大学学报, 2015, 46(1): 49-54. doi: 10.16355/j.cnki.issn1007-9432tyut.2015.01.010ZHU L F, ZHANG Y L, ZHU R, et al. Study on adaptability of supersonic jet flow turbulence model[J]. Journal of Taiyuan University of Technology, 2015, 46(1): 49-54. (in Chinese) doi: 10.16355/j.cnki.issn1007-9432tyut.2015.01.010 [7] TANI H, TERAMOTO S, OKAMOTO K. High-speed observations of cryogenic single and coaxial jets under subcritical and transcritical conditions[J]. Experiments in Fluids, 2015, 56(4): 85. doi: 10.1007/s00348-015-1956-0 [8] NAQAVI I Z, TUCKER P G, LIU Y. Large-eddy simulation of the interaction of wall jets with external stream[J]. International Journal of Heat and Fluid Flow, 2014, 50: 431-444. doi: 10.1016/j.ijheatfluidflow.2014.10.014 [9] 龙新平, 姚鑫, 杨雪龙. 多孔喷嘴射流泵流动模拟与涡结构分析[J]. 排灌机械工程学报, 2012, 30(2): 136-140. doi: 10.3969/j.issn.1674-8530.2012.02.003LONG X P, YAO X, YANG X L. Flow simulation and vortex structure analysis of multi-nozzle jet pumps[J]. Journal of Drainage and Irrigation Machinery Engineering, 2012, 30(2): 136-140. (in Chinese) doi: 10.3969/j.issn.1674-8530.2012.02.003 [10] 梁博健, 高殿荣. 高压扇形喷嘴结构参数的优化[J]. 排灌机械工程学报, 2020, 38(1): 69-75. doi: 10.3969/j.issn.1674-8530.18.0091LIANG B J, GAO D R. Optimization of structural parameters of fan-shaped high-pressure nozzle[J]. Journal of Drainage and Irrigation Machinery Engineering, 2020, 38(1): 69-75. (in Chinese) doi: 10.3969/j.issn.1674-8530.18.0091 [11] 金煜, 冷先银, 陈广平, 等. 内/外交叉孔喷嘴内部和近场流动特性的试验[J]. 内燃机工程, 2018, 39(2): 35-42. doi: 10.13949/j.cnki.nrjgc.2018.02.006JIN Y, LENG X Y, CHEN G P, et al. An experimental study on the internal and near-field flow characteristics of internal/external intersecting-hole nozzles[J]. Chinese Internal Combustion Engine Engineering, 2018, 39(2): 35-42. (in Chinese) doi: 10.13949/j.cnki.nrjgc.2018.02.006 [12] 张福波, 张永臣, 杨丽娟. 圆形喷嘴内部结构对射流冲击换热性能的影响[J]. 东北大学学报(自然科学版), 2018, 39(9): 1257-1261. doi: 10.12068/j.issn.1005-3026.2018.09.009ZHANG F B, ZHANG Y C, YANG L J. Influence of internal structure of round jet nozzle on heat transfer performance[J]. Journal of Northeastern University (Natural Science), 2018, 39(9): 1257-1261. (in Chinese) doi: 10.12068/j.issn.1005-3026.2018.09.009 [13] 王卓. 静水条件下倾斜射流的Realizable k-ε和RNG k-ε数值模拟研究[J]. 人民珠江, 2017, 38(5): 53-57.WANG Z. Numerical simulation of realizable k-ε and RNG k-ε for inclined jets in under hydrostatic conditions[J]. Pearl River, 2017, 38(5): 53-57. (in Chinese) [14] 芦绮玲, 陈刚. 多孔紊动射流的数值模拟与实验研究进展[J]. 水科学进展, 2008, 19(1): 137-146. doi: 10.3321/j.issn:1001-6791.2008.01.023LU Q L, CHEN G. Development in numerical and experimental study of the multiple jets[J]. Advances In Water Science, 2008, 19(1): 137-146. (in Chinese) doi: 10.3321/j.issn:1001-6791.2008.01.023 [15] 李少华, 袁斌, 刘利献, 等. 多孔横向紊动射流涡量场的数值分析[J]. 中国电机工程学报, 2007, 27(23): 100-104. doi: 10.3321/j.issn:0258-8013.2007.23.019LI S H, YUAN B, LIU L X, et al. Numerical investigation on the vortices of multiple turbulent jet in crossflow[J]. Proceedings of the CSEE, 2007, 27(23): 100-104. (in Chinese) doi: 10.3321/j.issn:0258-8013.2007.23.019 [16] YANG X, LONG X, YAO X. Numerical investigation on the mixing process in a steam ejector with different nozzle structures[J]. International Journal of Thermal Sciences, 2012, 56: 95-106. doi: 10.1016/j.ijthermalsci.2012.01.021 [17] NARABAYASHI T, YAMAZAKI Y, KOBAYASHI H, et al. Flow analysis for single and multi-nozzle jet pump[J]. JSME International Journal Series B Fluids and Thermal Engineering, 2006, 49(4): 933-940. doi: 10.1299/jsmeb.49.933 [18] HU H, KOBAYASHI T. Vortex structures downstream a lobed nozzle/mixer[J]. Journal of Aerospace Power, 2008, 23(7): 1266-1278. -

下载:

下载: