Robust Amplitude Exponential Adaptive Method for Spectral Amplitude Modulation

-

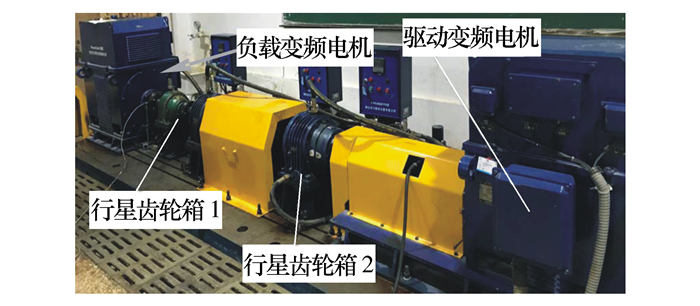

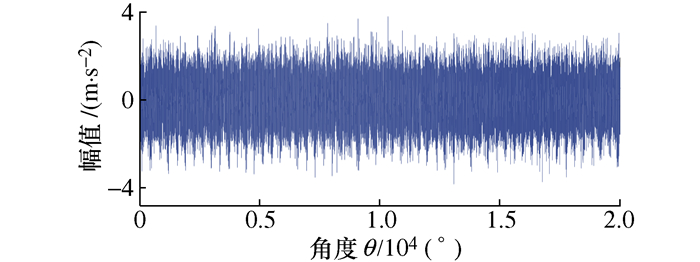

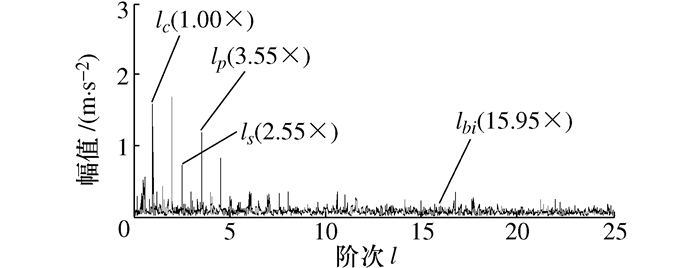

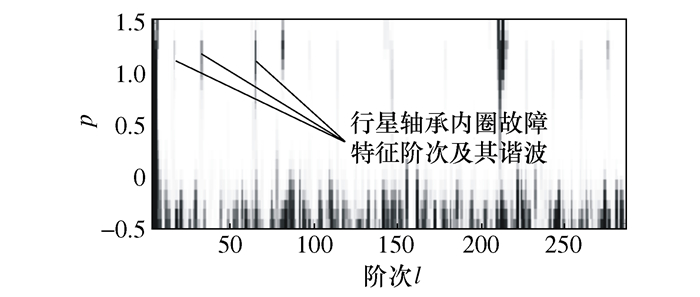

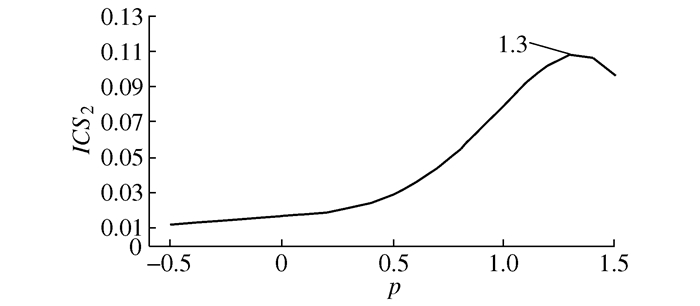

摘要: 近期提出的谱幅值调制(SAM)法可通过调节幅值指数适应不同故障信号的特征提取,具有较好的应用前景。但该方法目前幅值指数的取值需人工判断,尚无法用其实现对故障特征的自动优化提取,且当故障特征受到复杂干扰时,通过人工选择较难选取较佳的幅值指数。为此,本文研究提出了一种鲁棒性幅值指数自适应谱幅值调制法。该方法首先利用角域重采样将信号转换到角域,再通过多点最优最小熵解卷积(MOMEDA)对故障弱冲击特征进行增强,最后利用2阶循环平稳指标(ICS2)自适应选取SAM中的倒谱幅值指数,以该优化幅值指数计算倒谱信号,实现故障特征的自动提取。在行星轴承内圈故障特征提取上进行了验证研究,实验结果表明,本文所提方法能够实现复杂干扰下行星轴承内圈故障特征的自适应提取。Abstract: The spectrum amplitude modulation (SAM) method, which was proposed recently, can be used to do the feature extraction of different fault signals by adjusting the exponential of amplitude adaptively, and it has a quite good practical perspective. However, the exponential of amplitude of this method still needs to be judged manually, which leads to the result that it can not be used to extract the fault features automatically. Moreover, when the fault features are interfered by complex disturbances, it is difficult to select the optimal exponential of amplitude manually. Therefore, a robust amplitude exponential adaptive spectral amplitude modulation method is proposed in this paper. Firstly, the signal is converted to angular domain by angle domain resampling, and then the shock characteristics generated by the faulty planet bearing are enhanced by the multipoint optimal minimum entropy deconvolution adjusted (MOMEDA). Finally, the exponential of cepstrum amplitude in SAM is adaptively selected with ICS2 (indicator of second order cyclostationary). The cepstrum signal is calculated by the optimal exponential of amplitude, in this way, the problem that the SAM method cannot automatically extract fault features is solved. The fault feature extraction of inner race of planetary bearing is verified. Experimental results show that the proposed method can adaptively extract fault features of inner race of planetary bearing under complex interference.

-

表 1 行星轴承参数

滚子数n 滚子直径d/mm 节圆直径D/mm 接触角α/(°) 10 9 36 0 表 2 齿轮参数

齿轮 太阳轮 行星轮(3个) 齿圈 齿数 28 20 71 模数 2.25 2.25 2.25 变位系数 0.754 0.529 0.162 表 3 行星轴承内圈故障相关阶次

参数 数值 太阳轮绝对旋转阶次ls 2.53× 行星架旋转阶次lc 1.00× 行星轮绝对旋转阶次lp 3.55× 行星轮轴承内圈故障特征阶次lbi 15.95× 行星轮轮齿啮合阶次lm 71× -

[1] 李杰, 赵建民. 基于时域同步平均与分离技术的齿轮箱振动信号混沌特性验证[J]. 机械传动, 2018, 42(7): 162-167 https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201807033.htmLI J, ZHAO J M. Chaotic characteristic verification of gearbox vibration signal based on the time synchronous averaging and separation technology[J]. Journal of Mechanical Transmission, 2018, 42(7): 162-167 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201807033.htm [2] 高佳豪, 郭瑜, 伍星. 基于SANC和一维卷积神经网络的齿轮箱轴承故障诊断[J]. 振动与冲击, 2020, 39(19): 204-209+257 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202019031.htmGAO J H, GUO Y, WU X. Gearbox bearing fault diagnosis based on SANC and 1-D CNN[J]. Journal of Vibration and Shock, 2020, 39(19): 204-209+257 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202019031.htm [3] ABBOUD D, ANTONI J, SIEG-ZIEBA S, et al. Deterministic-random separation in nonstationary regime[J]. Journal of Sound and Vibration, 2016, 362: 305-326 doi: 10.1016/j.jsv.2015.09.029 [4] PEETERS C, GUILLAUME P, HELSEN J. A comparison of cepstral editing methods as signal pre-processing techniques for vibration-based bearing fault detection[J]. Mechanical Systems and Signal Processing, 2017, 91(3): 354-381 [5] 张晓飞, 胡茑庆, 胡雷, 等. 基于倒谱预白化和随机共振的轴承故障增强检测[J]. 机械工程学报, 2012, 48(23): 83-89 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201223014.htmZHANG X F, HU N Q, HU L, et al. Enhanced detection of bearing faults based on signal cepstrum pre-whitening and stochastic resonance[J]. Journal of Mechanical Engineering, 2012, 48(23): 83-89 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201223014.htm [6] 邓飞跃, 唐贵基, 何玉灵. 基于倒谱预白化和形态学自互补Top-Hat变换的滚动轴承故障特征提取[J]. 振动与冲击, 2015, 34(15): 77-81+149 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201515016.htmDENG F Y, TANG G J, HE Y L. Fault feature extraction for rolling element bearings based on cepstrum pre-whitening and morphology self-complementary Top-Hat transformation[J]. Journal of Vibration and Shock, 2015, 34(15): 77-81+149 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201515016.htm [7] IBARRA-ZARATE D, TAMAYO-PAZOS O, VALLEJO-GUEVARA A. Bearing fault diagnosis in rotating machinery based on cepstrum pre-whitening of vibration and acoustic emission[J]. The International Journal of Advanced Manufacturing Technology, 2019, 104(9-12): 4155-4168 doi: 10.1007/s00170-019-04171-6 [8] MOSHREFZADEH A, FASANA A, ANTONI J. The spectral amplitude modulation: a nonlinear filtering process for diagnosis of rolling element bearings[J]. Mechanical Systems and Signal Processing, 2019, 132: 253-276 [9] MCDONALD G L, ZHAO Q. Multipoint optimal minimum entropy deconvolution and convolution fix: application to vibration fault detection[J]. Mechanical Systems and Signal Processing, 2017, 82: 461-477 [10] SMITH W A, RANDALL R B, DE CHASTEIGNER DU MÉE X, et al. Use of cyclostationary properties to diagnose planet bearing faults in variable speed conditions[C]//Proceedings of the Tenth DST Group International Conference on Health and Usage Monitoring Systems. Melbourne, 2017 [11] 赵修平, 齐嘉兴, 崔伟成, 等. MOMEDA结合数学形态滤波的齿轮故障特征提取[J]. 机械科学与技术, 2020, 39(2): 247-252 doi: 10.13433/j.cnki.1003-8728.20190122ZHAO X P, QI J X, CUI W C, et al. Gear fault feature extraction applying MOMEDA and mathematical morphology filtering[J]. Mechanical Science and Technology for Aerospace Engineering, 2020, 39(2): 247-252 (in Chinese) doi: 10.13433/j.cnki.1003-8728.20190122 [12] 孔运, 王天杨, 褚福磊. 自适应TQWT滤波器算法及其在冲击特征提取中的应用[J]. 振动与冲击, 2019, 38(11): 9-16+23 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201911003.htmKONG Y, WANG T Y, CHU F L. Adaptive TQWT filter algorithm and its application in impact feature extraction[J]. Journal of Vibration and Shock, 2019, 38(11): 9-16+23 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201911003.htm [13] MCDONALD G L, ZHAO Q, ZUO M J. Maximum correlated kurtosis deconvolution and application on gear tooth chip fault detection[J]. Mechanical Systems and Signal Processing, 2012, 33: 237-255 [14] RANDALL R B, ANTONI J. Rolling element bearing diagnostics-A tutorial[J]. Mechanical Systems and Signal Processing, 2011, 25(2): 485-520 [15] 武超, 孙虎儿, 梁晓华. 基于MOMEDA和包络谱的齿轮微弱故障特征提取[J]. 机械传动, 2018, 42(3): 164-168 https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201803034.htmWU C, SUN H E, LIANG X H. Feature extraction of weak fault for gear based on MOMEDA and envelope spectrum[J]. Journal of Mechanical Transmission, 2018, 42(3): 164-168 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201803034.htm -

下载:

下载: