Fault Diagnosis Method of Rolling Bearing Combining Time-frequency Analysis with Deep Learning

-

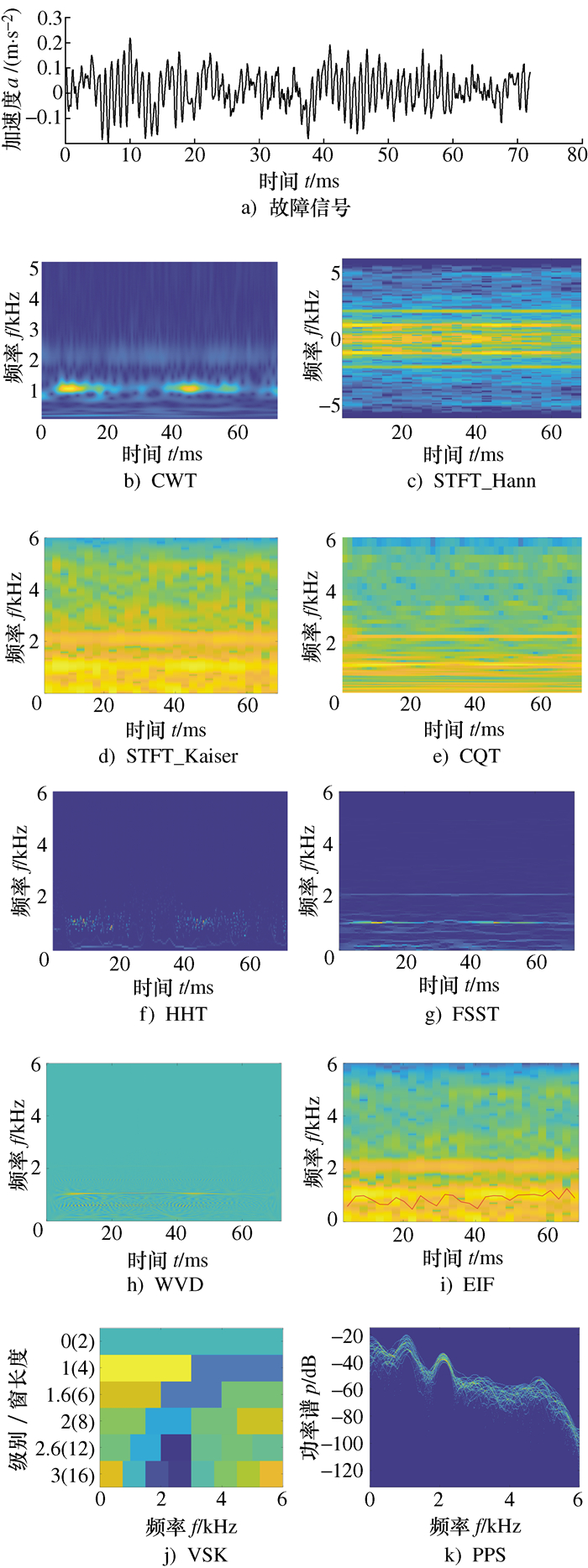

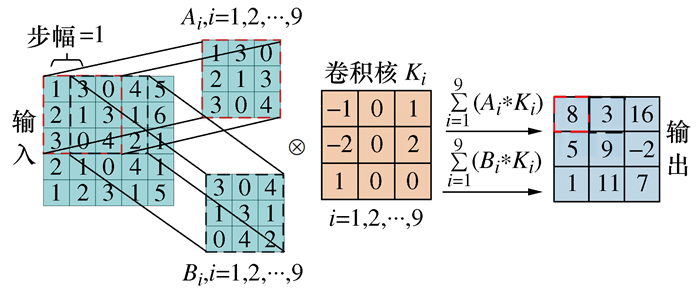

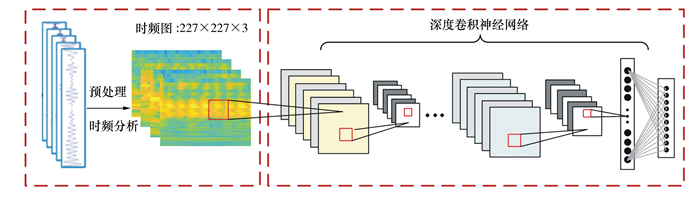

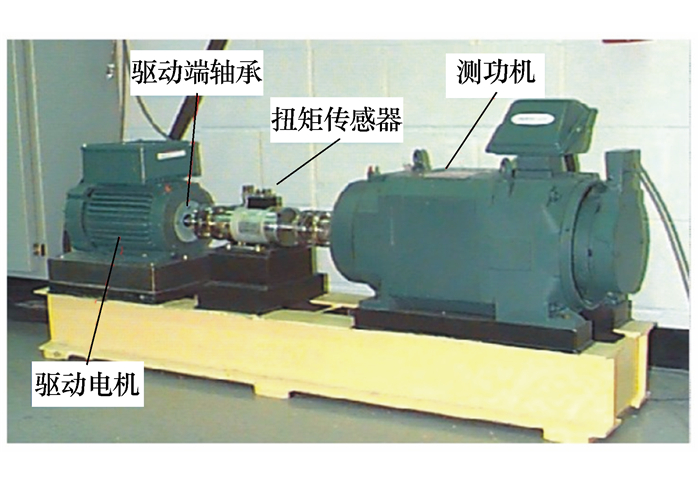

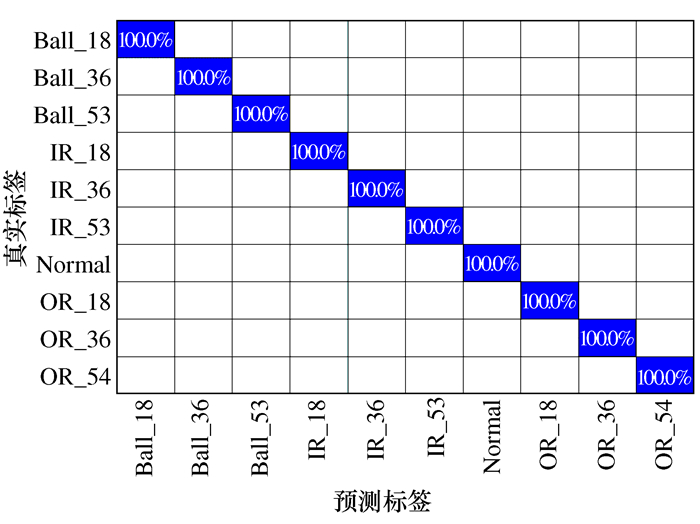

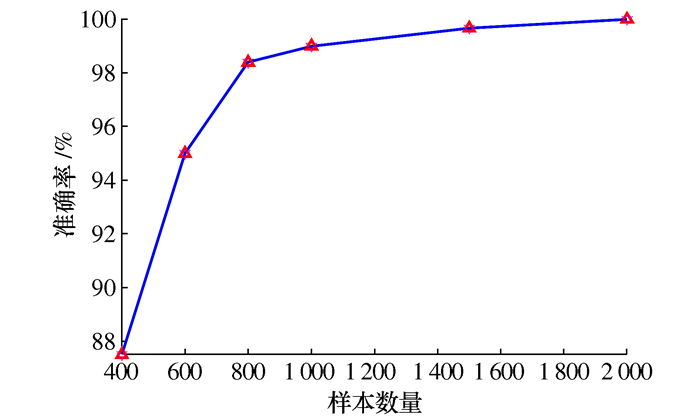

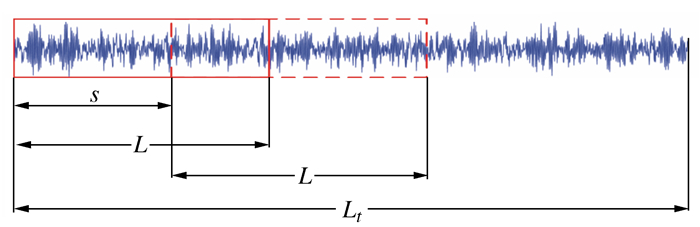

摘要: 滚动轴承大量使用在旋转机械中, 轴承的工况严重影响着机械设备的正常运行。为了提高轴承故障的诊断精度, 本文提出了一种时频分析和深度学习相结合的滚动轴承诊断方法。首先, 分析了十种不同时频分析方法; 其次, 建立了深度学习的滚动轴承故障诊断模型, 并利用迁移学习克服训练样本数量少的问题, 通过对比分析, 常数Q变换(Constant Q transform, CQT)的准确率可达100%;最后, 利用实验数据对所提方法的有效性和可靠性进行验证, 分别评估了在不同负载和噪声情况下的识别精度, 并与文献中的方法对比, 证明所提方法在不同工作环境条件下都有较好的鲁棒性和较高的识别精度。Abstract: Rolling bearings are widely used in rotating machinery, and the working conditions of the bearings seriously affect the normal operation of mechanical equipment. In order to improve the accuracy of bearing fault diagnosis, a new fault diagnosis method of rolling bearing combining time-frequency analysis with deep learning is proposed in this paper. Firstly, ten different time-frequency analysis methods are analyzed and compared. Then, the fault diagnosis model for rolling bearings using deep learning is established, and the transfer learning is applied to overcome the problem led by small number of training samples. By contrast, the accuracy of constant Q transform (CQT) can reach 100%. Finally, the effectiveness and reliability of the proposed method are verified via the experimental data. The recognition accuracies under different working loads and noise environment are evaluated respectively, and are compared to the results obtained by other methods in references. The results show that the proposed method has better robustness and higher recognition accuracy under different working environment conditions.

-

Key words:

- rolling bearing /

- fault diagnosis /

- time-frequency analysis /

- deep learning /

- transfer learning

-

表 1 采用的十种时频分析方法

序号 时频分析方法 简写 1 连续一维小波变换 CWT 2 采用Hann窗的短时傅里叶变换 STFT-Hann 3 采用Kaiser窗的短时傅里叶变换 STFT-Kaiser 4 常数Q变换 CQT 5 Hilbert-Huang变换 HHT 6 傅立叶同步压缩变换 FSST 7 Wigner-Ville分布 WVD 8 估计瞬时频率 EIF 9 可视化光谱峰度 VSK 10 持久功率谱 PPS 表 2 滚动轴承数据集描述

名称 正常 内圈故障 滚动体故障 外圈故障 缺损凹坑直径/mm 0 0.18 0.36 0.53 0.18 0.36 0.53 0.18 0.36 0.53 数据标签 Normal IR_18 IR_36 IR_53 Ball_18 Ball_36 Ball_53 OR_18 OR_36 OR_53 数据集A 训练集 160 160 160 160 160 160 160 160 160 160 测试集 40 40 40 40 40 40 40 40 40 40 数据集B 训练集 160 160 160 160 160 160 160 160 160 160 测试集 40 40 40 40 40 40 40 40 40 40 数据集C 训练集 160 160 160 160 160 160 160 160 160 160 测试集 40 40 40 40 40 40 40 40 40 40 数据集D 训练集 160 160 160 160 160 160 160 160 160 160 测试集 4 40 40 40 40 40 40 40 40 40 表 3 不同时频分析诊断结果

时频分析方法 准确率/% 时间/s CWT 99.83 1 171 STFT-Hann 99.50 4 796 STFT-Kaiser 99.50 3 445 CQT 100.00 1 608 HHT 88.50 1 062 FSST 99.75 1 444 WVD 98.50 145 EIF 99.40 3 881 VSK 84.00 1 820 PPS 99.75 2 120 表 4 针对负载适应性的数据设置

描述 源域数据 目标域数据 训练集B 测试集C 测试集D 数据设置 训练集C 测试集B 测试集D 训练集D 测试集B 测试集C -

[1] WANG Z J, ZHOU J, WANG J Y, et al. A novel fault diagnosis method of gearbox based on maximum kurtosis spectral entropy deconvolution[J]. IEEE Access, 2019, 7: 29520-29532 doi: 10.1109/ACCESS.2019.2900503 [2] 雷亚国, 杨彬, 杜兆钧, 等. 大数据下机械装备故障的深度迁移诊断方法[J]. 机械工程学报, 2019, 55(7): 1-8 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201907001.htmLEI Y G, YANG B, DU Z J, et al. Deep transfer diagnosis method for machinery in big data era[J]. Journal of Mechanical Engineering, 2019, 55(7): 1-8 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201907001.htm [3] ZHANG W, PENG G L, LI C H, et al. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals[J]. Sensors, 2017, 17(2): 425 doi: 10.3390/s17020425 [4] 孙国栋, 王俊豪, 徐昀, 等. CEEMD-WVD多尺度时频图像的滚动轴承故障诊断[J]. 机械科学与技术, 2020, 39(5): 688-694 doi: 10.13433/j.cnki.1003-8728.20190192SUN G D, WANG J H, XU Y, et al. Rolling bearing fault diagnosis based on CEEMD-WVD multi-scale time-frequency image[J]. Mechanical Science and Technology for Aerospace Engineering, 2020, 39(5): 688-694 (in Chinese) doi: 10.13433/j.cnki.1003-8728.20190192 [5] DENG J, XU X Z, ZHANG Z X, et al. Universum autoencoder-based domain adaptation for speech emotion recognition[J]. IEEE Signal Processing Letters, 2017, 24(4): 500-504 doi: 10.1109/LSP.2017.2672753 [6] WANG J Y, MO Z L, ZHANG H, et al. A deep learning method for bearing fault diagnosis based on time-frequency image[J]. IEEE Access, 2019, 7: 42373-42383 doi: 10.1109/ACCESS.2019.2907131 [7] SARAVANAN N, RAMACHANDRAN K I. Incipient gear box fault diagnosis using discrete wavelet transform (DWT) for feature extraction and classification using artificial neural network (ANN)[J]. Expert Systems with Applications, 2010, 37(6): 4168-4181 doi: 10.1016/j.eswa.2009.11.006 [8] AMAR M, GONDAL I, WILSON C. Vibration spectrum imaging: a novel bearing fault classification approach[J]. IEEE Transactions on Industrial Electronics, 2015, 62(1): 494-502 doi: 10.1109/TIE.2014.2327555 [9] GUO X J, CHEN L, SHEN C Q. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis[J]. Measurement, 2016, 93: 490-502 doi: 10.1016/j.measurement.2016.07.054 [10] PAN S J, YANG Q. A survey on transfer learning[J]. IEEE Transactions on Knowledge and Data Engineering, 2010, 22(10): 1345-1359 doi: 10.1109/TKDE.2009.191 [11] SOHAIB M, KIM C H, KIM J M. A hybrid feature model and deep-learning-based bearing fault diagnosis[J]. Sensors, 2017, 17(12): 2876 doi: 10.3390/s17122876 [12] LI X, JIA X D, ZHANG W, et al. Intelligent cross-machine fault diagnosis approach with deep auto-encoder and domain adaptation[J]. Neurocomputing, 2020, 383: 235-247 doi: 10.1016/j.neucom.2019.12.033 [13] CHEN D M, YANG S, ZHOU F N. Incipient fault diagnosis based on dnn with transfer learning[C]//International Conference on Control, Automation and Information Sciences (ICCAIS). Hangzhou: IEEE, 2018: 303-308 [14] 邵海东, 张笑阳, 程军圣, 等. 基于提升深度迁移自动编码器的轴承智能故障诊断[J]. 机械工程学报, 2020, 56(9): 84-90 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202009011.htmSHAO H D, ZHANG X Y, CHENG J S, et al. Intelligent fault diagnosis of bearing using enhanced deep transfer Auto-encoder[J]. Journal of Mechanical Engineering, 2020, 56(9): 84-90 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202009011.htm [15] ZHUANG Z L, LV H C, XU J, et al. A deep learning method for bearing fault diagnosis through stacked residual dilated convolutions[J]. Applied Sciences, 2019, 9(9): 1823 doi: 10.3390/app9091823 [16] HOLIGHAUS N, DORFLER M, VELASCO G A, et al. A framework for invertible, real-time constant-Q transforms[J]. IEEE Transactions on Audio, Speech, and Language Processing, 2013, 21(4): 775-785 doi: 10.1109/TASL.2012.2234114 [17] OBERLIN T, MEIGNEN S, PERRIER V. The fourier-based synchrosqueezing transform[C]//2014 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP). Florence, Italy: IEEE, 2014 [18] ANTONI J. Fast computation of the kurtogram for the detection of transient faults[J]. Mechanical Systems and Signal Processing, 2007, 21(1): 108-124 doi: 10.1016/j.ymssp.2005.12.002 [19] KRIZHEVSKY A, SUTSKEVER I, HINTON G E. ImageNet classification with deep convolutional neural networks[J]. Communications of the ACM, 2017, 60(6): 84-90 doi: 10.1145/3065386 [20] TAN C Q, SUN F C, KONG T, et al. A survey on deep transfer learning[C]//27th Artificial Neural Networks and Machine Learning-ICANN 2018 Rhodes: Springer, 2018 [21] 崔佳旭, 杨博. 贝叶斯优化方法和应用综述[J]. 软件学报, 2018, 29(10): 3068-3090 https://www.cnki.com.cn/Article/CJFDTOTAL-RJXB201810011.htmCUI J X, YANG B. Survey on bayesian optimization methodology and applications[J]. Journal of Software, 2018, 29(10): 3068-3090 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-RJXB201810011.htm [22] LOU X S, LOPARO K A. Bearing fault diagnosis based on wavelet transform and fuzzy inference[J]. Mechanical Systems and Signal Processing, 2004, 18(5): 1077-1095 doi: 10.1016/S0888-3270(03)00077-3 [23] SANTOS P, MAUDES J, BUSTILLO A. Identifying maximum imbalance in datasets for fault diagnosis of gearboxes[J]. Journal of Intelligent Manufacturing, 2018, 29(2): 333-351 doi: 10.1007/s10845-015-1110-0 [24] VAN DER MAATEN L. Accelerating t-SNE using tree-based algorithms[J]. Journal of Machine Learning Research, 2014, 15(1): 3221-3245 -

下载:

下载: