Quantitative Research on Fault Size of Rolling Bearing in Vibrating Machine

-

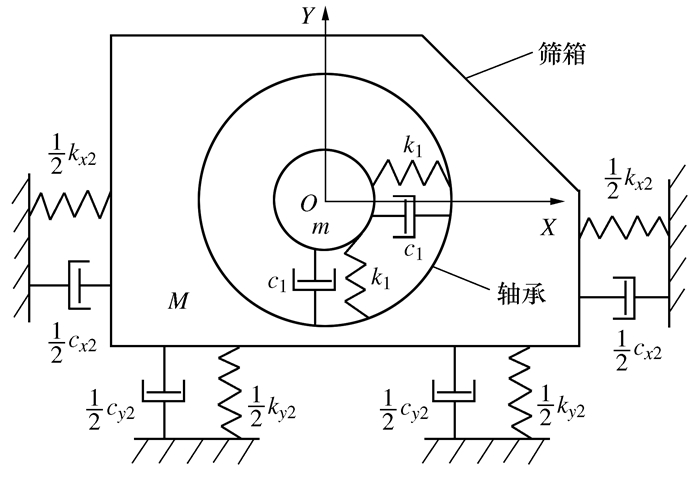

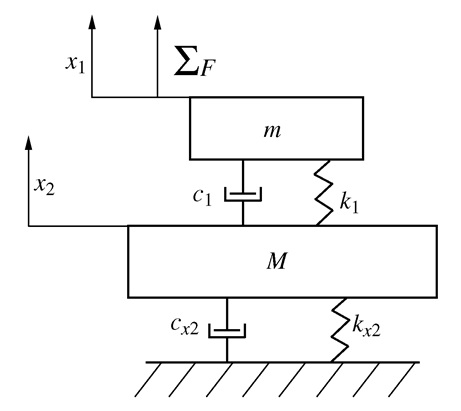

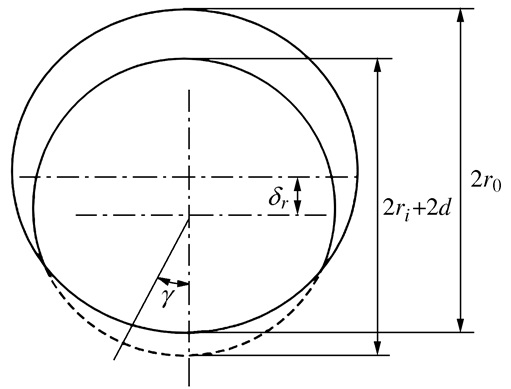

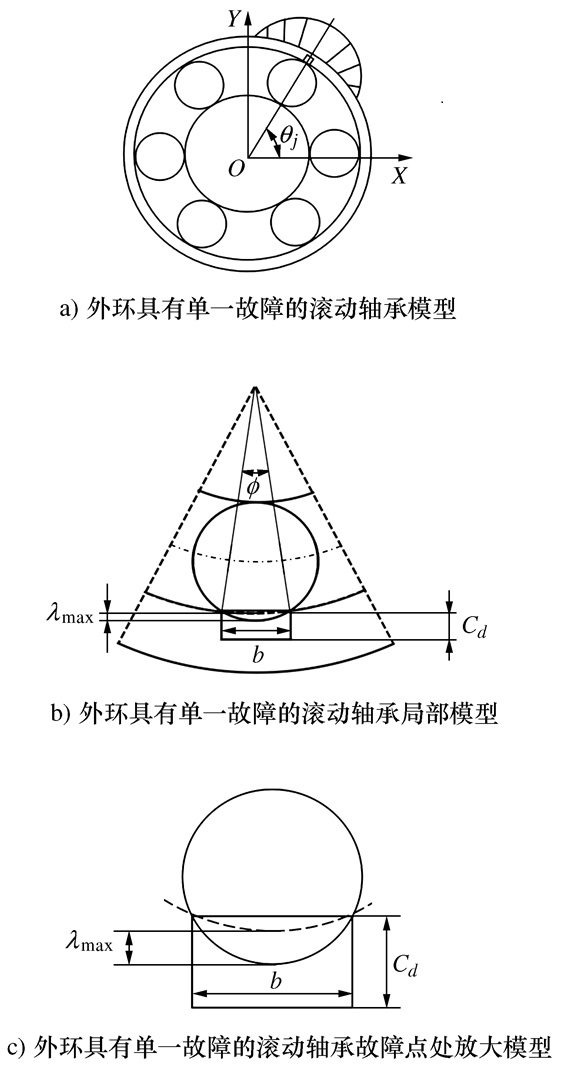

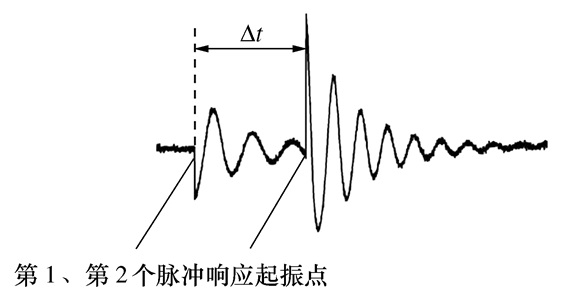

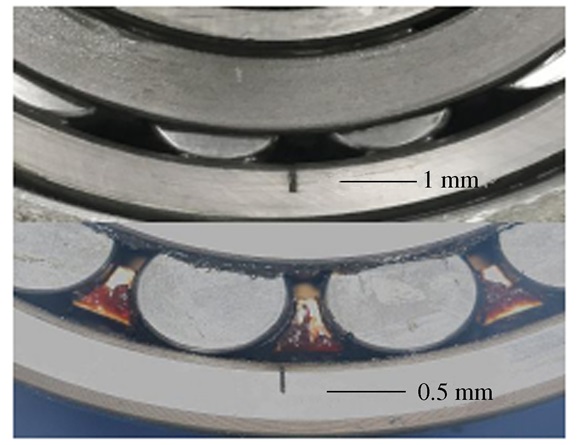

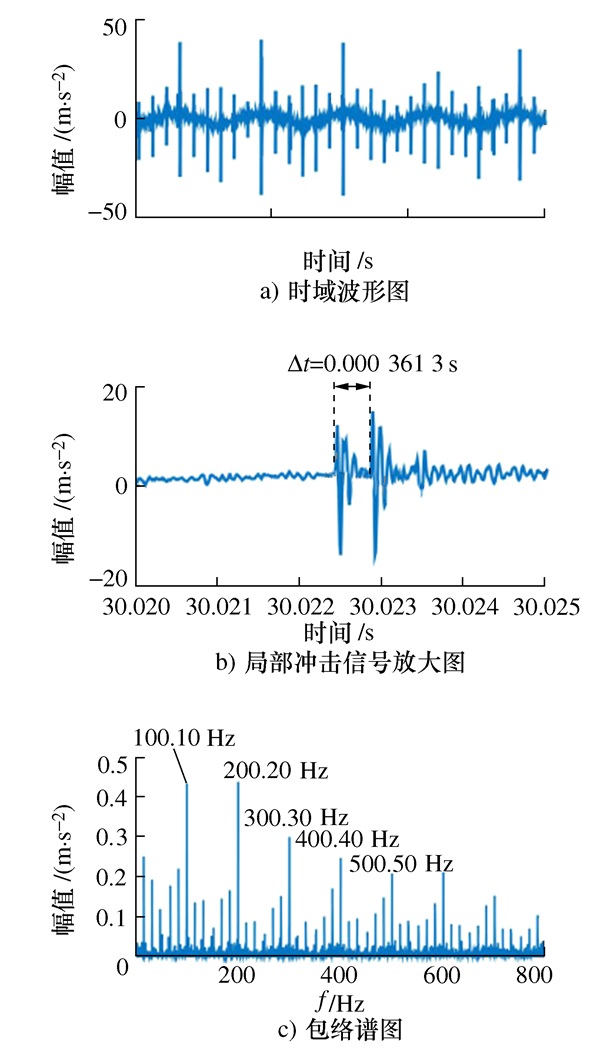

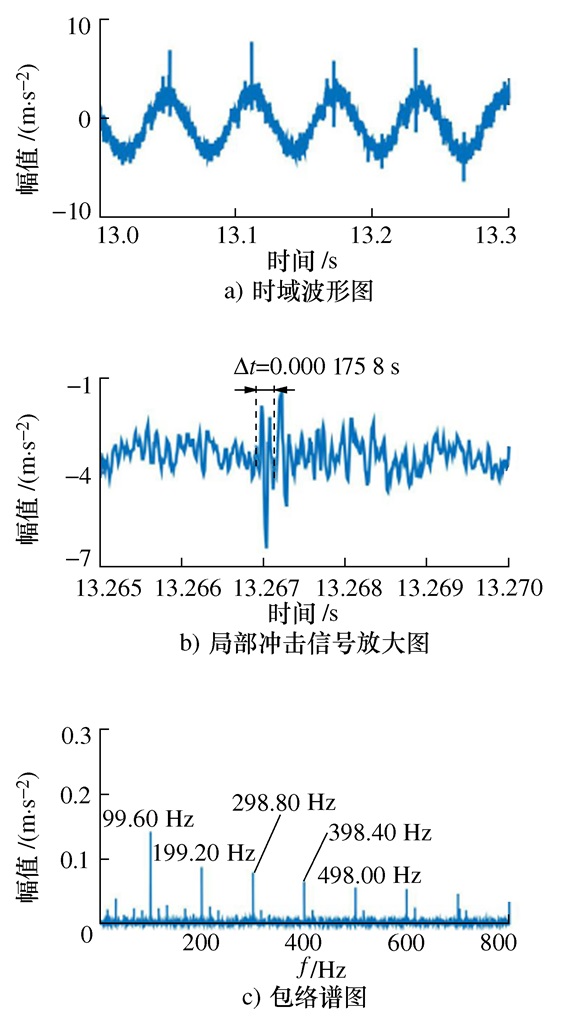

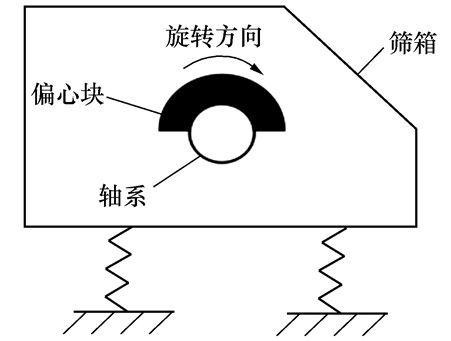

摘要: 针对振动机械滚动轴承故障尺寸量化的问题,通过对振动机械滚动轴承故障特征的分析,基于Hertz接触理论考虑局部单一故障尺寸对接触变形的影响,引入载荷分布区,建立振动机械滚动轴承外环单一局部损伤故障双冲击现象动力学模型。根据此模型进行仿真并在圆振动筛上对两组不同缺陷尺寸的轴承进行了实验研究。结果表明,因滚动体滚过缺陷而产生的双冲击信号,依据双冲击信号的时间间隔对轴承故障宽度尺寸进行量化,平均准确率达96%以上,验证了模型的正确性及此方法应用于振动机械滚动轴承故障尺寸量化的可行性。Abstract: Aiming at the problem of quantifying the severity of vibrating mechanical rolling bearing fault, by analyzing the fault characteristics of rolling bearings, the influence of local single fault size on contact deformation is considered by Hertz contact theory; and by introducing load distribution area, a dynamic model of double impact phenomenon of a single local damage fault in the outer ring of rolling bearings is established. According to this model, two groups of bearings with different defect sizes are simulated and test on a circular vibrating screen. The results show that the rolling element produces double shock signal through defects. The rolling bearing fault size is quantified according to the time interval of double shock signal, and the average accuracy is over 96%, which verifies the correctness of the model and the feasibility of applying this method to the fault quantification of rolling bearings in vibrating machine.

-

Key words:

- fault size quantification /

- rolling bearing /

- vibrating machine /

- double shock signal

-

图 5 滚动轴承径向位移[20]

表 1 调心滚子轴承22315CA/W33参数

轴承外径/mm 轴承内径/mm 轴承节圆直径/mm 接触角/(°) 滚动体直径/mm 滚动体数目/个 缺陷宽度/mm 160 75 117.5 12 21 15×2 0.5和1 表 2 双冲击信号时间间隔

故障大小/mm 仿真双冲击时间/s 实验双冲击时间/s 理论与实验准确率/% 理论与实验平均准确率/% 1 0.000 360 293 0.000 371 1 97.09 97.36 1 0.000 351 5 97.56 1 0.000 361 3 99.72 1 0.000 341 8 94.87 1 0.000 351 5 97.56 0.5 0.000 180 145 0.000 185 5 97.11 96.32 0.5 0.000 175 8 97.59 0.5 0.000 166 1 92.20 0.5 0.000 185 5 97.11 0.5 0.000 175 8 97.59 -

[1] GRIFFITH A A. The phenomena of rupture and flow in solids[J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 1921, 221(582-593): 163-198 http://adsabs.harvard.edu/abs/1921rspta.221..163g [2] PARIS P, Erdogan F. A critical analysis of crack propagation laws[J]. Journal of Fluids Engineering, 1963, 85(4): 528-533 http://www.researchgate.net/publication/216756691_A_critical_analysis_of_crack_propagation_laws/reviews [3] JANSON J. Dugdale-crack in a material with continuous damage formation[J]. Engineering Fracture Mechanics, 1977, 9: 891-899 doi: 10.1016/0013-7944(77)90010-8 [4] 张龙, 毛志德, 熊国良, 等. 滚动轴承故障诊断的自适应包络谱谱峰因子算法[J]. 机械科学与技术, 2019, 38(4): 507-514 doi: 10.13433/j.cnki.1003-8728.20180244ZHANG L, MAO Z D, XIONG G L, et al. Adaptive fault diagnosis of rolling bearings based on crest factor of envelope spectrum[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(4): 507-514 (in Chinese) doi: 10.13433/j.cnki.1003-8728.20180244 [5] QIAN Y N, YAN R Q, HU S J. Bearing degradation evaluation using recurrence quantification analysis and Kalman filter[J]. IEEE Transactions on Instrumentation and Measurement, 2014, 63(11): 2599-2610 doi: 10.1109/TIM.2014.2313034 [6] WANG P, WANG H, YAN R Q. Bearing degradation evaluation using improved cross recurrence quantification analysis and nonlinear auto-regressive neural network[J]. IEEE Access, 2019, 7: 38937-38946 doi: 10.1109/ACCESS.2019.2906388 [7] HOSEINZADEH M S, KHADEM S E, SADOOGHI M S. Quantitative diagnosis for bearing faults by improving ensemble empirical mode decomposition[J]. ISA Transactions, 2018, 83: 261-275 doi: 10.1016/j.isatra.2018.09.008 [8] ZHANG X Y, LIANG Y T, ZHOU J Z, et al. A novel bearing fault diagnosis model integrated permutation entropy, ensemble empirical mode decomposition and optimized SVM[J]. Measurement, 2015, 69: 164-179 doi: 10.1016/j.measurement.2015.03.017 [9] ZHANG Y, TANG B P, HAN Y, et al. Bearing performance degradation assessment based on time-frequency code features and SOM network[J]. Measurement Science and Technology, 2017, 28(4): 045601 doi: 10.1088/1361-6501/aa56c9 [10] SU Z Q, TANG B P, LIU Z R, et al. Multi-fault diagnosis for rotating machinery based on orthogonal supervised linear local tangent space alignment and least square support vector machine[J]. Neurocomputing, 2015, 157: 208-222 doi: 10.1016/j.neucom.2015.01.016 [11] KIM H E, TAN A C C, MATHEW J, et al. Bearing fault prognosis based on health state probability estimation[J]. Expert Systems with Applications, 2012, 39(5): 5200-5213 doi: 10.1016/j.eswa.2011.11.019 [12] SINGH S, KÖPKE U G, HOWARD C Q, et al. Analyses of contact forces and vibration response for a defective rolling element bearing using an explicit dynamics finite element model[J]. Journal of Sound and Vibration, 2014, 333(21): 5356-5377 doi: 10.1016/j.jsv.2014.05.011 [13] 罗茂林, 郭瑜, 伍星. 考虑冲击力的球轴承外圈剥落缺陷双冲击现象动力学建模[J]. 振动与冲击, 2019, 38(14): 48-54 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201914007.htmLUO M L, GUO Y, WU X. Dynamic modeling of the dual-impulse behavior produced by a spall on the outer race of a ball bearing considering impact forces[J]. Journal of Vibration and Shock, 2019, 38(14): 48-54 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201914007.htm [14] 罗茂林, 郭瑜, 伍星. 基于时变接触刚度的球轴承双冲击现象动力学建模[J]. 振动工程学报, 2018, 31(5): 875-882 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC201805018.htmLUO M L, GUO Y, WU X. Dynamic modeling for double impulses behavior of a spalled ball bearing based on time-varying contact stiffness[J]. Journal of Vibration Engineering, 2018, 31(5): 875-882 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC201805018.htm [15] 崔玲丽, 张宇, 巩向阳, 等. 基于振动响应机理的轴承故障定量诊断及量化分析[J]. 北京工业大学学报, 2015, 41(11): 1681-1687 https://www.cnki.com.cn/Article/CJFDTOTAL-BJGD201511020.htmCUI L L, ZHANG Y, GONG X Y, et al. Vibration mechanism based quantitative diagnosis and quantization analysis of rolling bearing fault[J]. Journal of Beijing University of Technology, 2015, 41(11): 1681-1687 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BJGD201511020.htm [16] 康伟, 郭瑜, 伍星. 基于双冲击特征的无转速计混合陶瓷球轴承剥落区宽度估计[J]. 振动与冲击, 2017, 36(20): 1-5, 22 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201720001.htmKANG W, GUO Y, WU X. Spall Size estimation of faulty hybrid ceramic ball bearings without a speed meter based on double impulses[J]. Journal of Vibration and Shock, 2017, 36(20): 1-5, 22 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201720001.htm [17] 孙守保, 郭瑜, 伍星. 基于声发射信号的滚动轴承外圈疲劳剥落故障双冲击特征提取[J]. 振动与冲击, 2017, 36(4): 1-6, 20 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201704001.htmSUN S B, GUO Y, WU X. Double impulse phenomenon extraction of outer race spalled rolling element bearings based on acoustic emission signals[J]. Journal of Vibration and Shock, 2017, 36(4): 1-6, 20 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201704001.htm [18] 郭宝良, 段志善, 郑建校, 等. 振动机械滚动轴承两点点蚀故障诊断研究[J]. 振动与冲击, 2013, 32(7): 58-63 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201307014.htmGUO B L, DUAN Z S, ZHENG J X, et al. Double-point pitting corrosion fault diagnosis for rolling bearings of a vibrating machine[J]. Journal of Vibration and Shock, 2013, 32(7): 58-63 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201307014.htm [19] 郭宝良, 段志善, 郑建校, 等. 振动机械滚动轴承单点点蚀故障诊断研究[J]. 振动工程学报, 2012, 25(5): 610-618 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC201205019.htmGUO B L, DUAN Z S, ZHENG J X, et al. Fault diagnosis of single-point pitting corrosion for rolling bearing of vibrating machine[J]. Journal of Vibration Engineering, 2012, 25(5): 610-618 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC201205019.htm [20] HARRIS T A, KOTZALAS M N. Advanced concepts of bearing technology: rolling bearing analysis[M]. 5th ed. New York: Taylor & Francis Group, 2007 -

下载:

下载: