Effect of Ultrasonic Strengthening on Fatigue Property of 30CrMnSiNi2A High-strength Steel

-

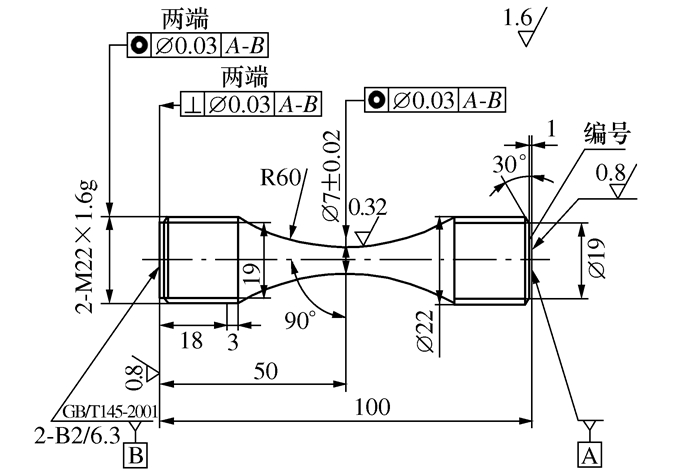

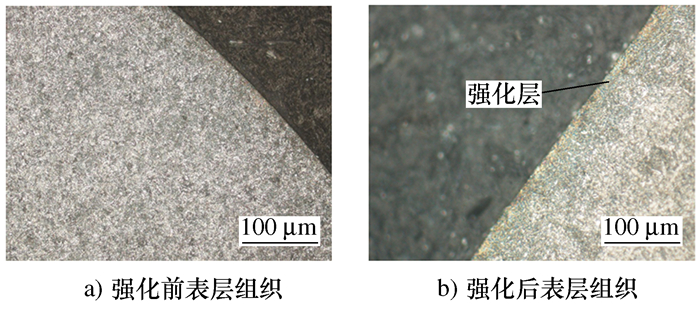

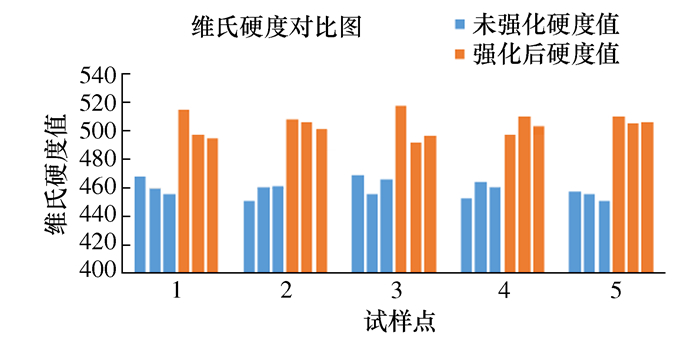

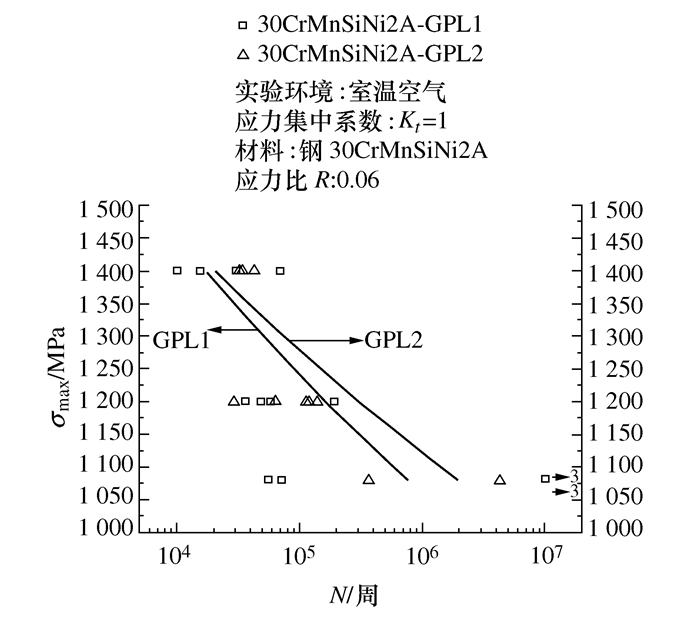

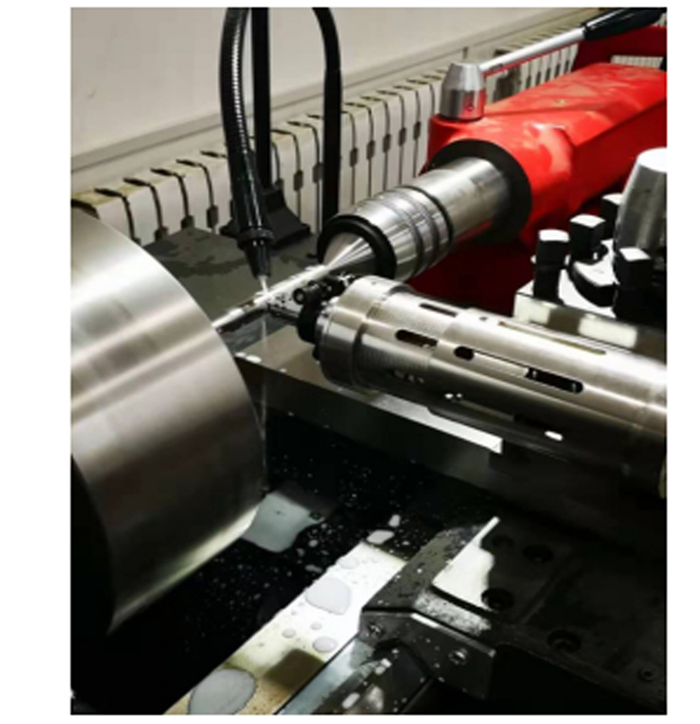

摘要: 超声强化技术可用来改善材料表面完整性以提高其疲劳性能。本文针对超声滚压强化对低合金高强钢疲劳性能的影响进行研究,通过分析超声强化的强化机理及疲劳试样实验,采用金相显微镜、微观硬度仪及扫描电镜对30CrMnSiNi2A疲劳试样进行微观结构及显微硬度的测试,结果表明,经过超声强化后试样表面出现一层强化层,组织更为细密,显微维氏硬度与未表面强化的试样相比提高了9.8%。在1 400 MPa应力作用下,30CrMnSiNi2A高强钢试样的疲劳寿命较传统抛光下的试样增加了38.4%。Abstract: Ultrasonic strengthening technology can be used to improve the surface integrity of materials in order to increase the fatigue life. The effect of the ultrasonic rolling strengthening on the fatigue property of high-strength steel was studied. Metallographic microscope, microhardness tester and scanning electron microscope were utilized to analyze microstructure and microhardness of the strengthened specimens, and the results showed that the strengthened layer can be obtained after ultrasonic strengthening treatment, and the microstructure become finer, the microhardness can be improved by 9.8% as well. At the same time, the fatigue life of the 30CrMnSiNi2A high-strength steel can be increased by 38.4% comparing with the polished specimens at a test stress of 1 400 MPa.

-

Key words:

- ultrasonic strengthening /

- high-strength steel /

- fatigue property

-

表 1 30CrMnSiNi2A高强钢的化学成分

% w(C) w(Mn) w(Si) w(Cr) w(Ni) w(S) w(Fe) 0.31 1.20 1.10 1.12 1.65 0.016 余量 表 2 硬度数据处理结果

试样材料 试样状态 维氏硬度

均值/HV维氏硬度

标准差30CrMnSiNi2A 未强化 459.2 5.937 超声强化后 504.5 7.316 表 3 钢30CrMnSiNi2A(Kt=1)试样疲劳试验结果

表面状态 σmax/MPa N/千周 GPL1 1 400 69.9, 30.3, 15.6, 10.1, 30.8 1 200 48.7, 61.4, 192.3, 35.8, 58.1 GPL2 1 400 34.6, 33.4, 31.6, 42.3, 33.8 1 200 29.3, 138.3, 63.4, 112, 119.5 表 4 钢30CrMnSiNi2A(Kt=1)试样S-N曲线拟合结果

试验环境 表面状态 应力比 S-N曲线拟合方程 室温空气 GPL1

GPL2R=0.06 lgN=50.077-14.569×lgσmax

lgN=59.734-17.617×lgσmax -

[1] 吕新颖, 江鹏, 张宪政, 等. 30CrMnSiA钢焊接接头疲劳特性研究[J]. 科学技术与工程, 2015, 15(21): 105-108 https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS201521021.htmLV X Y, JIANG P, ZHANG X Z, et al. Fatigue characteristics of 30CrMnSiA welded joints[J]. Science Technology and Engineering, 2015, 15(21): 105-108 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS201521021.htm [2] 高玉魁, 殷源发, 李向斌, 等. 喷丸强化对0Cr13Ni8Mo2Al钢疲劳性能的影响[J]. 材料工程, 2001(12): 46-48 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC200112014.htmGAO Y K, YIN Y F, LI X B, et al. Influence of shot peening on fatigue property for 0Cr13Ni8Mo2Al steel[J]. Journal of Materials Engineering, 2001(12): 46-48 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC200112014.htm [3] KIM S, JIN K, SUNG W, et al. Effect of lack of penetration on the fatigue strength of high strength steel butt weld[J]. KSME Journal, 1994, 8(2): 191-197 doi: 10.1007/BF02953268 [4] OKAWA T, SHIMANUKI H, FUNATSU Y, et al. Effect of preload and stress ratio on fatigue strength of welded joints improved by ultrasonic impact treatment[J]. Welding in the World, 2013, 57(2): 235-241 doi: 10.1007/s40194-012-0018-y [5] SÁNCHEZ L, GUTIÉRREZ-SOLANA F, PESQUERA D. Fatigue behaviour of punched structural plates[J]. Engineering Failure Analysis, 2004, 11(5): 751-764 doi: 10.1016/j.engfailanal.2003.10.002 [6] KUMAR S, CHATTOPADHYAY K, SINGH S R, et al. Surface nanostructuring of Ti-6Al-4V alloy through ultrasonic shot peening[J]. International Journal of Surface Science and Engineering, 2017, 11(1): 23-35 doi: 10.1504/IJSURFSE.2017.082949 [7] XU C, SHENG G M, WANG H D, et al. Effect of high energy shot peening on the microstructure and mechanical properties of Mg/Ti joints[J]. Journal of Alloys and Compounds, 2017, 695: 1383-1391 doi: 10.1016/j.jallcom.2016.10.262 [8] LIU D, LIU D X, ZHANG X H, et al. An investigation of fretting fatigue behavior and mechanism in 17-4PH stainless steel with gradient structure produced by an ultrasonic surface rolling process[J]. International Journal of Fatigue, 2020, 131: 105340 doi: 10.1016/j.ijfatigue.2019.105340 [9] KHERADMANDFARD M, KASHANI-BOZORG S F, KANG K H, et al. Simultaneous grain refinement and nanoscale spinodal decomposition of β phase in Ti-Nb-Ta-Zr alloy induced by ultrasonic mechanical impacts[J]. Journal of Alloys and Compounds, 2018, 738: 540-549 doi: 10.1016/j.jallcom.2017.12.049 [10] AMANOV A, UMAROV R. The effects of ultrasonic nanocrystal surface modification temperature on the mechanical properties and fretting wear resistance of Inconel 690 alloy[J]. Applied Surface Science, 2018, 441: 515-529 doi: 10.1016/j.apsusc.2018.01.293 [11] SONG Y N, WANG H D, XU B S, et al. Effect of fretting wear on very high cycle bending fatigue behaviors of FV520B steel[J]. Tribology International, 2016, 103: 132-138 doi: 10.1016/j.triboint.2016.06.033 [12] YANG Q, ZHOU W L, GAI P T, et al. Investigation on the fretting fatigue behaviors of Ti-6Al-4V dovetail joint specimens treated with shot-peening[J]. Wear, 2017, 372-373: 81-90 doi: 10.1016/j.wear.2016.12.004 [13] 李礼. 超声深滚材料表面强化技术及其抗疲劳机理研究[D]. 北京: 装甲兵工程学院, 2009LI L. Research on ultrasonic deep rolling technique for material's surface enhencement and its anti-fatigue mechanisms[D]. Beijing: Academy of Armored Force Engineering, 2009 (in Chinese) [14] JAYARAMAN N, PREVÉY P, ONTKO N, et al. Comparison of mechanical suppression by shot peening and low plasticity burnishing to mitigate SCC and corrosion fatigue failures in 300M landing gear steel[C]//Proceedings of ICSP 9. Pairs, 2005 [15] 谢俊峰. 典型飞机材料超声深滚强化与超声焊接修复机理研究[D]. 北京: 装甲兵工程学院, 2013XIE J F. Research on mechanisms of ultrasonic deep rolling enhancement and ultrasonic welding restoration of typical aircraft materials[D]. Beijing: Academy of Armored Force Engineering, 2013 (in Chinese) [16] 王婷, 王东坡, 沈煜, 等. 超声表面滚压加工参数对40Cr表面粗糙度的影响[J]. 天津大学学报, 2009, 42(2): 168-172 https://www.cnki.com.cn/Article/CJFDTOTAL-TJDX200902015.htmWANG T, WANG D P, SHEN Y, et al. Effect of ultrasonic surface rolling processing parameters on 40Cr surface roughness[J]. Journal of Tianjin University, 2009, 42(2): 168-172 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TJDX200902015.htm [17] ZHENG J X, LIU C S, ZHANG Y M. Basic research on ultrasonic extrusion for 45 steel shaft[J]. Key Engineering Materials, 2011, 455: 288-292 http://www.scientific.net/KEM.455.288 [18] 任学冲, 陈利钦, 刘鑫贵, 等. 表面超声滚压处理对高速列车车轴钢疲劳性能的影响[J]. 材料工程, 2015, 43(12): 1-5 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201512002.htmREN X C, CHEN L Q, LIU X G, et al. Effects of surface ultrasonic rolling processing on fatigue properties of axle steel used on high speed train[J]. Journal of Materials Engineering, 2015, 43(12): 1-5 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201512002.htm -

下载:

下载: