Exploring Structural Optimization and Performance of Magnetic Flux Type Radial Flow Magnetorheological Valve

-

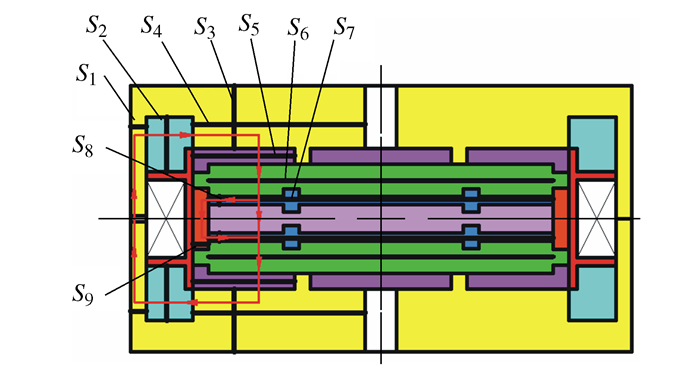

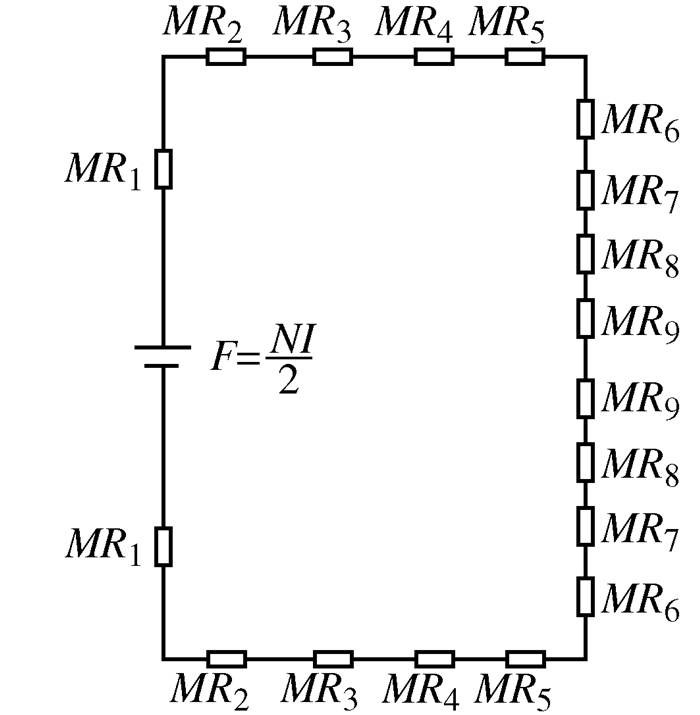

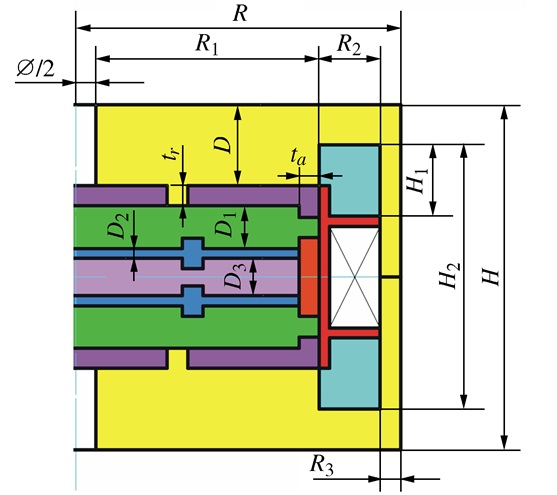

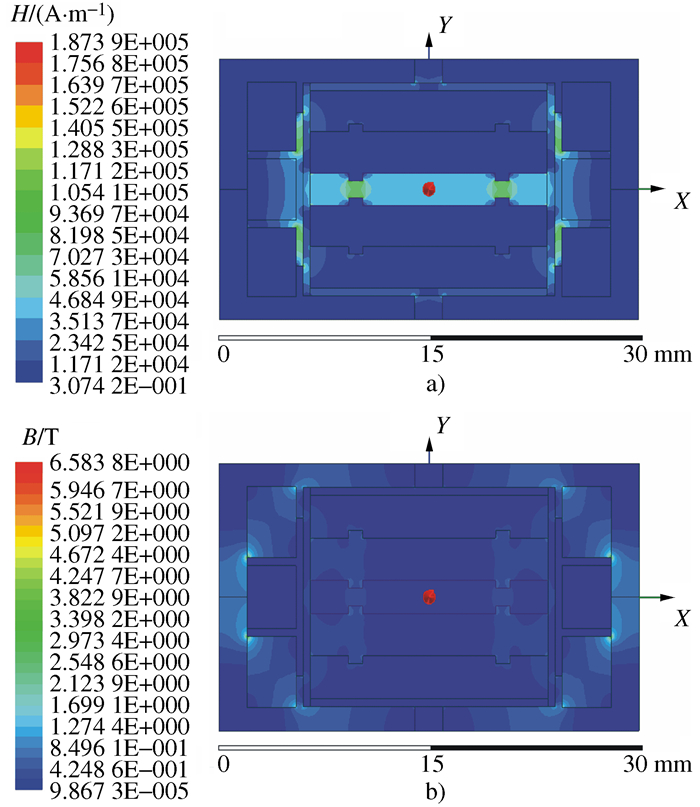

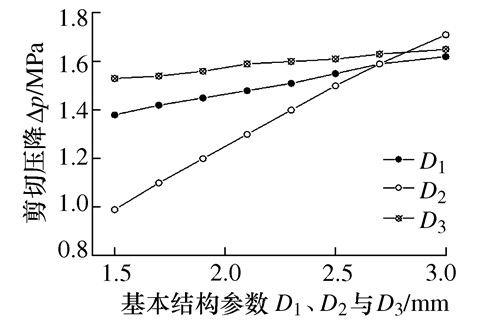

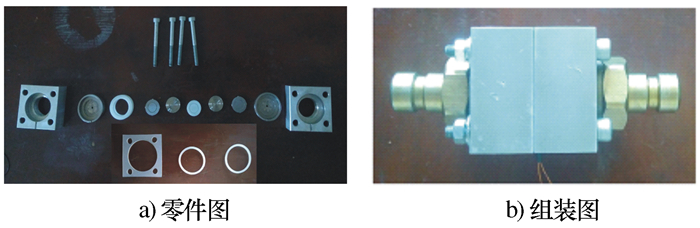

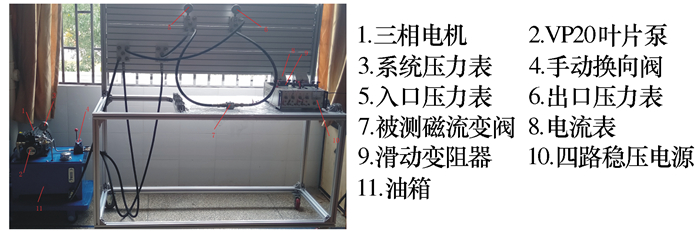

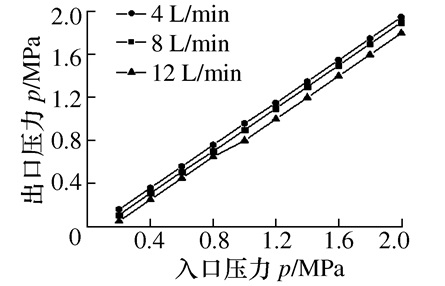

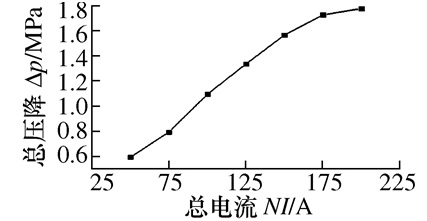

摘要: 针对典型径向流磁流变阀电源能耗过大的问题,使用不同软磁材料对阀芯进行分割式组合,提出并设计导磁型径向流磁流变阀结构。由于软磁材料的导磁性能不同,将软磁材料进行排列组合,从而使得阀芯处的磁能损耗降低,同时诱导磁场进入环形轴向间隙内,增加磁场对磁流变液的作用面积。采用拉格朗日乘子法结合拟牛顿法,对阀体基本结构进行优化设计,并且利用Maxwell对优化后的导磁型径向流磁流变阀进行仿真,仿真结果与理论结果接近,充分证明优化结果的可靠性。实验结果表明:导磁型径向流磁流变阀的电源能耗比典型径向流磁流变阀降低33.3%,并且在最大压降值为1.8 MPa时,体积减少37.7%。Abstract: Due to the excessive energy consumption of the typical radial flow magnetorheological valve power supply, different soft magnetic materials are used to split the valve core, and the structure of the magnetic flux type radial flow magnetic rheological valve is designed. Because of their different magnetic permeability, the soft magnetic materials are arranged and combined so that the magnetic energy loss at the valve core is reduced, and the magnetic field is induced to enter the annular axial gap, thereby increasing the area of action of the magnetic field on the magnetorheological fluid. The Lagrangian multiplier method together with the quasi-Newton method is used to search for the basic structural optimization of the valve body. The optimized magnetic flux type radial flow magnetorheological valve is simulated with the Maxwell software. The simulation results are in close agreement with the theoretical results, thus proving the reliability of the optimization results. The simulation results show that the energy utilization of the magnetic flux type radial flow magneto-rheological valve is 33.3% higher than that of the typical radial flow magneto-rheological valve and that its volume is reduced by 37.7% when the maximum pressure drops by 1.8 MPa.

-

Key words:

- magnetorheological valve /

- optimization /

- pressure drop /

- energy utilization /

- finite element analysis

-

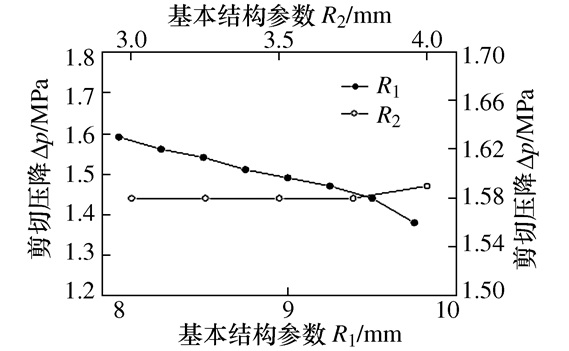

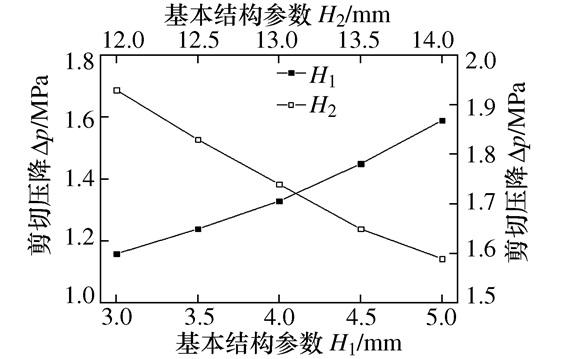

表 1 不同ta(tr)值的最佳决策变量

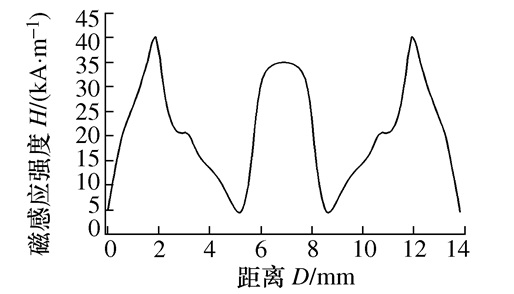

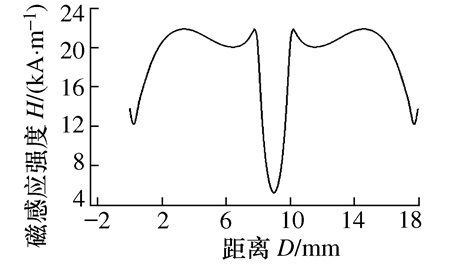

ta/mm tr/mm R1/mm D1/mm D2/mm D3/mm Δpy/MPa 0.5 0.5 8.0 2.70 2.70 2.10 1.592 0.6 0.6 8.0 2.67 2.67 2.08 1.230 0.7 0.7 8.0 2.63 2.63 2.06 0.982 0.8 0.8 8.0 2.58 2.58 2.04 0.803 0.9 0.9 8.0 2.54 2.54 2.02 0.669 1.0 1.0 8.0 2.49 2.49 1.99 0.566 表 2 不同ta(tr)值的最佳决策变量对应的HMA值和HMR值

ta/mm tr/mm HMA/(kA·m-1) HMR/(kA·m-1) 0.5 0.5 41.0 9.1 0.6 0.6 36.1 9.6 0.7 0.7 32.0 9.96 0.8 0.8 28.5 10.1 0.9 0.9 25.6 10.2 1.0 1.0 23.1 10.3 表 3 单因素基本结构尺寸的取值范围

表 4 相关电磁参数取值表

参数 数值 总激励电流NI 200 A 端盖初始磁导率 160 导磁环初始磁导率 8 000 线圈架初始磁导率 1 导磁盘Ⅰ初始磁导率 15 导磁盘Ⅱ初始磁导率 100 000 导磁盘Ⅲ初始磁导率 3 磁流变液初始磁导率 5 -

[1] 李松晶, 阮健, 弓永军. 先进液压传动技术概论[M]. 哈尔滨: 哈尔滨工业大学出版社, 2008LI S J, QI J, GONG Y J. Introduction of advanced hydraulic transmission techniques[M]. Harbin: Harbin Institute of Technology Press, 2008 (in Chinese) [2] 王春行. 液压伺服控制系统[M]. 2版. 北京: 机械工业出版社, 1989WANG C X. Hydraulic servo control system[M]. 2nd ed. Beijing: China Machine Press, 1989 (in Chinese) [3] 朱传征, 沈骎, 徐超, 等. 钇铁氧体磁流体的制备及表征[J]. 华东师范大学学报, 2000(1): 68-73 https://www.cnki.com.cn/Article/CJFDTOTAL-HDSZ200001011.htmZHU C Z, SHEN Q, XU C, et al. The preparation and character of yttrium ferrite ferrofluid[J]. Journal of East China Normal University, 2000(1): 68-73 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HDSZ200001011.htm [4] 杜庆波. 氧化铁纳米材料的制备、表征及磁性研究[J]. 硅酸盐通报, 2016, 35(9): 2922-2924, 2929 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201609039.htmDU Q B. Preparation, characterization and magnetic properties of iron oxide nanomaterials[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(9): 2922-2924, 2929 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201609039.htm [5] 王四棋, 李德才, 居本祥. 一种油酸包覆磁性颗粒类磁流变液的制备和性能研究[J]. 功能材料, 2016, 47(7): 7153-7156, 7162 https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL201607029.htmWANG S Q, LI D C, JU B X. Preparation and properties of a magnetorheological fluid with oleic acid-coated magnetic particles[J]. Journal of Functional Materials, 2016, 47(7): 7153-7156, 7162 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL201607029.htm [6] 孙春丽, 徐赵东, 戴军. 混合包覆铁磁颗粒基磁流变液的测试及力学模型[J]. 东南大学学报, 2019, 49(2): 328-333 https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201902018.htmSUN C L, XU Z D, DAI J. Test and mechanical model of MR fluids based on magnetic particles coated by mixed materials[J]. Journal of Southeast University, 2019, 49(2): 328-333 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201902018.htm [7] 廖干良, 廖昌荣, 文慧, 等. 磁致链化对磁流变弹性体压阻效应的影响[J]. 复合材料学报, 2017, 34(9): 2085-2092 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201709026.htmLIAO G L, LIAO C R, WEN H, et al. Effects of particle pre-orientation via application of magentic field on the piezoresistivity of magnetorheological elastomer[J]. Acta Materiae Compositae Sinica, 2017, 34(9): 2085-2092 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201709026.htm [8] 司晨. 磁流变电液系统的优化设计与运动控制研究[D]. 杭州: 浙江大学, 2017SI C. Optimal design and motion control of magneto-rheological electro hy-draulic system[D]. Hangzhou: Zhejiang University, 2017 (in Chinese) [9] CAI S B, WEI W, WAN W W, et al. Study on the compliant joint based on magnetorheological fluid transmission: design, simulation and experiments[J]. Chinese Journal of Scientific Instrument, 2019, 40(1): 200-210 http://www.researchgate.net/publication/333201093_Study_on_the_compliant_joint_based_on_magnetorheological_fluid_transmission_Design_simulation_and_experiments [10] YOSHIDA K, SOGA T, KAWACHI M, et al. Magneto-rheological valve-integrated cylinder and its application[J]. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2010, 224(1): 31-40 doi: 10.1243/09596518JSCE740 [11] SALLOOM M Y, SAMAD Z. Finite element modeling and simulation of proposed design magneto-rheological valve[J]. International Journal of Advanced Manufacturing Technology, 2011, 54(5-8): 421-429 doi: 10.1007/s00170-010-2963-1 [12] 胡国良, 李海燕, 喻理梵, 等. 磁流变阀结构优化设计及性能分析研究现状[J]. 机床与液压, 2014, 42(5): 160-165 https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201405047.htmHU G L, LI H Y, YU L F, et al. Research status of structure optimization design and Characteristics analysis of magnetorheological valve[J]. Machine Tool & Hydraulics, 2014, 42(5): 160-165 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201405047.htm [13] 胡国良, 钟芳. 磁场结构对径向流磁流变阀动态性能的影响[J]. 农业机械学报, 2017, 48(9): 411-420, 401 https://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201709052.htmHU G L, ZHONG F. Influence of magnetic field structure on dynamic performance of radial magnetorheological valve[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 411-420, 401 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201709052.htm [14] SALLOOM M Y, SAMAD Z. Experimental test of magneto-rheological directional control valve[J]. Advanced Materials Research, 2011, 383-390: 5409-5413 doi: 10.4028/www.scientific.net/AMR.383-390.5409 [15] SALLOOM M Y, SAMAD Z. Magneto-rheological directional control valve[J]. The International Journal of Advanced Manufacturing Technology, 2012, 58(1-4): 279-292 doi: 10.1007/s00170-011-3377-4 -

下载:

下载: