Numerically Simulating Relationship of Process Parameters Between Droplet Ejection and Droplet Morphology

-

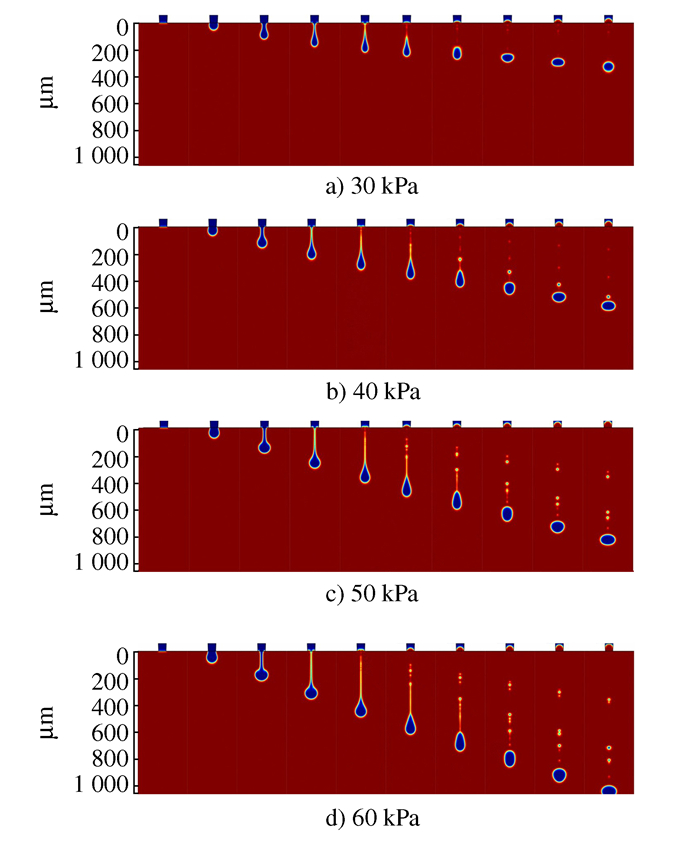

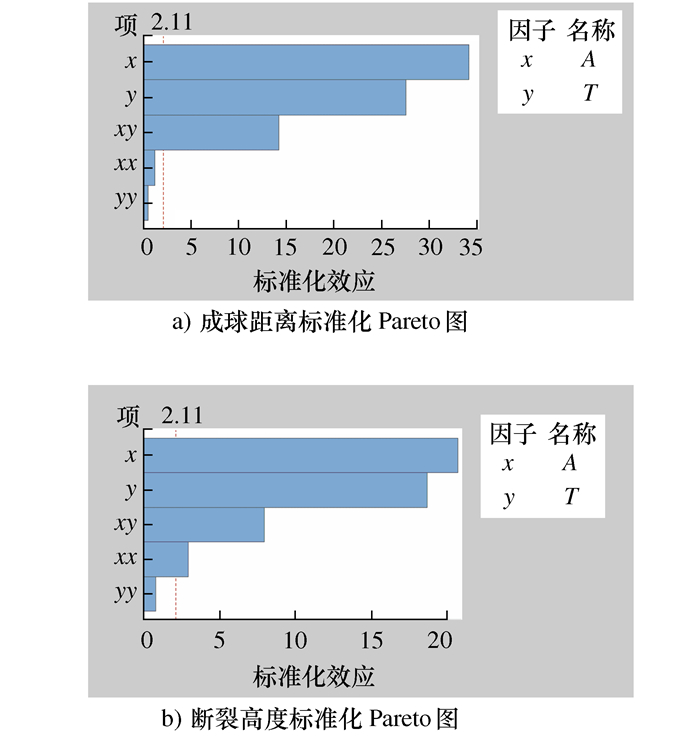

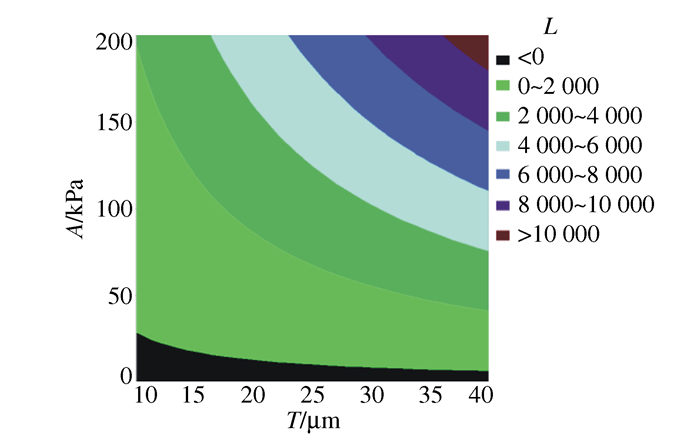

摘要: 以微滴喷射的增材制造技术为研究对象,采用守恒水平集方法建立了液滴喷射过程的数值仿真的物理数学模型。通过仿真实验分析了液滴喷射的流场分布,采用曲面响应法的中心复合设计建立了拟合模型并进行了修正,提出了液滴喷射过中液滴成球距离和断裂高度分别与入口处压强脉冲的幅值与脉宽的拟合关系式。模拟结果表明:在液滴喷射过程中喷嘴入处的压强脉冲的幅值与脉宽和液滴形态之间有密切的关系,压强幅值与脉宽之间存在一个临界关系,当不满足这个关系时液滴无法从喷嘴口喷出,只有当压强幅值与脉宽满足这个临界条件时,液滴才能够克服喷嘴口处的表面张力顺利喷出;在满足喷射条件的情况下压强幅值与脉宽时间越大,喷出的液滴成球距离越远;压强幅值与脉宽时间越小,喷出的液滴成球距离越近。

-

关键词:

- 微滴喷射 /

- Level Set方法 /

- 流场分析 /

- 曲面响应法

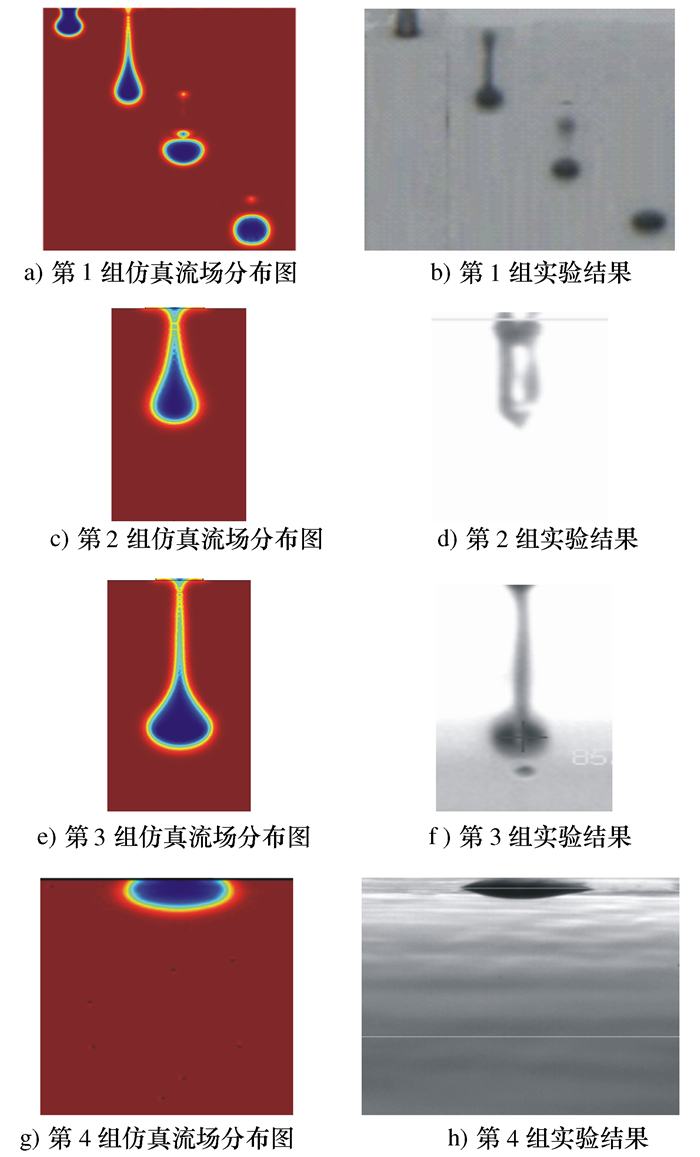

Abstract: This paper studies the additive manufacturing technology based on droplet ejection. The numerical calculation of the droplet ejection process was carried out with the level set method. After analyzing the flow field distribution of droplet ejection, the response surface method (RSM) is used to establish and then correct the fitting model. The fitting relations between the distance of droplets that form a ball and the fracture height under different parameters are put forward. According to the fitting relations, the morphology of the ejected droplets under different inlet pressure pulse conditions is predicted, and the reliability of the fitting relations is verified by comparing the prediction results with the simulation results. The simulation results show that the amplitude and pulse width of the pressure pulse at the nozzle inlet and the droplet morphology during the droplet ejection are closely related. There exists a critical relationship between the pressure amplitude and the pulse width. When this relationship is not satisfied, the droplet cannot be ejected from the nozzle. Only when the pressure amplitude and pulse width satisfy this critical relationship can droplets be ejected smoothly to overcome the surface tension. In the case of meeting the ejection conditions, the greater the amplitude and pulse width of the pressure pulse is, the farther the droplet is formed into a ball. The smaller the amplitude and pulse width of the pressure pulse is, the closer the droplets are to the ball.-

Key words:

- droplet ejection /

- level set /

- flow field analysis /

- response surface method

-

表 1 呋喃数脂物性参数

参数名称 数值 表面张力 4.32×10-2 N/m 动力黏度 9.757×10-3 Pa·s 接触角 32° 密度 1.120×103 kg/m3 表 2 模型汇总表

参数 S R-sq R-sq(调整) R-sq(预测) L 14.657 8 99.67% 99.62% 99.53% l 5.803 87 99.32% 99.16% 98.80% 表 3 成球距离预测

组号 脉宽T/μs 幅值A/kPa 仿真值/mm 拟合值 拟合值标准误差 95%置信区间 95%预测区间 1 12 50 394 414.558 5.884 06 (402.144, 426.972) (381.699, 447.417) 2 12 36 203 203.615 5.773 34 (191.434, 215.795) (170.844, 236.386) 3 17 42 614 612.169 6.574 59 (598.298, 626.041) (578.733, 645.606) 4 10 30 无法喷出 < 0 表 4 断裂高度预测

组号 脉宽T/μs 幅值A/kPa 仿真值/mm 拟合值 拟合值标准误差 95%置信区间 95%预测区间 1 12 50 212 213.285 2.392 31 (208.237, 218.332) (199.925, 226.644) 2 12 36 161 157.095 2.347 29 (152.143, 162.048) (143.771, 170.419) 3 17 42 253 274.855 2.673 06 (269.216, 280.495) (261.261, 288.450) 4 10 30 无法喷出 < 0 -

[1] Derby B. Additive manufacture of ceramics components by inkjet printing[J]. Engineering, 2015, 1(1): 113-123 doi: 10.15302/J-ENG-2015014 [2] Fromm J E. Numerical calculation of the fluid dynamics of drop-on-demand jets[J]. IBM Journal of Research and Development, 1984, 28(3): 322-333 doi: 10.1147/rd.283.0322 [3] Derby B. Inkjet printing of functional and structural materials: fluid property requirements, feature stability, and resolution[J]. Annual Review of Materials Research, 2010, 40: 395-414 doi: 10.1146/annurev-matsci-070909-104502 [4] Reis N, Derby B. Ink jet deposition of ceramic suspensions: modeling and experiments of droplet formation[J]. MRS Online Proceedings Library Archive, 2000, 625: 117-122 doi: 10.1557/PROC-625-117 [5] Reis N, Ainsley C, Derby B. Ink-jet delivery of particle suspensions by piezoelectric droplet ejectors[J]. Journal of Applied Physics, 2005, 97(9): 094903 doi: 10.1063/1.1888026 [6] Duineveld P C, de Kok M M, Buechel M, et al. Ink-jet printing of polymer light-emitting devices[C]//Proceedings Volume 4464, Organic Light-Emitting Materials and Devices V. San Diego, CA, United States: SPIE, 2002: 59-67 [7] Stow C D, Hadfield M G. An experimental investigation of fluid flow resulting from the impact of a water drop with an unyielding dry surface[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 1981, 373(1755): 419-441 http://rspa.royalsocietypublishing.org/content/373/1755/419.abstract [8] Carneiro J, Campos J B L M, Miranda J M. High viscosity polymeric fluid droplet formation in a flow focusing microfluidic device-Experimental and numerical study[J]. Chemical Engineering Science, 2019, 195: 442-454 doi: 10.1016/j.ces.2018.09.042 [9] Wu L Y, Liu X D, Zhao Y J, et al. Role of local geometry on droplet formation in axisymmetric microfluidics[J]. Chemical Engineering Science, 2017, 163: 56-67 doi: 10.1016/j.ces.2017.01.022 [10] Yu W, Liu X D, Zhao Y J, et al. Droplet generation hydrodynamics in the microfluidic cross-junction with different junction angles[J]. Chemical Engineering Science, 2019, 203: 259-284 doi: 10.1016/j.ces.2019.03.082 [11] 齐乐华, 罗俊, 李莉, 等. 均匀液滴喷射过程仿真与试验研究[J]. 机械工程学报, 2008, 44(12): 86-92 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200812016.htmQi L H, Luo J, Li L, et al. Simulation and experiment research of the uniform drolet spray process[J]. Chinese Journal of Mechanical Engineering, 2008, 44(12): 86-92 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200812016.htm [12] 杨敏官, 闫龙龙, 王育立, 等. 喷嘴入口条件对微液滴生成的影响[J]. 排灌机械工程学报, 2015, 33(3): 226-232 https://www.cnki.com.cn/Article/CJFDTOTAL-PGJX201503009.htmYang M G, Yan L L, Wang Y L, et al. Effects of nozzle inlet conditions on micro-droplet formation[J]. Journal of Drainage and Irrigation Machinery Engineering, 2015, 33(3): 226-232 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-PGJX201503009.htm [13] 刘赵淼, 徐元迪, 逄燕, 任等. 压电式微滴按需喷射的过程控制和规律[J]. 力学学报, 2019, 51(4): 1031-1042Liu Z M, Xu Y D, Pang Y, et al. Study of process control on piezoelectric drop-on-demand ejection[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(4): 1031-1042 (in Chinese) [14] 薛光怀, 贺永, 傅建中, 等. 压电式喷头的微滴喷射行为及其影响因素[J]. 光学精密工程, 2014, 22(8): 2166-2172 https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201408026.htmXue G H, He Y, Fu J Z, et al. Droplet jetting of piezoelectric printhead and corresponding effect factors[J]. Optics and Precision Engineering, 2014, 22(8): 2166-2172 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201408026.htm [15] Osher S, Sethian J A. Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations[J]. Journal of Computational Physics, 1988, 79(1): 12-49 doi: 10.1016/0021-9991(88)90002-2 [16] Olsson E, Kreiss G. A conservative level set method for two phase flow[J]. Journal of Computational Physics, 2005, 210(1): 225-246 doi: 10.1016/j.jcp.2005.04.007 -

下载:

下载: