An Improved Watershed Algorithm for Segmenting Tool Wear Images

-

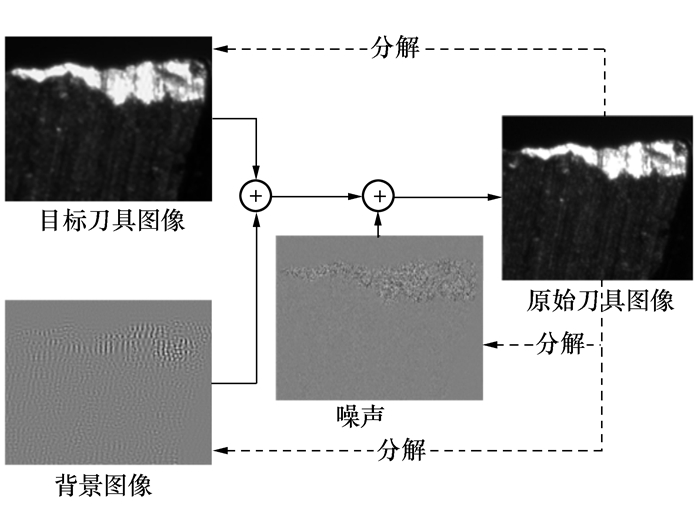

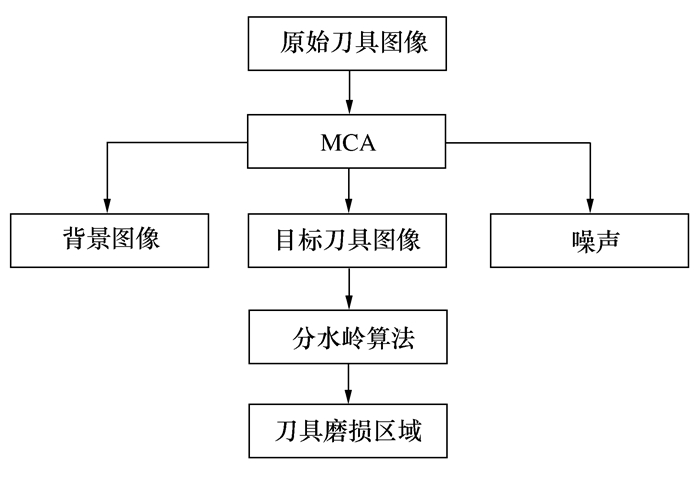

摘要: 原始刀具图像通常存在背景纹理复杂、噪声大等问题,导致磨损区域分割结果的准确性较差,为此本文提出了一种基于形态学成分分析(MCA)的改进分水岭算法,用于提取刀具磨损区域并估算其面积。首先分析了刀具磨损图像各组成成分的形态差异;然后研究了各成分对应字典的选取方法,将原始刀具图像分解成目标刀具图像、背景图像和噪声;最后对目标刀具图像使用分水岭算法提取磨损区域并估算面积。以铣刀磨损图像作为样本完成了多次方法验证,结果表明:传统分水岭算法的检测误差为80%左右,而该方法的检测误差为5%以下,可见使用该算法可以分割得到更加准确的磨损区域。Abstract: An original tool image usually has complex background texture and high noise, which lead to the poor accuracy of wear region segmentation. Therefore, an improved watershed algorithm based on morphological component analysis (MCA) is proposed to extract the tool wear region and estimate its area. Firstly, the morphological differences of the components of the tool wear image are analyzed. Then, the method for selecting the corresponding dictionary of each component is studied and used to decompose the original tool image into the target tool image, background image and noise. Finally, the watershed algorithm is used to extract the wear region of the target tool image and to estimate its area. Milling wear images are used as samples to perform a number of validations of the algorithm. The validation results show that the detection error of the traditional watershed algorithm is about 80%, while the detection error of our algorithm is less than 5%, so it is concluded that our algorithm can segment wear regions more accurately.

-

Key words:

- tool wear /

- image segmentation /

- morphological component analysis /

- watershed algorithm

-

表 1 刀具图像磨损面积估算

图像 手工 传统分水岭算法 本文算法 磨损区域面积/μm2 错检率/% 磨损区域面积/μm2 错检率/% 1 5 962.47 31 142.84 80.85 5 702.34 4.56 2 31 074.39 168 351.98 81.54 30 162.10 3.02 3 32 857.95 152 938.26 78.52 32 762.11 0.29 -

[1] 管声启, 洪奔奔, 梁洪, 等.高斯差分滤波显著性的刀具磨损检测[J].机械科学与技术, 2018, 37(2):276-279 doi: 10.13433/j.cnki.1003-8728.2018.0218Guan S Q, Hong B B, Liang H, et al. Tool wear detection using gauss filter saliency[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(2):276-279(in Chinese) doi: 10.13433/j.cnki.1003-8728.2018.0218 [2] 秦国华, 易鑫, 李怡冉, 等.刀具磨损的自动检测及检测系统[J].光学精密工程, 2014, 22(12):3332-3341 http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201412025Qin G H, Yi X, Li Y R, et al. Automatic detection technology and system for tool wear[J]. Optics and Precision Engineering, 2014, 22(12):3332-3341(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201412025 [3] 马英辉, 吴一全.基于二维Renyi交叉熵的刀具磨损图像分割[J].电子测量与仪器学报, 2016, 30(12):1869-1876 http://d.old.wanfangdata.com.cn/Periodical/dzclyyqxb201612011Ma Y H, Wu Y Q. Image segmentation for tool wear based on 2D Renyi cross entropy[J]. Journal of Electronic Measurement and Instrumentation, 2016, 30(12):1869-1876(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/dzclyyqxb201612011 [4] 管声启, 屈云仙, 高照元.小波域同态滤波的刀具磨损检测[J].机械科学与技术, 2013, 32(11):1703-1707 http://d.old.wanfangdata.com.cn/Periodical/jxkxyjs201311029Guan S Q, Qu Y X, Gao Z Y. A tool wear detection by wavelet homomorphism filtering[J]. Mechanical Science and Technology for Aerospace Engineering, 2013, 32(11):1703-1707(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jxkxyjs201311029 [5] 李姗姗, 刘丽冰, 李莉, 等.基于区域生长法的数控刀具磨损状态检测方法[J].制造技术与机床, 2017(2):132-136 http://d.old.wanfangdata.com.cn/Periodical/zzjsyjc201702031Li S S, Liu L B, Li L, et al. A method of CNC tool wear condition monitoring based on region growing arithmetic[J]. Manufacturing Technology & Machine Tool, 2017(2):132-136(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zzjsyjc201702031 [6] Atli A V, Urhan O, Ertürk S, et al. A computer vision- based fast approach to drilling tool condition monitoring[J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture, 2006, 220(9):1409-1415 doi: 10.1243/09544054JEM412 [7] Zhang J L, Zhang C, Guo S, et al. Research on tool wear detection based on machine vision in end milling process[J]. Production Engineering, 2012, 6(4-5):431-437 doi: 10.1007/s11740-012-0395-5 [8] 李鹏阳, 祝双武, 郝重阳, 等.基于改进型脉冲耦合神经网络的刀具磨损图像检测[J].西北工业大学学报, 2008, 26(2):194-199 doi: 10.3969/j.issn.1000-2758.2008.02.012Li P Y, Zhu S W, Hao C Y, et al. A more accurate algorithm for tool wear image detection using modified PCNN[J]. Journal of Northwestern Polytechnical University, 2008, 26(2):194-199(in Chinese) doi: 10.3969/j.issn.1000-2758.2008.02.012 [9] Zhu K P, Yu X L. The monitoring of micro milling tool wear conditions by wear area estimation[J]. Mechanical Systems and Signal Processing, 2017, 93:80-91 doi: 10.1016/j.ymssp.2017.02.004 [10] 庞彦伟, 周俊, 邓君坪, 等.基于图像分解与字典分类的单幅图像去雨算法[J].天津大学学报, 2017, 50(4):391-398 http://d.old.wanfangdata.com.cn/Periodical/tianjdxxb201704008Pang Y W, Zhou J, Deng J P, et al. Single-Image rain removal algorithm based on image decomposition and dictionary classification[J]. Journal of Tianjin University, 2017, 50(4):391-398(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/tianjdxxb201704008 [11] Starck J L, Elad M, Donoho D L. Image decomposition via the combination of sparse representations and a variational approach[J]. IEEE Transactions on Image Processing, 2005, 14(10):1570-1582 doi: 10.1109/TIP.2005.852206 [12] 李映, 张艳宁, 许星.基于信号稀疏表示的形态成分分析:进展和展望[J].电子学报, 2009, 37(1):146-152 doi: 10.3321/j.issn:0372-2112.2009.01.026Li Y, Zhang Y N, Xu X. Advances and perspective on morphological component analysis based on sparse representation[J]. Acta Electronica Sinica, 2009, 37(1):146-152(in Chinese) doi: 10.3321/j.issn:0372-2112.2009.01.026 [13] 李林.基于Curvelet变换的SAR图像增强[J].仪器仪表学报, 2006, 27(S3):2134-2135 http://d.old.wanfangdata.com.cn/Periodical/yqyb2006z3146Li L. SAR image enhancement algorithm based on Curvelet transform[J]. Chinese Journal of Scientific Instrument, 2006, 27(S3):2134-2135(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/yqyb2006z3146 [14] 张业宏, 陈恩平, 么跃轩, 等.基于双边滤波与离散余弦变换的NLM去噪算法[J].燕山大学学报, 2018, 42(3):259-264 doi: 10.3969/j.issn.1007-791X.2018.03.011Zhang Y H, Chen E P, Me Y X, et al. NLM denoising algorithm based on bilateral filtering and discrete cosine transform[J]. Journal of Yanshan University, 2018, 42(3):259-264(in Chinese) doi: 10.3969/j.issn.1007-791X.2018.03.011 [15] 周艳青, 薛河儒, 潘新, 等.基于改进的Graph Cut算法的羊体图像分割[J].华中科技大学学报, 2018, 46(2):123-127 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hzlgdxxb201802023Zhou Y Q, Xue H R, Pan X, et al. Sheep image segmentation based on proposed Graph Cut algorithm[J]. Journal of Huazhong University of Science and Technology, 2018, 46(2):123-127(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hzlgdxxb201802023 [16] 高理文, 林小桦, 罗晓牧.结合简单交互和标记分水岭的复杂背景叶片图像分割方法[J].计算机应用与软件, 2016, 33(8):211-215 doi: 10.3969/j.issn.1000-386x.2016.08.047Gao L W, Lin X H, Luo X M. Segmentation method for leaf image under complex background combining simple man-machine interaction and marker-based watershed segmentation[J]. Computer Applications and Software, 2016, 33(8):211-215(in Chinese) doi: 10.3969/j.issn.1000-386x.2016.08.047 [17] Candès E, Demanet L, Donoho D, et al. Fast discrete Curvelet transform[J]. Multiscale Modeling & Simulation, 2006, 5(3):861-899 http://d.old.wanfangdata.com.cn/Periodical/zgtxtxxb-a201502008 -

下载:

下载: