|

[1]

|

Moghaddam S M, Sadeghi F. A review of microstructural alterations around nonmetallic inclusions in bearing steel during rolling contact fatigue[J]. Tribology Transactions, 2016, 59(6):1142-1156 doi: 10.1080/10402004.2016.1141447

|

|

[2]

|

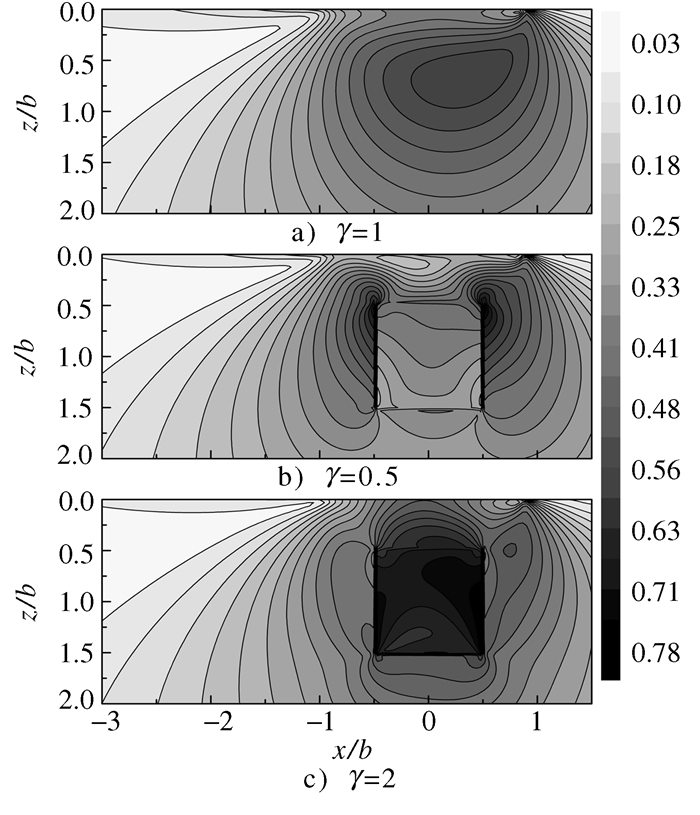

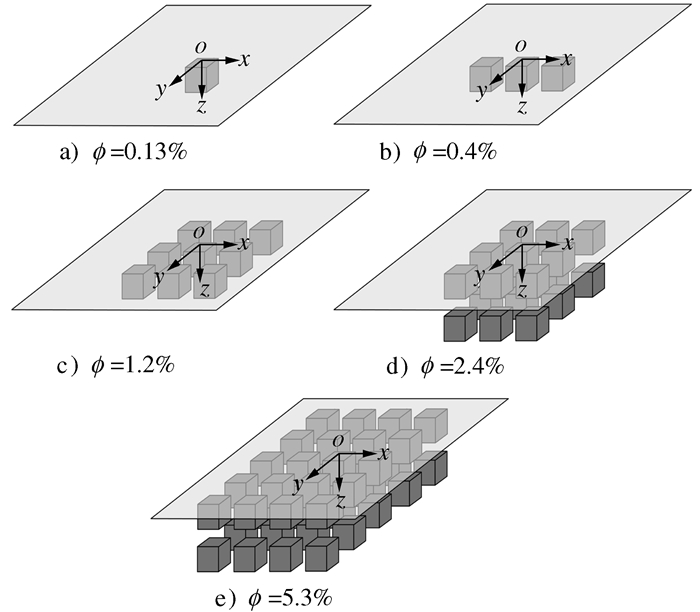

杨万友, 周青华, 王家序, 等.接触载荷作用下非均质材料表层应力集中分析[J].中南大学学报, 2018, 49(5):1095-1102 http://d.old.wanfangdata.com.cn/Periodical/zngydxxb201805010Yang W Y, Zhou Q H, Wang J X, et al. Subsurface stress concentration of heterogeneous material under contact loading[J]. Journal of Central South University, 2018, 49(5):1095-1102(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zngydxxb201805010

|

|

[3]

|

Eshelby J D. The determination of the elastic field of an ellipsoidal inclusion, and related problems[J]. Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, 1957, 241(1226):376-396 http://cn.bing.com/academic/profile?id=9b77a3d0b5eb0852dadebb762ad257aa&encoded=0&v=paper_preview&mkt=zh-cn

|

|

[4]

|

Zhou Q H, Xie L C, Jin X Q, et al. Numerical modeling of distributed inhomogeneities and their effect on rolling-contact fatigue life[J]. Journal of Tribology, 2015, 137(1):011402 doi: 10.1115/1.4028406

|

|

[5]

|

Zaretsky E Y. Fatigue criterion to system design, life, and reliability[J]. Journal of Propulsion and Power, 1987, 3(1):76-83 doi: 10.2514/3.22955

|

|

[6]

|

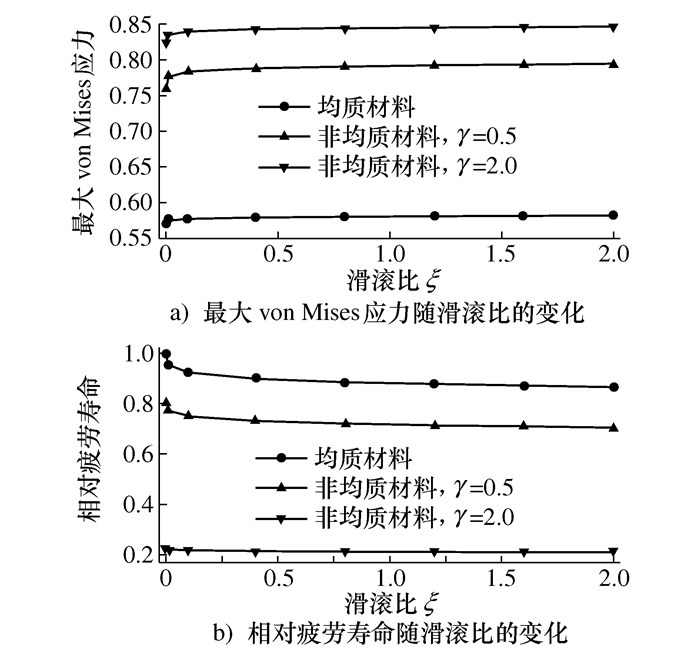

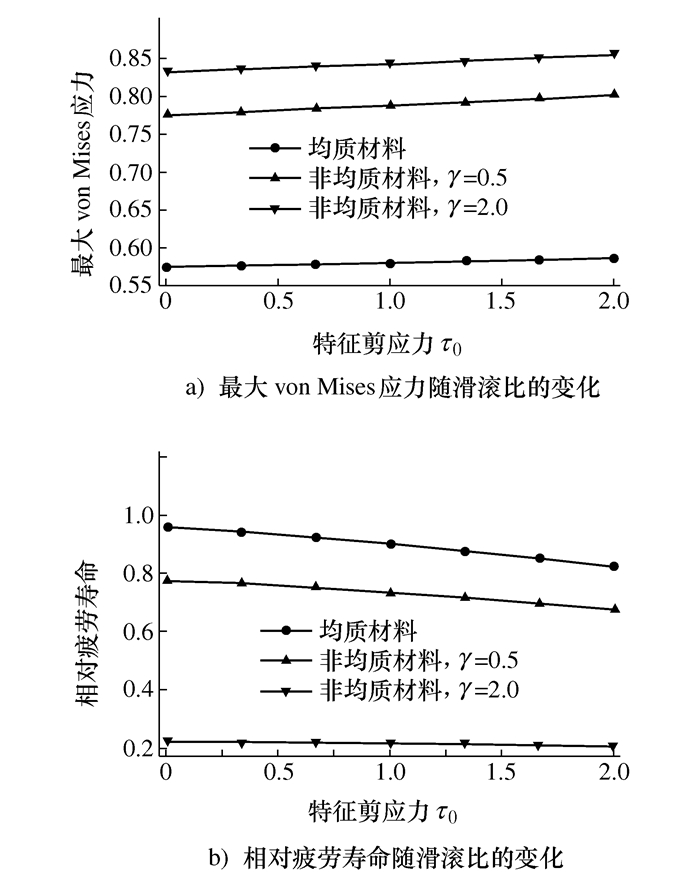

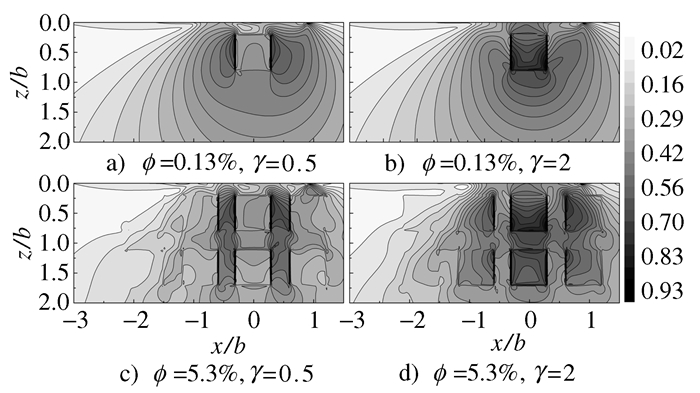

Yang W Y, Huang Y Y, Zhou Q H, et al. Parametric study on stressed volume and its application to the quantification of rolling contact fatigue performance of heterogeneous material[J]. Tribology International, 2017, 107:221-232 doi: 10.1016/j.triboint.2016.11.034

|

|

[7]

|

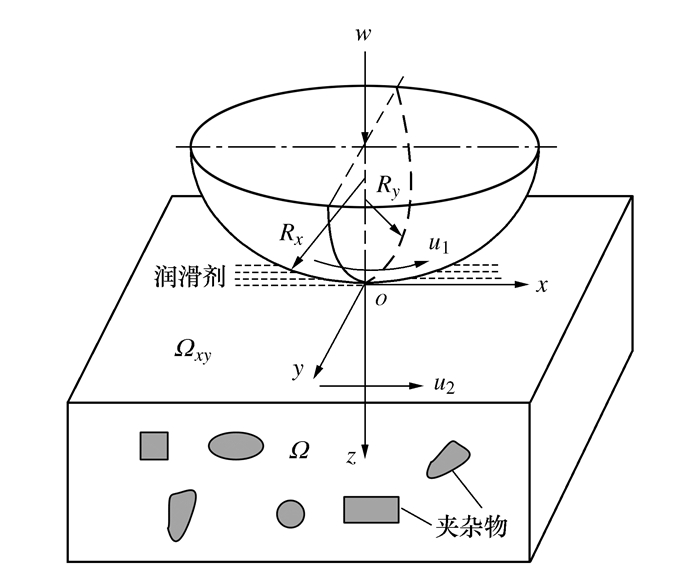

Wang Z J, Zhu D, Wang Q. Elastohydrodynamic lubrication of inhomogeneous materials using the equivalent inclusion method[J]. Journal of Tribology, 2014, 136(2):021501 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d9dca4513c838d1543bf0fadb644498c

|

|

[8]

|

Dong Q B, Zhou K. Numerical modeling of elastohydrodynamic lubrication in point or line contact for heterogeneous elasto-plastic materials[J]. Mechanics of Advanced Materials and Structures, 2017, 24(15):1300-1308 doi: 10.1080/15376494.2016.1227506

|

|

[9]

|

信召顺, 刘晓玲, 杨玉冰.圆柱滚子轴承的微观非牛顿热弹流润滑分析[J].润滑与密封, 2017, 42(11):43-48 doi: 10.3969/j.issn.0254-0150.2017.11.008Xin Z S, Liu X L, Yang Y B. Analysis of non-Newtonian thermal micro-EHL in cylindrical roller bearings[J]. Lubrication Engineering, 2017, 42(11):43-48(in Chinese) doi: 10.3969/j.issn.0254-0150.2017.11.008

|

|

[10]

|

Yan X L, Zhang Y Y, Xie G X, et al. Effects of texture orientation on the mixed thermal elastohydrodynamic lubrication and fatigue life in point contacts[J]. Journal of Tribology, 2019, 141(1):011501 http://cn.bing.com/academic/profile?id=946a0cadecfed427ae8f0ed0e737a93a&encoded=0&v=paper_preview&mkt=zh-cn

|

|

[11]

|

Dowson D, Higginson G R. Elastohydrodynamic lubrication:The fundamentals of roller and gear lubrication[M]. Oxford:Pergamon, 1966

|

|

[12]

|

Pu W, Zhu D, Wang J X, et al. Rolling-sliding contact fatigue of surfaces with sinusoidal roughness[J]. International Journal of Fatigue, 2016, 90:57-68 doi: 10.1016/j.ijfatigue.2016.04.007

|

|

[13]

|

Roelands C J A. Correlational aspects of the viscosity-temperature-pressure relationship of lubricating oils[D]. Netherlands: Delft University of Technology, 1966

|

|

[14]

|

Cui J, Yang P, Jin Z M, et al. Transient elastohydrodynamic analysis of elliptical contacts. Part 3:Non-Newtonian lubricant solution under isothermal and thermal conditions[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2007, 221(1):63-73 doi: 10.1243/13506501JET165

|

|

[15]

|

Wang Z J, Jin X Q, Zhou Q H, et al. An efficient numerical method with a parallel computational strategy for solving arbitrarily shaped inclusions in elastoplastic contact problems[J]. Journal of Tribology, 2013, 135(3):031401 doi: 10.1115/1.4023948

|

|

[16]

|

Zhou K, Chen W W, Keer L M, et al. Multiple 3D inhomogeneous inclusions in a half space under contact loading[J]. Mechanics of Materials, 2011, 43(8):444-457 doi: 10.1016/j.mechmat.2011.02.001

|

|

[17]

|

Yan X L, Wang X L, Zhang Y Y. A parametric study on fatigue life for mixed elastohydrodynamic lubrication point contacts[J]. Journal of Tribology, 2013, 135(4):041501 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e1e67d8db5ab50171905860e39f52d81

|

下载:

下载: