Study on Wear Model for Cutting Tools of Machinable Ceramic

-

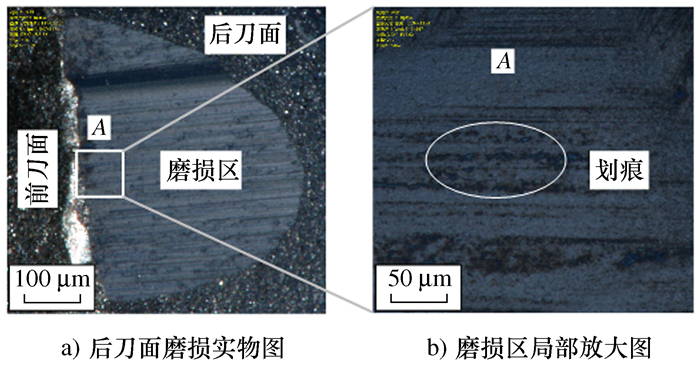

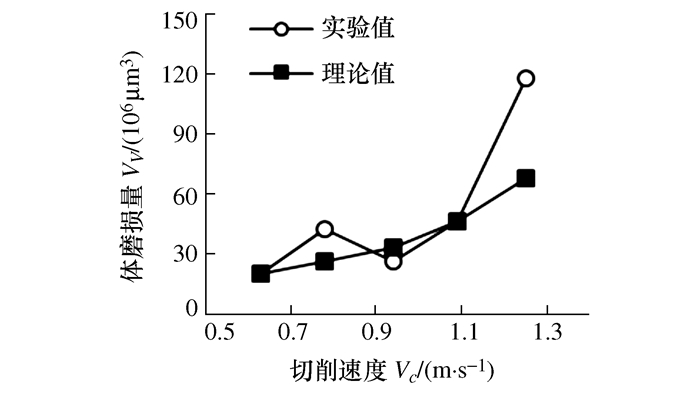

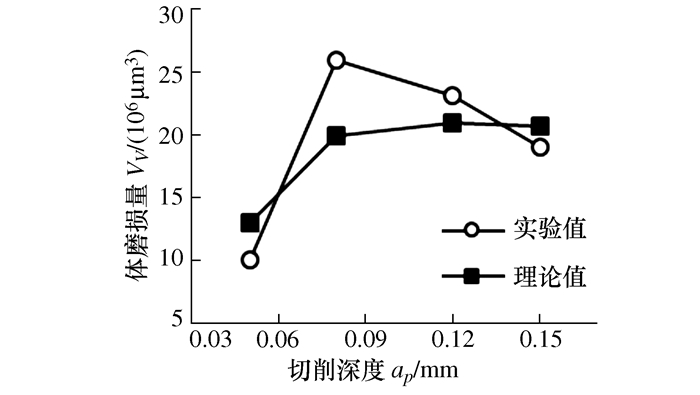

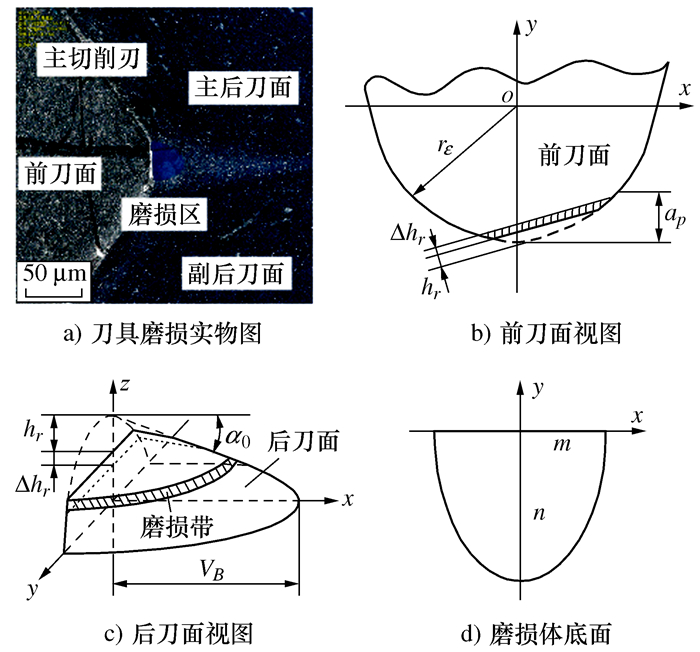

摘要: 使用硬质合金刀具对二硅酸锂玻璃陶瓷和氟金云母陶瓷进行车削实验,利用激光共聚焦检测系统观察刀具磨损形貌,研究刀具磨损机理。提出刀具磨损机制,即在工件待加工表面硬质点多次划擦作用下导致的疲劳磨损,刀具磨损形式为后刀面接触区的逐层剥落。通过赫兹接触理论和摩擦疲劳学建立了一种刀具磨损理论模型,而后在不同切削参数下进行车削实验,验证理论模型的有效性,分析切削参数对刀具磨损的影响。结果表明:理论模型计算值可以良好地预测刀具磨损量,模型预测曲线与实际磨损曲线趋势相符。Abstract: Using the cemented carbide tools to conduct the cutting experiments of Lithium disilicate glass ceramics and fluorophlogopite ceramics and the system of laser confocal detection to observe the wear profile, the wear mechanism of tool is investigated. The wear mechanism of tool is proposed, which is the fatigue wear caused by multiple scratches on the hard point of the workpiece. The wear form of tool is the layer-by-layer peeling of the flank contact area. A theoretical model for tool wear was established in terms of the Hertz contact theory and friction fatigue theory. Then the turning experiment was carried out under different cutting parameters to verify the validity of the model and analyze the influence of the cutting parameters on the tool wear. Finally, the results show that the calculated value via model can predict the tool wear greatly well, and the prediction curve via model is consistent with the actual wear curve.

-

Key words:

- model for tools wear /

- fatigue /

- machinable ceramics /

- cutting

-

表 1 工件材料综合性能

工件材料 密度ρ 硬度H(HRC) 断裂韧性ΚIC 最大颗粒半径R/μm 二硅酸锂 2.40 54.7 3.0 15 氟金云母 2.65 52.3 2.2 10 表 2 切削实验参数

工件材料 主轴转速n/(r·min-1) 进给量f/(mm·r-1) 切削深度ap/mm 切削长度H/mm 二硅酸锂 600 0.03 0.02 80~720 氟金云母 400~800 0.08 0.1 800 氟金云母 600 0.05~0.15 0.1 800 氟金云母 600 0.08 0.05~0.15 800 表 3 刀具性能参数

刀具材料 弹性模量E/GPa 泊松比υ 屈服强度σ/MPa 剪切强度τ/MPa 摩擦系数μ 硬质合金 620 0.23 1 600 85.3 0.4 -

[1] Khorasani A M, Gibson I, Goldberg M, et al. Machinability of metallic and ceramic biomaterials:a review[J]. Science of Advanced Materials, 2016, 8(8):1491-1511 [2] Singh R P, Singhal S. Investigation of machining characteristics in rotary ultrasonic machining of alumina ceramic[J]. Materials and Manufacturing Processes, 2016, 32(3):309-326 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1080/10426914.2016.1176190 [3] Abdo B M A, Anwar S, El-Tamimi A M, et al. Laser micro-milling of bio-lox forte ceramic:an experimental analysis[J]. Precision Engineering, 2018, 53:179-193 https://www.sciencedirect.com/science/article/pii/S0141635918301016 [4] Pachaury Y, Tandon P. An overview of electric discharge machining of ceramics and ceramic based composites[J]. Journal of Manufacturing Processes, 2017, 25:369-390 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=882e3e93803d5f4d6a1e1cc381a0173d [5] Li X, Li J Z, Yu Z Y, et al. Influences of pre-sintered ceramic compacts processing parameters on tool wear[J]. Advanced Materials Research, 2015, 1120-1121:32-37 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/AMR.1120-1121.32 [6] Zhan Z B, He N, Li L, et al. Precision milling of tungsten carbide with micro PCD milling tool[J]. The International Journal of Advanced Manufacturing Technology, 2015, 77(9-12):2095-2103 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=185a6171da7e978bc7723aa2488f8484 [7] Gao G F, Zhao B, Xiang D H, et al. Research on the force characteristics in ultrasonic grinding nano-zirconia ceramics[J]. Key Engineering Materials, 2008, 375-376:258-262 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/KEM.375-376.258 [8] Wang T, Xie L J, Wang X B, et al. PCD tool performance in high-speed milling of high volume fraction SiCp/Al composites[J]. The International Journal of Advanced Manufacturing Technology, 2015, 78(9-12):1445-1453 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=a09732cdae9732b764e909cb0397bc82 [9] 马廉洁, 谭福慧, 李德震, 等.车削加工陶瓷材料时刀具磨损表面形态的研究[J].工具技术, 2017, 51(5):26-28 http://d.old.wanfangdata.com.cn/Periodical/gjjs201705005Ma L J, Tan F H, Li D Z, et al. Study on surface morphology of tool wear in turning machinable ceramics[J]. Tool Engineering, 2017, 51(5):26-28(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gjjs201705005 [10] Bian R, He N, Ding W Z, et al. A study on the tool wear of PCD micro end mills in ductile milling of ZrO2 ceramics[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(5-8):2197-2206 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7adbe7d8f4f631c66f0d0836bb93a54d [11] Duan C Z, Sun W, Fu C, et al. Modeling and simulation of tool-chip interface friction in cutting Al/SiCp composites based on a three-phase friction model[J]. International Journal of Mechanical Sciences, 2018, 142-143:384-396 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0ca93b35ecd0eef1bd004fac10334f4b [12] Maruda R W, Krolczyk G M, Nieslony P, et al. The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism[J]. Journal of Manufacturing Processes, 2016, 24:107-115 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0af03a03122a50bb2ee796620c1a128c [13] Martinez I, Tanaka R, Yamane Y, et al. Wear mechanism of coated tools in the turning of ductile cast iron having wide range of tensile strength[J]. Precision Engineering, 2017, 47:46-53 https://www.sciencedirect.com/science/article/pii/S0141635916300940 [14] Pervaiz S, Samad W A. Tool wear mechanisms of physical vapor deposition (PVD) TiAlN coated tools under vegetable oil based lubrication[M]//Wang J L, Antoun B, Brown E, et al. Mechanics of Additive and Advanced Manufacturing, Volume 9. Cham: Springer, 2018: 101-107 [15] 瓦伦宁L.波波夫.接触力学与摩擦学的原理及其应用[M].李强, 雒建斌, 译.北京: 清华大学出版社, 2011: 46-60Valentin L. Contact mechanics and friction physical principles and applications[M]. Li Q, Luo J B, trans. Beijing: Tsinghua University Press, 2011: 46-60(in Chinese) [16] Hamilton G M. Explicit equations for the stresses beneath a sliding spherical contact[J]. Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science, 1983, 197(1):53-59 -

下载:

下载: