Non-Hertz Contact and Failure Mechanism Analysis of Ball Bearings with Deep Groove

-

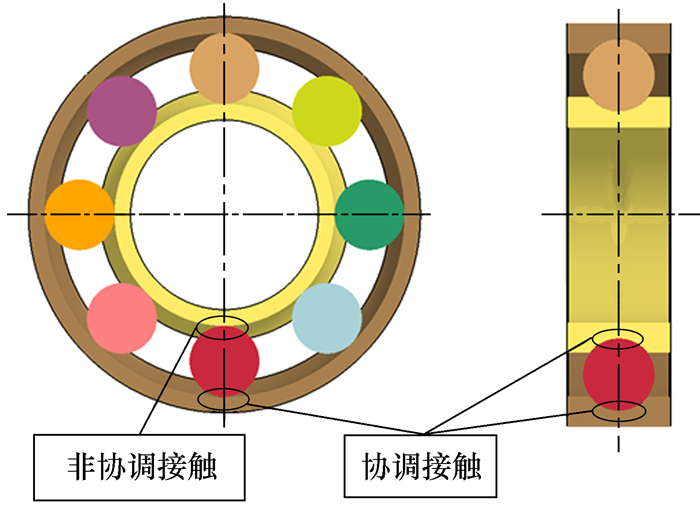

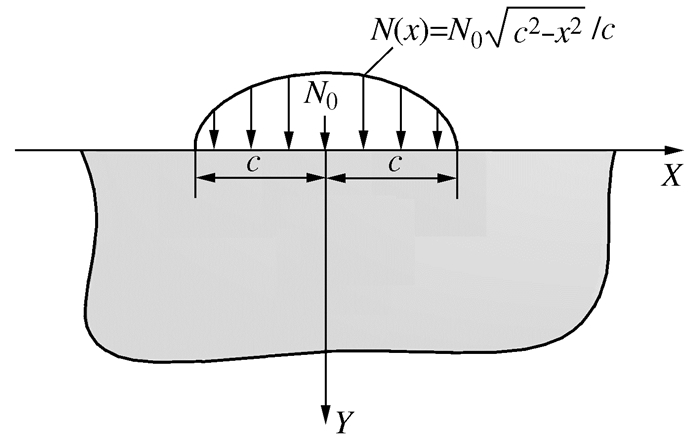

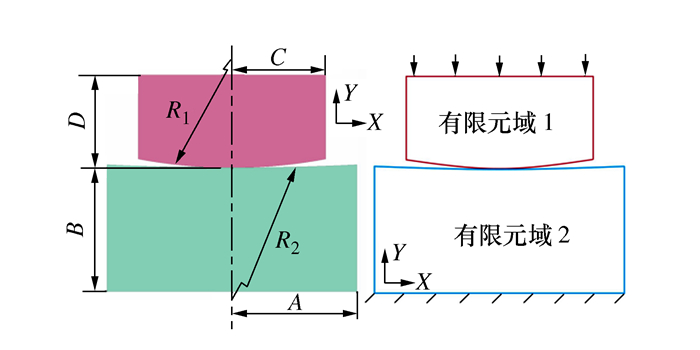

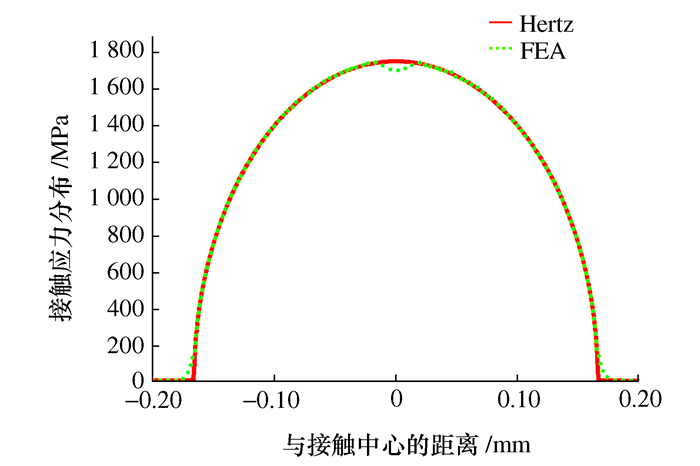

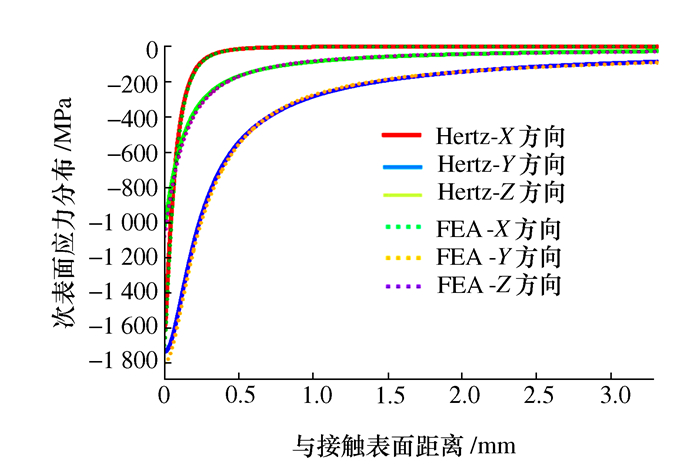

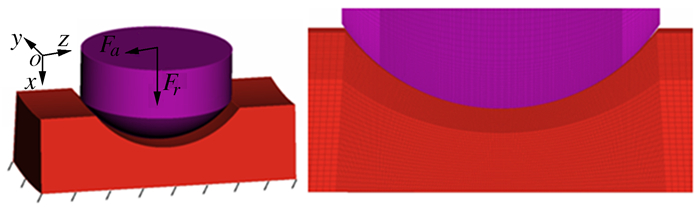

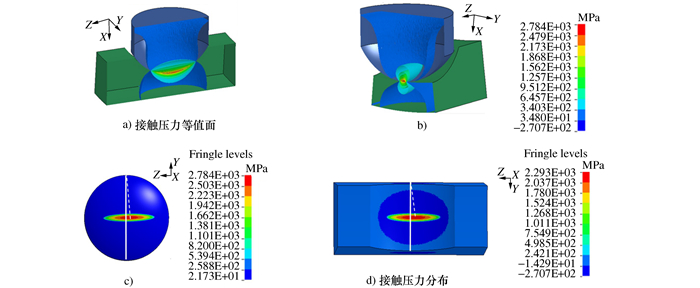

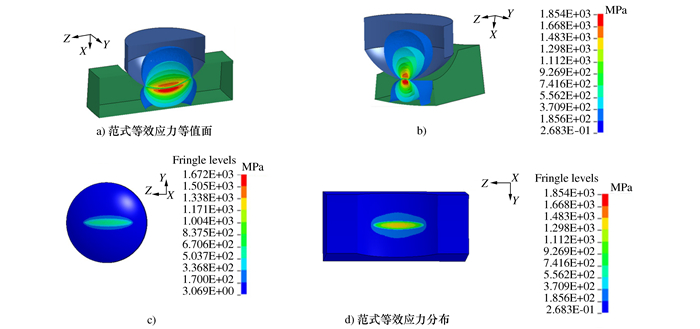

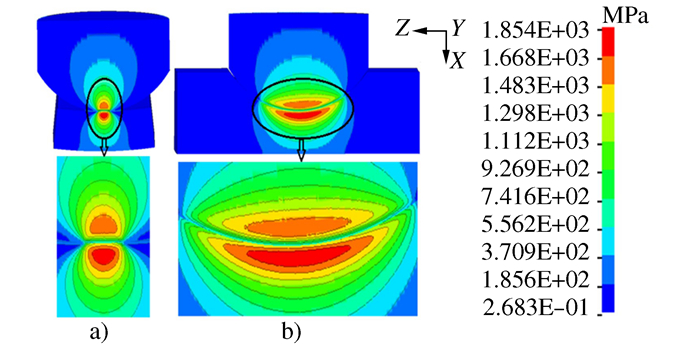

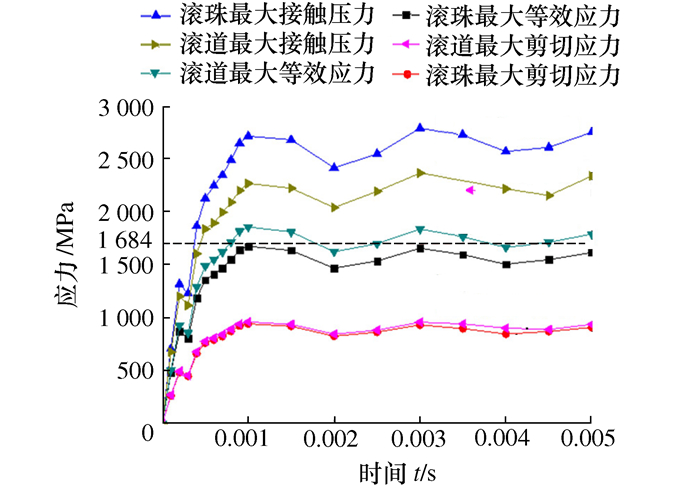

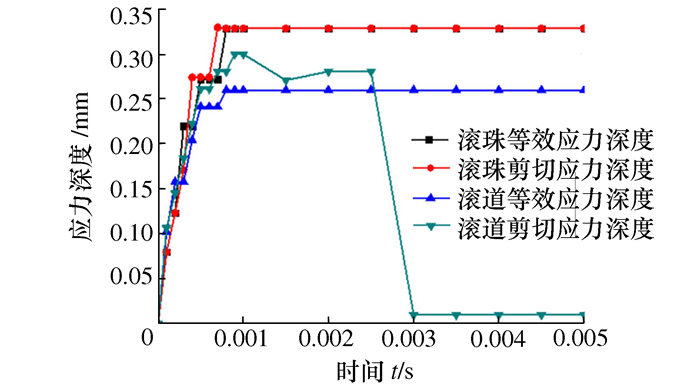

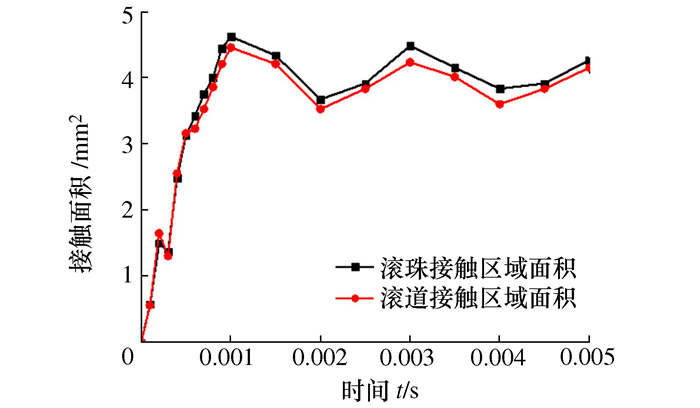

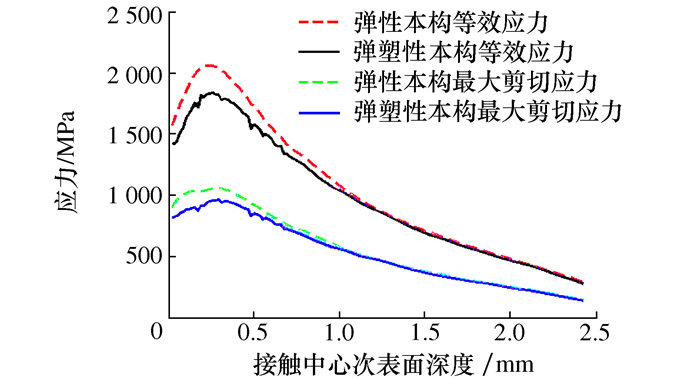

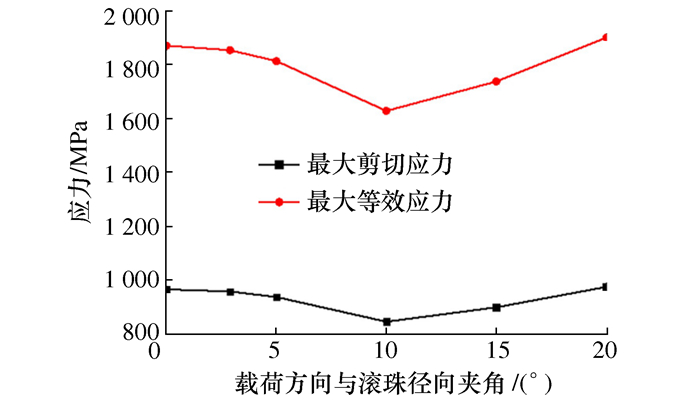

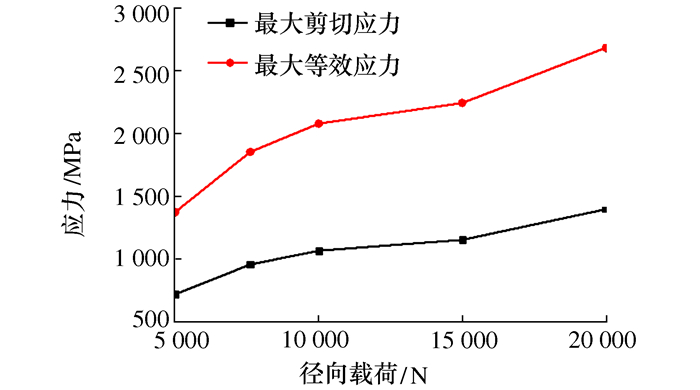

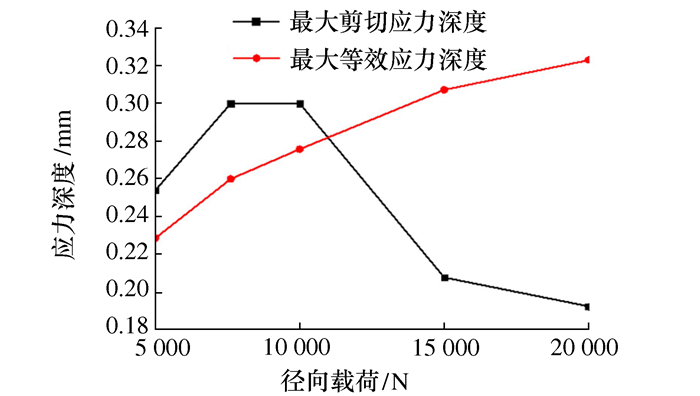

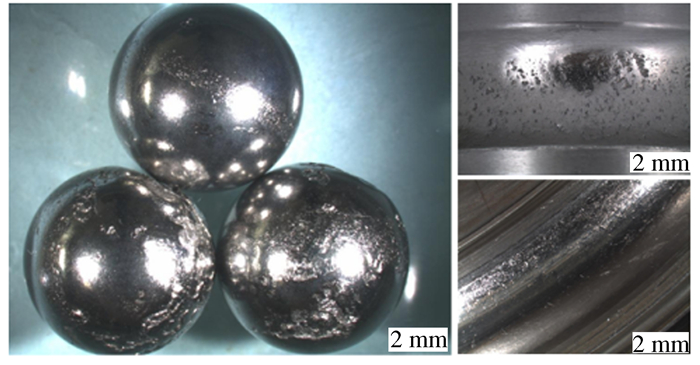

摘要: 考虑轴向载荷、弹塑性本构、协调接触、轴承游隙等因素的影响,对某汽车变速器中所采用的深沟球轴承在服役过程中出现的失效问题通过非赫兹有限元数值模型进行了求解,并据此分析了该轴承在工作过程中的失效机理。进一步研究了轴承材料本构、交变载荷等因素对接触状态的影响。结果表明:弹性本构承载体积小于弹塑性本构,应力水平高于弹塑性本构;载荷按一定角度作用可以降低轴承内部应力极值;载荷增加使应力极值和初始屈服深度增加,但当载荷过大时,初始屈服深度会急剧减小。Abstract: Considering the effects of the axial load, elasto-plastic constitutive, coordinated contact, bearing clearance and other factors, the failure of the ball bearing with deep groove used in an automotive transmission in the service process is solved by the non-Hertz finite element model. Based on the above-mentioned, the failure mechanism of the bearing in the servicing process is obtained. The effects of the constitutive model for bearing material and the alternating load on the contact state are further studied. The results show that the elastic constitutive model has a smaller bearing capacity than the elasto-plastic constitutive model, and the stress level is higher. The load can reduce the internal stress extreme value of the bearing at a certain angle. The stress extreme value and the initial yield depth increases with the increasing of load. But when the load is too large, the initial yield depth decreases sharply.

-

表 1 滚珠载荷分布

滚珠序号 径向力/N 轴向力/N 1 7 615.11 385.33 2 4 449.48 747.85 3 1 018.70 547.58 4 608.62 532.68 5 672.47 641.45 6 608.41 536.33 7 1 049.46 555.82 8 4 384.27 731.83 -

[1] 夏均忠, 刘远宏, 但佳璧, 等.基于EMD分形技术提取变速器轴承故障特征[J].噪声与振动控制, 2012, 32(2):119-122, 127 http://d.old.wanfangdata.com.cn/Periodical/zsyzdkz201202029Xia J Z, Liu Y H, Dan J B, et al. Extraction of transmission bearing fault characters based on EMD fractal technology[J]. Noise and Vibration Control, 2012, 32(2):119-122, 127(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zsyzdkz201202029 [2] 蔡源春.汽车变速器轴承故障诊断研究[D].长沙: 湖南大学, 2007 http://cdmd.cnki.com.cn/article/cdmd-10532-2007160566.htmCai Y C. Research of diagnosis on the fault of the rolling element bearing in transmission[D]. Changsha: Hunan University, 2007(in Chinese) http://cdmd.cnki.com.cn/article/cdmd-10532-2007160566.htm [3] Littmann W E. The mechanism of contact fatigue[M]//Ku P M. Interdisciplinary Approach to the Lubrication of Concentrated Contacts.; Washington DC: NASA, 1970: 309-378 [4] Olver A V. The mechanism of rolling contact fatigue:an update[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2005, 219(5):313-330 doi: 10.1243/135065005X9808 [5] Glodež S, Potočnik R, Flašker J. Computational model for calculation of static capacity and lifetime of large slewing bearing's raceway[J]. Mechanism and Machine Theory, 2012, 47:16-30 doi: 10.1016/j.mechmachtheory.2011.08.010 [6] Korolev A V, Korolev A A, Krehel' R. Character of distribution of the load between the balls in the ball bearings under the action combined of external load[J]. Mechanism and Machine Theory, 2014, 81:54-61 doi: 10.1016/j.mechmachtheory.2014.06.011 [7] El-Thalji I, Jantunen E. A descriptive model of wear evolution in rolling bearings[J]. Engineering Failure Analysis, 2014, 45:204-224 doi: 10.1016/j.engfailanal.2014.06.004 [8] Hertz H. Uber Die Berührung fester elastischer Ko··rper[J]. Journal für die Reine und Angewandte Mathematik (Crelle's Journal), 2009, 1882(92):156-171 [9] Johnson K L. Contact mechanics[M]. Cambridge:University of Cambridge, 1985 [10] Arregui I L, Alfredsson B. Elastic-plastic characterization of a high strength bainitic roller bearing steel-experiments and modelling[J]. International Journal of Mechanical Sciences, 2010, 52(10):1254-1268 doi: 10.1016/j.ijmecsci.2010.06.001 [11] Goodman L E, Keer L M. The contact stress problem for an elastic sphere indenting an elastic cavity[J]. International Journal of Solids and Structures, 1965, 1(4):407-415 doi: 10.1016/0020-7683(65)90005-3 [12] Kang Y, Shen P C, Huang C C, et al. A modification of the Jones-Harris method for deep-groove ball bearings[J]. Tribology International, 2006, 39(11):1413-1420 doi: 10.1016/j.triboint.2005.12.005 [13] Zhupanska O I. Contact problem for elastic spheres:applicability of the Hertz theory to non-small contact areas[J]. International Journal of Engineering Science, 2011, 49(7):576-588 doi: 10.1016/j.ijengsci.2011.02.003 [14] 吴飞科, 罗继伟, 张磊, 等.关于Hertz点接触理论适用范围的探讨[J].轴承, 2007(5):1-3 doi: 10.3969/j.issn.1000-3762.2007.05.001Wu F K, Luo J W, Zhang L, et al. Discussion on application limit to Hertz's contact theory[J]. Bearing, 2007(5):1-3(in Chinese) doi: 10.3969/j.issn.1000-3762.2007.05.001 [15] 高霁, 苏新伟, 钟佳丽.Hertz理论在球轴承应用方面的局限性[J].轴承, 2008(11):9-11 doi: 10.3969/j.issn.1000-3762.2008.11.003Gao J, Su X W, Zhong J L. Application limitations of hertz's theory in ball bearings[J]. Bearing, 2008(11):9-11(in Chinese) doi: 10.3969/j.issn.1000-3762.2008.11.003 [16] Jin X Q. Analysis of some two dimensional problems containing cracks and holes[D]. Chicago: Northwestern University, 2006: 11 [17] 兰江明.某变速器轴承滚珠与滚道非赫兹接触分析[D].重庆: 重庆大学, 2015 http://cdmd.cnki.com.cn/Article/CDMD-10611-1015967331.htmLan J M. A non-Hertzian contact analysis for the ball and raceway of a transmission bearing[D]. Chongqing: Chongqing University, 2015(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10611-1015967331.htm [18] Stribeck R. Ball bearing for various loads[J]. Transactions of ASME, 1907, 29:420-463 [19] Sjovall H. The load distribution within ball and roller bearings under given external radial and axial load[J]. Teknisk Tidskrift, 1933, 19(3):72-75 [20] Lundberg G, Palmgren A. Dynamic capacity of rolling bearings[J]. Acta Polytechnica Scandinavica. Mechanical Engineering Series, 1947, 1(3):7 -

下载:

下载: