Study on Process Damping and Cutting Stability in Combined Turn-milling Machining

-

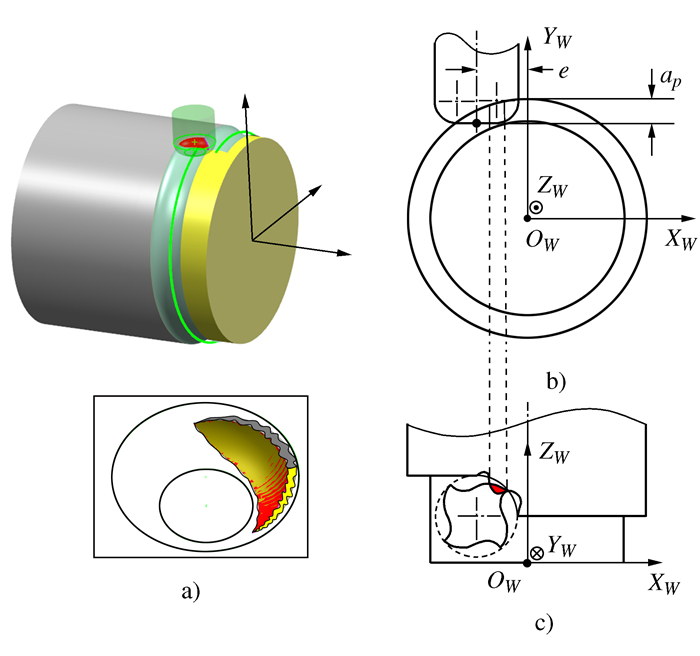

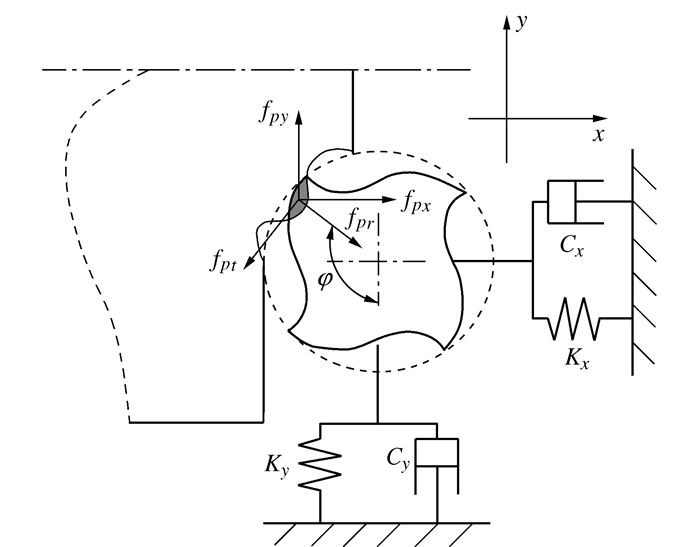

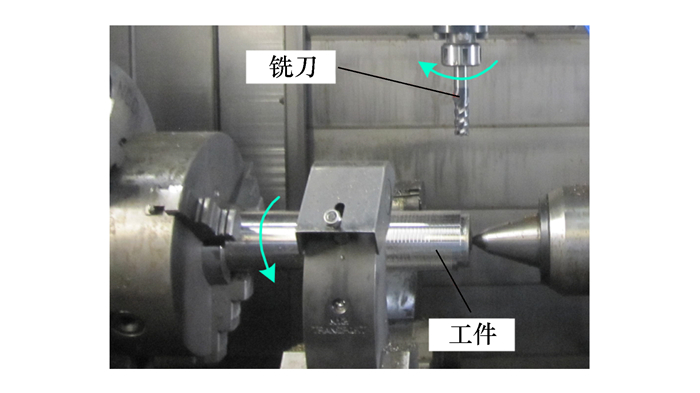

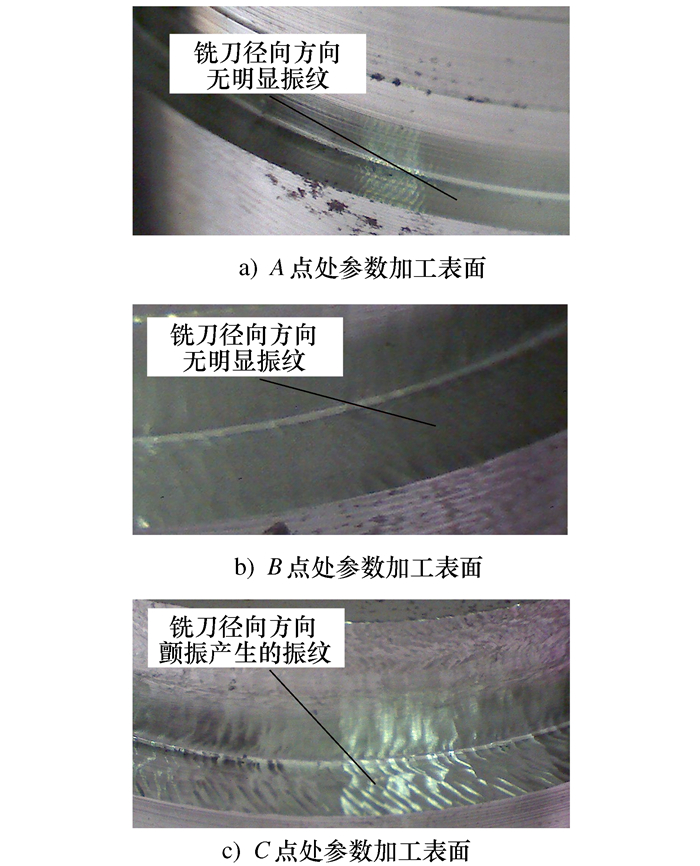

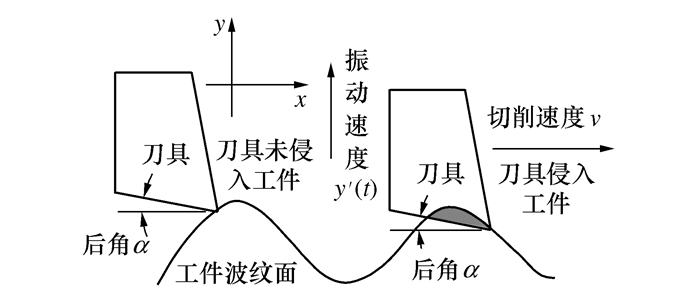

摘要: 车铣复合加工具有一次装夹多工序加工、加工表面温度低及刀具磨损小等优势,非常适用于起落架等复杂回转类零件的加工。加工稳定性分析是进行参数优选、避免加工颤振的有效方法,在低速车铣复合加工过程中,过程阻尼会对稳定性边界产生显著影响。本文中分析了车铣复合加工过程阻尼的产生机理,建立了等效过程阻尼模型;在车铣复合加工动力学方程中引入过程阻尼,实现了考虑过程阻尼的车铣复合加工稳定性预测,得到低速切削区域的精确稳定性边界;并分析了过程阻尼对稳定性边界的影响规律,最后利用车铣加工切削实验验证了本文提出的考虑过程阻尼的稳定性预测模型的正确性。研究结果表明,过程阻尼会提高稳定性边界,且随着切削速度的降低提升作用愈发明显。Abstract: The turn-milling combined machining has the advantages of one-time multi-step machining, low surface temperature and small tool wear, which is very suitable for machining complex rotary parts such as landing gear. Machining stability analysis is an effective method to optimize parameters and avoid machining flutter. In low-speed turn-milling combined process, process damping has a significant influence on stability boundary. In this paper, the mechanism of damping in the turn-milling machining is analyzed. The equivalent process damping model is established. The process damping is introduced into the dynamic equation of turn-milling. The stability prediction in turn-milling combined machining considering process damping is realized. The precise stability boundary of the cutting area is analyzed, and the influence of the process damping on the stability boundary is analyzed. Finally, the prediction model for stability considering the process damping is verified by using the milling experiment. The results show that the process damping will increase the stability boundary, and the effect will increase as the cutting speed decreases.

-

Key words:

- turn-milling machining /

- process damping /

- machining dynamics /

- stability boundary

-

表 1 刀具端模态参数

方向 频率/Hz 阻尼比 留数 x 1291 0.06 7.24×10-5-3.11×10-4i y 1274 0.05 8.11×10 -5-2.66×10-4i -

[1] 唐小卫.大型轴类零件车铣加工稳定性研究与应用[D].武汉: 华中科技大学, 2017 http://cdmd.cnki.com.cn/Article/CDMD-10487-1017128561.htmTang X W. Stability research and applications on turn-milling of large-sized shaft parts[D]. Wuhan: Huazhong University of Science and Technology, 2017(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10487-1017128561.htm [2] 徐嘉伟.起落架外筒典型特征加工工艺优化及软件开发[D].武汉: 华中科技大学, 2017 http://cdmd.cnki.com.cn/Article/CDMD-10487-1018970290.htmXu J W. Machining processes optimization for typical features of landing gear sleeve and software development[D]. Wuhan: Huazhong University of Science and Technology, 2017(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10487-1018970290.htm [3] Uysal E, Karaguzel U, Budak E, et al. Investigating eccentricity effects in turn-milling operations[J]. Procedia CIRP, 2014, 14:176-181 doi: 10.1016/j.procir.2014.03.042 [4] Karagüzel U, Uysal E, Budak E, et al. Analytical modeling of turn-milling process geometry, kinematics and mechanics[J]. International Journal of Machine Tools and Manufacture, 2015, 91:24-33 doi: 10.1016/j.ijmachtools.2014.11.014 [5] Filho J M C. Prediction of cutting forces in mill turning through process simulation using a five-axis machining center[J]. The International Journal of Advanced Manufacturing Technology, 2012, 58(1-4):71-80 doi: 10.1007/s00170-011-3391-6 [6] 汪勇.轴类零件正交车铣加工稳定性建模与分析[D].武汉: 华中科技大学, 2014 http://cdmd.cnki.com.cn/Article/CDMD-10487-1015010300.htmWang Yong. Stability modeling and analysis for orthogonal turn-milling of shaft parts[D]. Wuhan: Huazhong University of Science and Technology, 2014(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10487-1015010300.htm [7] Guan Y Q, Guan H Q, Wang G S, et al. Modeling and emulation of 3D dither stability in orthogonal turn-milling[J]. International Journal of Hybrid Information Technology, 2016, 9(6):231-244 doi: 10.14257/ijhit.2016.9.6.20 [8] Comak A, Altintas Y. Dynamics and stability of turn-milling operations with varying time delay in discrete time domain[J]. Journal of Manufacturing Science and Engineering, 2018, 140(10):101013 doi: 10.1115/1.4040726 [9] Karaguzel U, Uysal E, Budak E, et al. Effects of tool axis offset in turn-milling process[J]. Journal of Materials Processing Technology, 2016, 231:239-247 doi: 10.1016/j.jmatprotec.2015.12.020 [10] Tlusty J, Ismail F. Special aspects of chatter in milling[J]. Journal of Vibration, Acoustics, Stress, and Reliability in Design, 1983, 105(1):24-32 doi: 10.1115/1.3269061 [11] Ahmadi K, Ismail F. Analytical stability lobes including nonlinear process damping effect on machining chatter[J]. International Journal of Machine Tools and Manufacture, 2011, 51(4):296-308 doi: 10.1016/j.ijmachtools.2010.12.008 [12] Eynian M, Altintas Y. Chatter stability of general turning operations with process damping[J]. Journal of Manufacturing Science and Engineering, 2009, 131(4):041005 doi: 10.1115/1.3159047 [13] Ahmadi K, Altintas Y. Identification of machining process damping using output-only modal analysis[J]. Journal of Manufacturing Science and Engineering, 2014, 136(5):051017 doi: 10.1115/1.4027676 [14] Wan M, Feng J, Ma Y C, et al. Identification of milling process damping using operational modal analysis[J]. International Journal of Machine Tools and Manufacture, 2017, 122:120-131 doi: 10.1016/j.ijmachtools.2017.06.006 [15] Chiou R Y, Liang S Y. Chatter stability of a slender cutting tool in turning with tool wear effect[J]. International Journal of Machine Tools and Manufacture, 1998, 38(4):315-327 doi: 10.1016/S0890-6955(97)00079-5 -

下载:

下载: