Investigation of Cutting Heat of Interface in Helical Milling of Titanium and Carbon Fiber Reinforced Plastic Stack

-

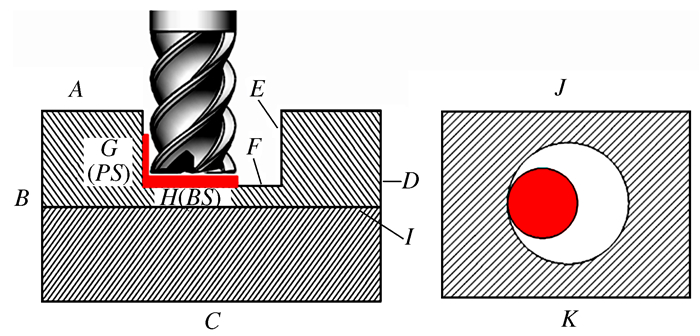

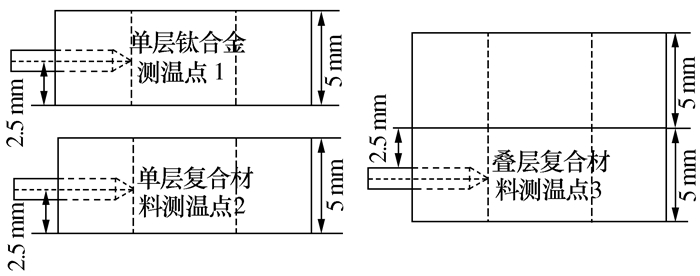

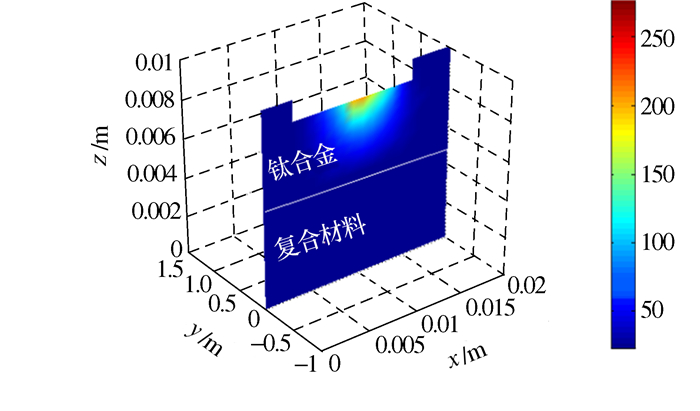

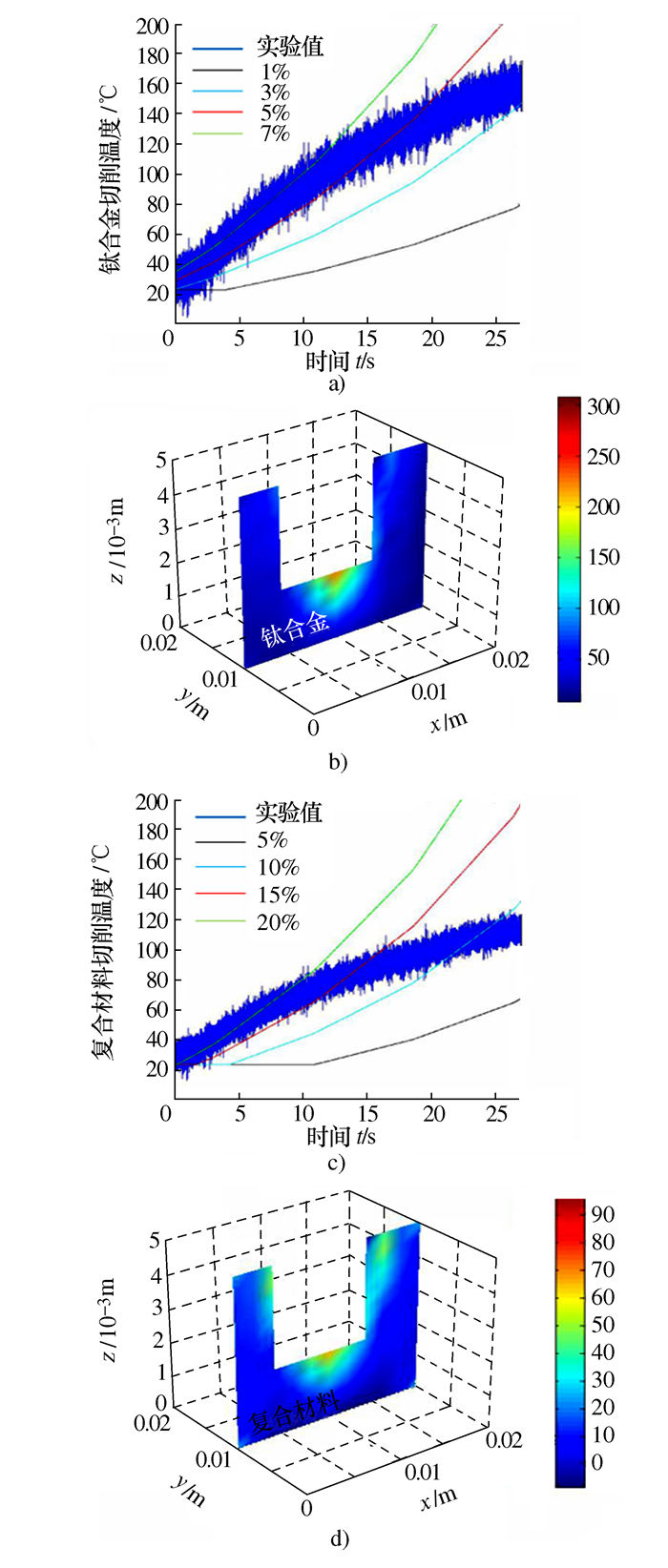

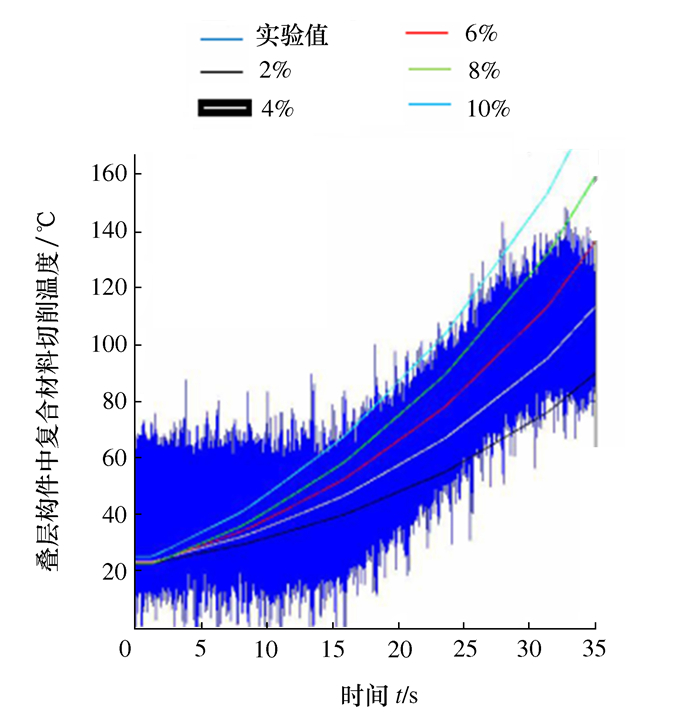

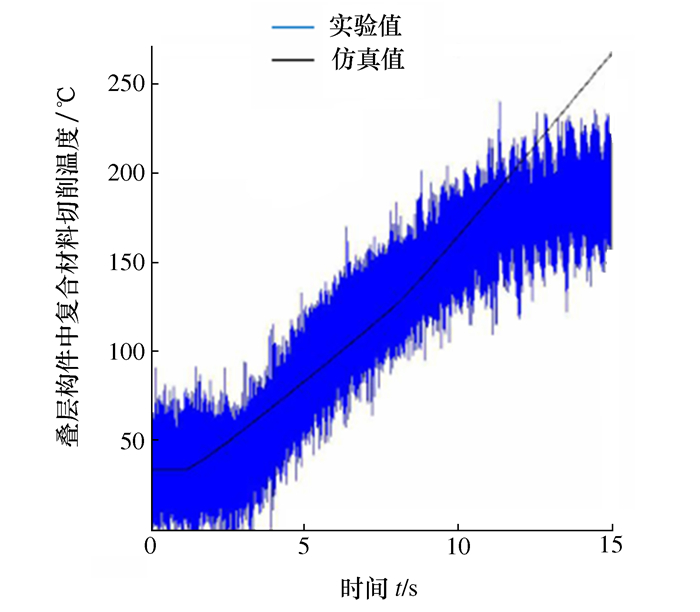

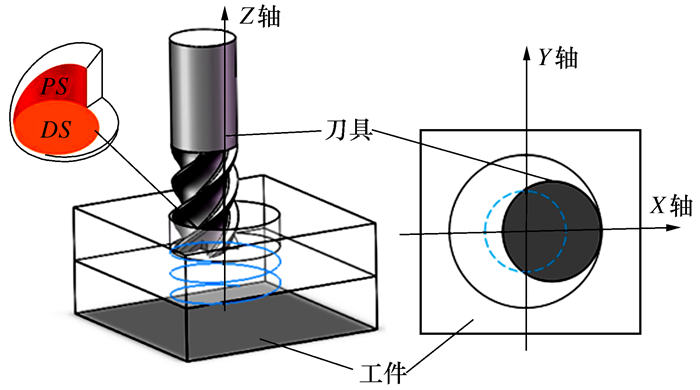

摘要: 随着钛合金和复合材料(Carbon fiber reinforced plastic,CFRP)在航空航天制造业的应用比例逐渐增多,其叠层构件切削加工也成为研究热点。由于切削温度不仅影响刀具的磨损和耐用度,同时也会直接影响工件的加工精度和表面质量,本文在分析螺旋铣孔特点的基础上,对钛合金/CFRP叠层构件界面热传递机理进行了研究,建立了钛合金/CFRP叠层构件界面热传递模型,通过有限差分法对模型进行数值仿真求解;结合钛合金/CFRP螺旋铣孔实验,修正了刀具与工件的热传递系数以及工件界面温度传导率,通过钛合金/CFRP叠层构件螺旋铣孔切削热理论模型与试验结果对比,发现本文提出的理论模型分析结果和实验测量结果具有较高的一致性,能为钛合金/CFRP叠层螺旋铣孔加工工艺优化提供理论依据。Abstract: With the increasing proportion of titanium alloys and carbon fiber reinforced plastics (CFRP) in aerospace manufacturing, the cutting of laminated components has become a research hotspot. Since the cutting temperature not only affects the wear and durability of the tool, but also directly affects the machining accuracy of the workpieces and the quality of the machined surface. Based on the principle of helical milling, the mechanism of interface heat transfer in drilling titanium alloy/composite is studied. The interface model for titanium alloy/composite stacks is established. The model is calculated with computer simulation. The titanium alloy/composite experiment was carried out, and the heat transfer coefficient between the tool and the workpiece and interface heat transfer coefficient were corrected and verified via experimental data. By comparing the thermal theory and the experimental results in helical milling of titanium alloy/CFRP stacks, the analysis results and experimental data presented in this paper high consistency, which can provide a theoretical basis for studying helical milling cutting heat in titanium alloy/composite materials stacks.

-

表 1 T300单向复合材料和Ti6Al4V的热物性参数

材料 导热系数/[W·(m·K)-1] 比热容/[J·(kg·K)-1] 密度/(g·cm-3) T300/4221 k1=4.5, k2=k3=1.5 465 1 500 Ti-6Al-4V k=6.7 678 4 450 表 2 螺旋铣孔切削条件

设备 参数 机床 Hanland XK714D NCPC 工件材料 CFRP (T300 5 mm厚)钛合金(Ti6Al4V 5 mm厚) 刀具 螺旋铣孔4齿专用刀具 温度测量 K型热电偶 表 3 轴向力与扭矩实验数据(平均值)

材料 扭矩/(N·m) 轴向力/N T300单向复合材料 4.112 3 57.23 钛合金 15.76 125 -

[1] Shyha I S, Soo S L, Aspinwall D K, et al. Hole quality assessment following drilling of metallic-composite stacks[J]. International Journal of Machine Tools and Manufacture, 2011, 51(7-8):569-578 doi: 10.1016/j.ijmachtools.2011.04.007 [2] Xu J Y, Mkaddem A, El Mansori M. Recent advances in drilling hybrid FRP/Ti composite:a state-of-the-art review[J]. Composite Structures, 2016, 135:316-338 doi: 10.1016/j.compstruct.2015.09.028 [3] Brinksmeier E, Janssen R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys[J]. CIRP Annals, 2002, 51(1):87-90 doi: 10.1016/S0007-8506(07)61472-3 [4] Brinksmeier E, Fangmann S, Rentsch R. Drilling of composites and resulting surface integrity[J]. CIRP Annals, 2011, 60(1):57-60 doi: 10.1016/j.cirp.2011.03.077 [5] Kim D, Ramulu M. Study on the drilling of titanium/graphite hybrid composites[J]. Journal of Engineering Materials and Technology, 2007, 129(3):390-396 doi: 10.1115/1.2744397 [6] Kuo C L, Soo S L, Aspinwall D K, et al. The effect of cutting speed and feed rate on hole surface integrity in single-shot drilling of metallic-composite stacks[J]. Procedia CIRP, 2014, 13:405-410 doi: 10.1016/j.procir.2014.04.069 [7] Wang X, Kwon P Y, Sturtevant C, et al. Comparative tool wear study based on drilling experiments on CFRP/Ti stack and its individual layers[J]. Wear, 2014, 317(1-2):265-276 doi: 10.1016/j.wear.2014.05.007 [8] Wang B, Gao H, Cao B, et al. Mechanism of damage generation during drilling of carbon/epoxy composites and titanium alloy stacks[J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture, 2014, 228(7):698-706 doi: 10.1177/0954405413508117 [9] Wang C Y, Chen Y H, An Q L, et al. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill[J]. International Journal of Precision Engineering and Manufacturing, 2015, 16(8):1689-1697 doi: 10.1007/s12541-015-0222-y [10] Ramulu M, Branson T, Kim D. A study on the drilling of composite and titanium stacks[J]. Composite Structures, 2001, 54(1):67-77 doi: 10.1016/S0263-8223(01)00071-X [11] Denkena B, Boehnke D, Dege J H. Helical milling of CFRP-titanium layer compounds[J]. CIRP Journal of Manufacturing Science and Technology, 2008, 1(2):64-69 doi: 10.1016/j.cirpj.2008.09.009 [12] Brinksmeier E, Fangmann S. Burr and cap formation by orbital drilling of aluminum[C]//Proceedings of the CIRP International Conference on burrs-Analysis, Control and Removal. University of Kaiserslautern, Germany: Springer, 2009: 31-45 [13] 王振国, 于随然.碳纤维增强复合材料/钛合金叠层变参数钻削试验[J].机械设计与研究, 2017, 33(1):114-117, 126 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxsjyyj201701025Wang Z G, Yu S R. The experiment research on drilling of CFRP/titanium alloy stack with varying parameters[J]. Machine Design and Research, 2017, 33(1):114-117, 126(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxsjyyj201701025 [14] Montoya M, Calamaz M, Gehin D, et al. Numerical simulation of workpiece thermal field in drilling CFRP/Aluminum alloy[J]. Key Engineering Materials, 2014, 611-612:1226-1235 doi: 10.4028/www.scientific.net/KEM.611-612.1226 [15] Liu J, Chen G, Ji C H, et al. An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP)[J]. International Journal of Machine Tools and Manufacture, 2014, 86:89-103 doi: 10.1016/j.ijmachtools.2014.06.008 [16] Liu J, Ren C Z, Qin X D, et al. Prediction of heat transfer process in helical milling[J]. The International Journal of Advanced Manufacturing Technology, 2014, 72(5-8):693-705 doi: 10.1007/s00170-014-5662-5 [17] Brinksmeier E, Fangmann S, Meyer I. Orbital drilling kinematics[J]. Production Engineering, 2008, 2(3):277-283 doi: 10.1007/s11740-008-0111-7 [18] Zhu G P, Bao Y J, Gao H. Research on the drilling temperature field model of the unidirectional carbon fiber epoxy composites[J]. Advanced Materials Research, 2012, 565:478-483 doi: 10.4028/www.scientific.net/AMR.565.478 [19] 杨世铭, 陶文铨.传热学[M].北京:高等教育出版社, 2006:44-45Yang S M, Tao W S. Heat transfer[M]. Beijing:Higher Education Press, 2006(in Chinese) [20] 沈蓉影.碳纤维复合材料导热系数研究[J].材料工程, 1993(3):4-5 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000005157735Shen R Y. Study on thermal conductivity of carbon fiber composites[J]. Journal of Materials Engineering, 1993(3):4-5(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000005157735 -

下载:

下载: