Exploring Dynamic Cutting Process of Shearer's Drum

-

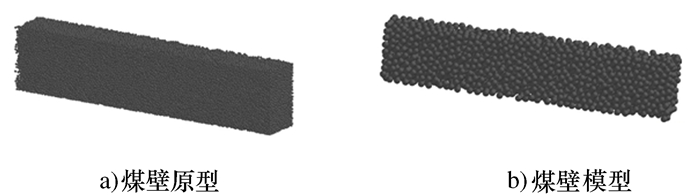

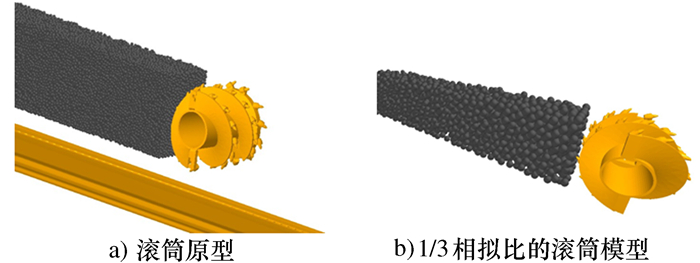

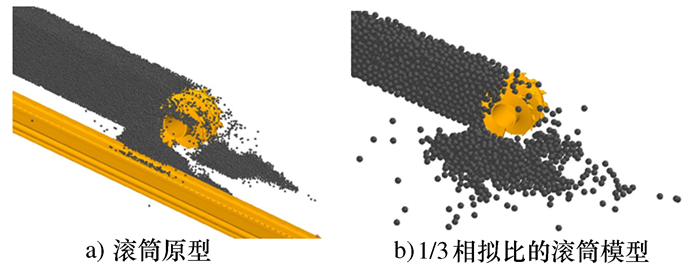

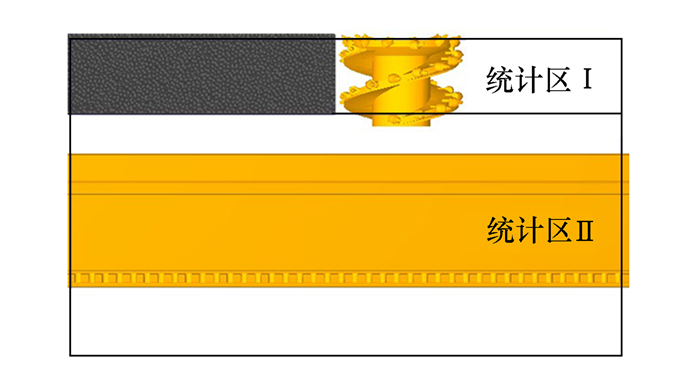

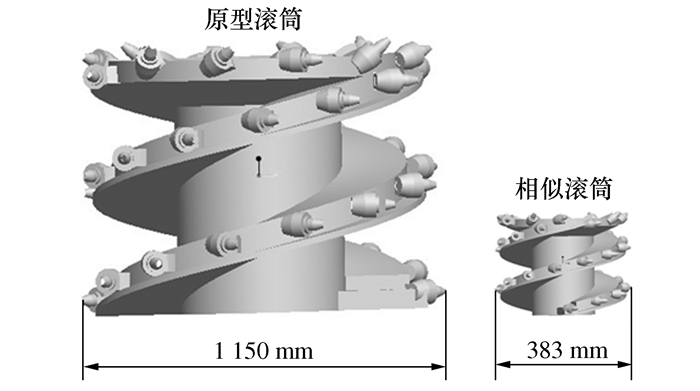

摘要: 为研究采煤机螺旋滚筒动态截割过程动力传递规律,基于相似理论建立螺旋滚筒模型与原型的相似准则,确定了模拟螺旋滚筒结构参数、运动学参数及截割材料特性参数,应用三维实体建模软件Pro/E、离散元分析软件EDEM联合仿真分析验证原型滚筒和模型滚筒动态截割过程中煤颗粒运动轨迹、量变规律、滚筒装煤率、滚筒载荷等性能。验证结果表明:原型滚筒和模型滚筒在截割过程中煤颗粒流动轨迹一致,截落的煤分布规律相似,载荷波动规律一致,滚筒装煤率预测误差1.82%,载荷数值误差小于2.1%,装煤率和载荷均值均满足推导的相似关系,验证了螺旋滚筒相似准则正确性。Abstract: In order to study the dynamic cutting processes and coal power transfer laws of a shearer's drum, its model drum was built based on the similarity theory; the prototype was similar to the parameters of similarity criterion. The structural parameters, movement parameters and cutting material characteristics of the drum to be simulated are determined. The Pro/E and EDEM were applied. The simulation analysis and verification of the prototype drum, the dynamic cutting process, coal particles' motion trail, quantitative change rule, coal rate and drum loading are the same. The cylinder model validation results show that the prototype drum's coal particle distributions are similar in the cutting process; the drum's coal rate prediction error is 1.82%; the loading error is less than 2.1%; the coal rate and loading are satisfactory, verifying the accuracy of the drum's similarity criterion.

-

Key words:

- shearer's drum /

- similarity theory /

- dynamic cutting process /

- discrete element method /

- coaling rate

-

表 1 滚筒相关参数量纲

参数 符号 量纲 滚筒直径/mm D M0L1T0 螺旋叶片头数/个 Z M0L0T0 每条截线截齿数/个 m M0L0T0 叶片螺旋升角/(°) α M0L0T0 滚筒转速/(r·min-1) n M0L0T-1 牵引速度/(m·min-1) vq M0L1T-1 煤的密度/(kg·m-3) ρ M1L-3T0 齿体屈服强度/MPa σ M1L-1T-2 重力加速度/(m·s-2) g M0L1T-2 滚筒所受载荷/N F M1L1T-2 装煤率/% Q M0L0T0 表 2 量纲矩阵指数表

参数 D n vq ρ σ g F 指数 a1 a2 a3 a4 a5 a6 a7 M 0 0 0 1 1 0 1 L 1 0 1 -3 -1 1 1 T 0 -1 -1 0 -2 -2 -2 表 3 滚筒主要参数π矩阵

参数 D n vq ρ σ g F 指数 a1 a2 a3 a4 a5 a6 a7 π1 1 0 0 0 1/2 0 -1/2 π2 0 1 0 0 -1/4 -1/2 1/4 π3 0 0 1 0 1/4 -1/2 -1/4 π4 0 0 0 1 -3/2 1 1/2 表 4 滚筒相关参数相似系数

参数 原型 模型 滚筒直径/mm D D/3 螺旋叶片头数/个 Z Z 每条截线截齿数/个 m m 叶片螺旋升角/(°) α α 滚筒转速/(r·min-1) n

牵引速度/(m·min-1) vq

煤的密度/(kg·m-3) ρ ρ 齿体屈服强度/MPa σ σ/3 重力加速度/(m·s-2) g g 滚筒所受载荷/N F F/27 装煤率/% Q Q 表 5 滚筒主要结构参数

参数 原型 模型 滚筒直径/mm 1 150 383 圆柱段长度/mm 700 233 筒毂直径/mm 530 176 筒毂内径/mm 460 153 螺旋叶片外缘直径/mm 930 310 叶片厚度/mm 70 23 圆柱段截线条数/条 11 11 截线距/mm 67 22 轴向倾斜角/(°) 0 0 安装角/(°) 40 40 叶片螺旋升角/(°) 13 13 螺旋叶片头数/个 2 2 每条截线截齿数/个 2 2 尾片与半个齿座距离和/mm 50 17 表 6 煤的物理力学性质指标

真密度/(kg·m-3) 视密度/(kg·m-3) 抗拉强度/MPa 抗压强度/MPa 弹性模量/MPa 坚固性系数 1 332 1 309 1.08 17.71 4 388 2.0 表 7 滚筒装煤仿真结果统计

煤颗粒数/个 装煤率/% 统计区Ⅰ 统计区Ⅱ 原型 5 703 10 038 63.77 模型 290 537 64.93 表 8 载荷数值结果

方向 原型滚筒 模型滚筒 相似预测滚筒载荷均值/N 误差/% 滚筒载荷均值/N 载荷波动系数 滚筒载荷均值/N 载荷波动系数 X 95 247.6 0.026 6 3 589.4 0.027 2 3 527.7 1.75 Y 1 152.1 0.031 4 44.3 0.032 3 42.7 3.74 Z 74 769.5 0.029 5 2 829.5 0.030 6 2 769.2 2.04 -

[1] Van Wyk G, Els D N J, Akdogan G, et al. Discrete element simulation of tribological interactions in rock cutting[J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 65:8-19 doi: 10.1016/j.ijrmms.2013.10.003 [2] Reid A W, McAree P R, Meehan P A, et al. Longwall shearer cutting force estimation[J]. Journal of Dynamic Systems, Measurement, and Control, 2014, 136(3):031008 doi: 10.1115/1.4026326 [3] 司鹄, 王丹丹, 李晓红.高压水射流破岩应力波效应的数值模拟[J].重庆大学学报, 2008, 31(8):942-945 http://d.old.wanfangdata.com.cn/Periodical/cqdxxb200808022Si H, Wang D D, Li X H. Stress wave effect in numerical simulation on rock breaking under high-pressure water jet[J]. Journal of Chongqing University, 2008, 31(8):942-945(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/cqdxxb200808022 [4] 赵丽娟, 何景强, 许军, 等.截齿排列方式对薄煤层采煤机载荷的影响[J].煤炭学报, 2011, 36(8):1401-1406 http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201108033.htmZhao L J, He J Q, Xu J, et al. Effect of pick arrangement on the load of shearer in the thin coal seam[J].Journal of China Coal Society, 2011, 36(8):1401-1406(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201108033.htm [5] 张强, 王海舰, 吴泽光, 等.滚筒式采煤机煤岩截割力学特性及测试系统研究[J].工程设计学报, 2017, 24(4):459-479 doi: 10.3785/j.issn.1006-754X.2017.04.013Zhang Q, Wang H J, Wu Z G, et al. Research of coal-rock cutting mechanical characteristic and test system for drum shearer[J]. Chinese Journal of Engineering Design, 2017, 24(4):459-479(in Chinese) doi: 10.3785/j.issn.1006-754X.2017.04.013 [6] 赵宏梅.基于相似理论的叶片倾斜布置螺旋滚筒装煤性能的研究[J].机械设计与制造, 2009(7):163-165 doi: 10.3969/j.issn.1001-3997.2009.07.066Zhao H M. Research on loading performance of lean vanes based on similarity for spiral drum[J]. Machinery Design & Manufacture, 2009(7):163-165(in Chinese) doi: 10.3969/j.issn.1001-3997.2009.07.066 [7] 彭天好, 王光耀, 张义龙, 等.基于相似理论的采煤机模拟螺旋滚筒的设计[J].工程设计学报, 2016, 23(4):322-326 doi: 10.3785/j.issn.1006-754X.2016.04.004Peng T H, Wang G Y, Zhang Y L, et al. Design of shearer simulated spiral drum based on similarity theory[J]. Journal of Engineering Design, 2016, 23(4):322-326(in Chinese) doi: 10.3785/j.issn.1006-754X.2016.04.004 [8] 麻晓红, 于信伟.基于相似理论的连续采煤机滚筒参数设计[J].黑龙江科技学院学报, 2008, 18(2):111-113 doi: 10.3969/j.issn.1671-0118.2008.02.009Ma X H, Yu X W. Parameter design of continuous miner cutting drum based on similarity theory[J]. Journal of Heilongjiang Institute of Science & Technology, 2008, 18(2):111-113(in Chinese) doi: 10.3969/j.issn.1671-0118.2008.02.009 [9] 王光耀.基于相似理论的采煤机调高试验装置设计研究[D].安徽淮南: 安徽理工大学, 2016 http://cdmd.cnki.com.cn/Article/CDMD-10361-1016178423.htmWang G Y. Design and study of tester for shearer height-adjustment based on similarity theory[D]. Anhui Huainan: Anhui University of Science and Technology, 2016(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10361-1016178423.htm [10] 刘送永.采煤机滚筒截割性能及截割系统动力学研究[D].江苏徐州: 中国矿业大学, 2009Liu S Y. Research on cutting performance of shearer drum and cutting system dynamics[D]. Jiangsu Xuzhou: China University of Mining and Technology, 2009(in Chinese) [11] 任芳.基于多传感器数据融合技术的煤岩界面识别的理论与方法研究[D].太原: 太原理工大学, 2003 http://cdmd.cnki.com.cn/article/cdmd-10112-2004097401.htmRen F. Study on the theory and method of coal-rock interface recognition based on multi-sensor data fusion technique[D]. Taiyuan: Taiyuan University of Technology, 2003(in Chinese) http://cdmd.cnki.com.cn/article/cdmd-10112-2004097401.htm [12] 姜鹏.基于离散元法的碾米机三维仿真分析[D].哈尔滨: 东北农业大学, 2013 http://cdmd.cnki.com.cn/Article/CDMD-10224-1013207070.htmJiang P. Based on the discrete element method of rice mill three-dimensional simulation analysis[D]. Harbin: Northeast Agricultural University, 2013(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10224-1013207070.htm [13] 王国强, 郝万军, 王继新.离散单元法及其在EDEM上的实践[M].西安:西北工业大学出版社, 2010:34-58Wang G Q, Hao W J, Wang J X. Discrete element method and its application in practice on the EDEM[M]. Xi'an:Northwestern Polytechnical University Press, 2010:34-58(in Chinese) [14] 周文君, 卫红波.基于EDEM的带式输送机输送过程仿真及分析[J].煤矿机械, 2013, 34(5):89-91 http://d.old.wanfangdata.com.cn/Periodical/mkjx201305039Zhou W J, Wei H B. Simulation and analysis of belt conveyor based on EDEM software[J]. Coal Mine Machinery, 2013, 34(5):89-91(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/mkjx201305039 [15] 田雨.基于EDEM的滚磨光整加工机理分析和参数优化[D].太原: 太原理工大学, 2014 http://cdmd.cnki.com.cn/Article/CDMD-10112-1014417034.htmTian Y. Mechanism analysis and parameter optimization of barrel finishing based on EDEM[D]. Taiyuan: Taiyuan University of Technology, 2014(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10112-1014417034.htm [16] 毛君, 刘歆妍, 陈洪月, 等.基于EDEM的采煤机滚筒工作性能的仿真研究[J].煤炭学报, 2017, 42(4):1069-1077Mao J, Liu X Y, Chen H Y, et al. Simulation of shearer drum cutting performance based on EDEM[J].Journal of China Coal Society, 2017, 42(4):1069-1077(in Chinese) -

下载:

下载: