Modal Analysis of Mistuned Bladed Disk Assemblies with Film Holes

-

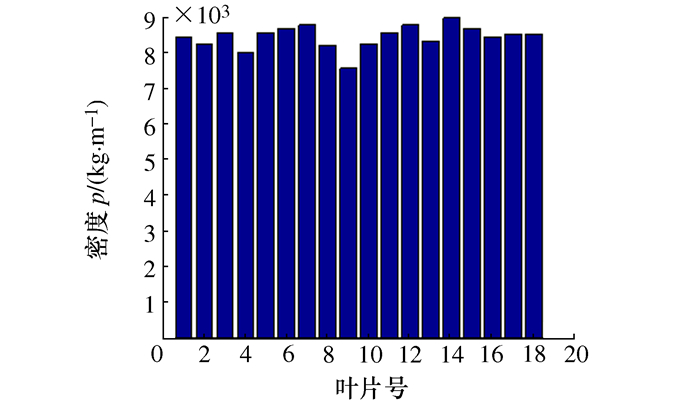

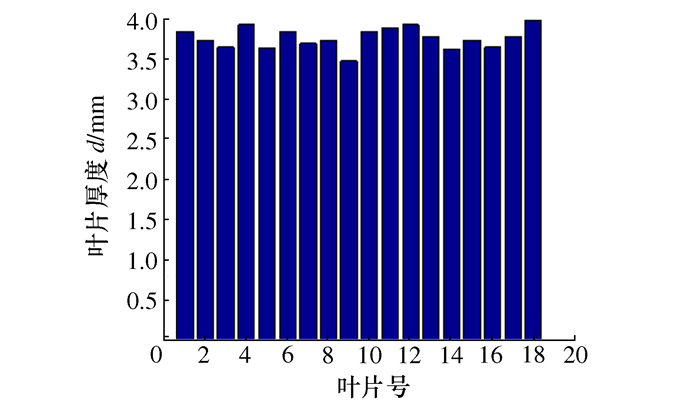

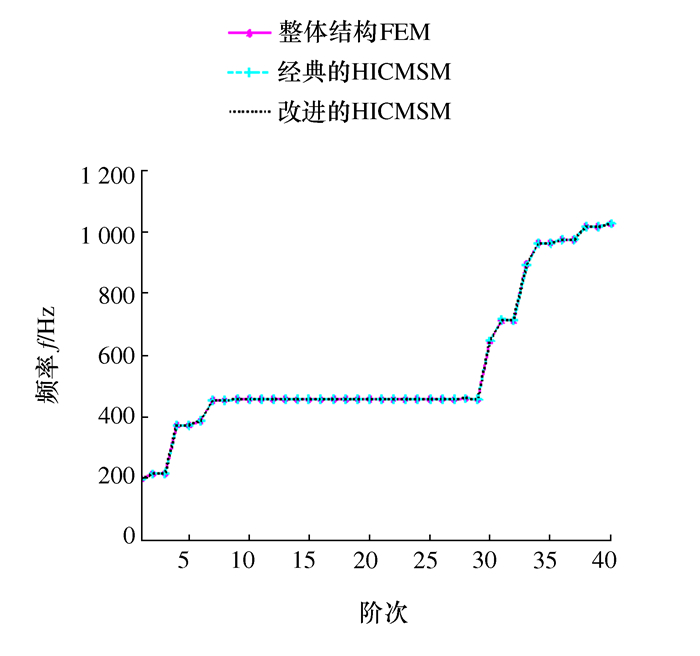

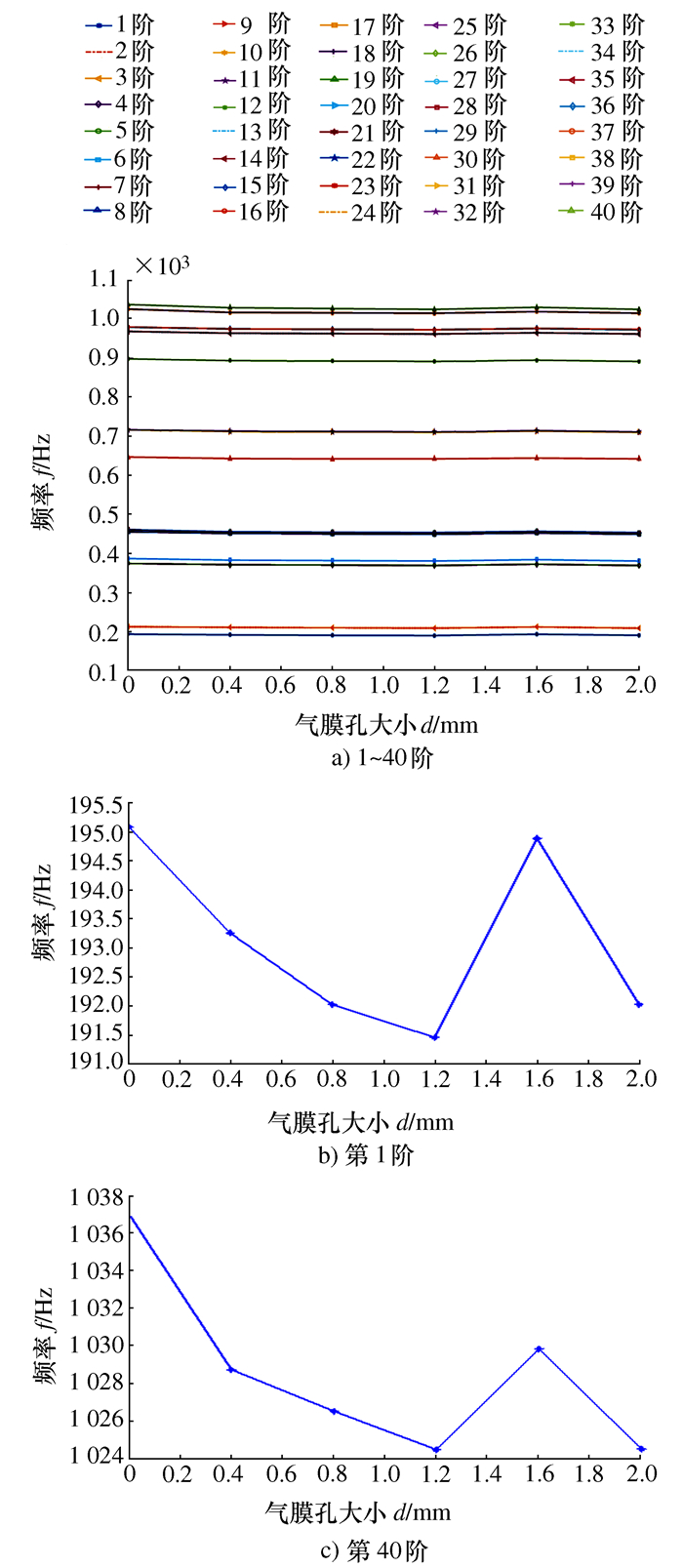

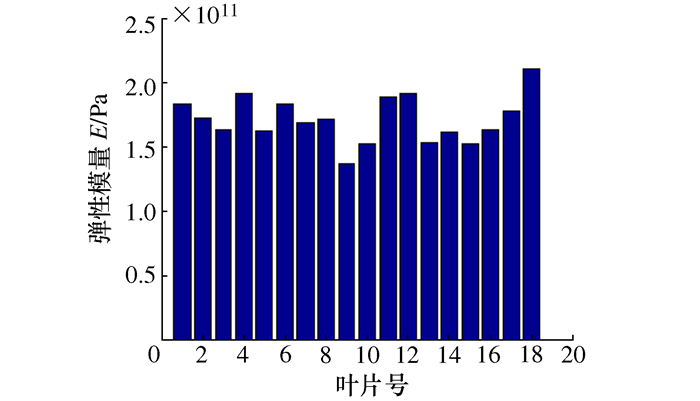

摘要: 在保证精度的条件下,为了提高航空发动机的计算效率与模拟的准确性,对经典混合界面子结构模态综合法(HISCMSM)进行改进,采用改进的HISCMSM建立了带气膜孔的失谐整体叶盘的有限元模型(FEM)并对其进行了模态分析,与高保真有限元模型方法(Finite element model method,FEMM)相比,相对误差≤ 0.79%,比整体高保真FEMM和经典的HICMSM计算效率分别提高31.01%~55.78%,0.89%~5.45%,研究中考虑了气膜孔的影响,发现气膜孔使得叶盘的模态频率降低,其中气膜孔的大小使得模态频率先减小后增大再减小,气膜孔的排列及角度的改变对叶盘模态频率的影响不大,而气膜孔数对其影响较大。为叶盘结构的设计提供了一定指导意义,为下一步的动力响应研究奠定了基础。

-

关键词:

- 改进混合界面子结构模态综合法 /

- 气膜孔 /

- 失谐叶盘 /

- 模态频率

Abstract: Under the guaranteeing the computational accuracy, to ensure the simulation is more in line with the real practical results and increase the calculation efficiency, the classical hybrid interface substructure component modal synthesis method (HISCMSM) is improved. The finite element model (FEM) of the mistuned bladed disk assemblies (MBDA) with film holes is built by this methodology and the modal is analyzed. Comparing with the high fidelity integral structure finite element model method (FEMM), the modal deviation is not more than 0.79%, but the computational time is shortened by 31.01%~55.78%, the computational efficiency is higher by 0.89%~5.45% than that via classical HICMSM. So the computational efficiency and the computational accuracy of this method are both superior to the classical HICMSM. The effect of the film holes on the modal is investigated, comparing with the solid MBDA, the modal is declined. Firstly the modal frequencies decrease after an increase with the increasing of size, and they almost do not alter with the arrangement and the angle changing, but they are impacted by the number of the film holes. The above investigations lay the foundation for the further study on the dynamic response of the MBDA and have a certain guiding significance for the design of the BDA. -

表 1 气膜孔的排布方案

叶片气膜孔 方案 1 2 3 4 5 6 7 8 9 10 11 排列数目 - 8*2 8*2 8*2 8*2 8*2 8*2 8*2 8*4 15*2 15*4 大小/mm - 0.4 0.8 1.2 1.6 2.0 0.8 0.8 0.8 0.8 0.8 角度 - 垂直 垂直 垂直 垂直 垂直 右倾 左倾 垂直 垂直 垂直 表 2 降阶减缩前后叶盘节点数和单元数比较

FEMM 改进的HICMSM 折合率/% 节点数 1 218 072 356 812 71.71 自由度 995 946 128 208 87.13 表 3 不同阶数的计算时间及节省率

阶数 FEMM

t/min经典的HICMSM 改进的HICMSM t/min γ/% t/min γ/% 10 15.8 11.7 25.94 10.9 31.01 20 20.7 15.4 25.61 12.7 38.64 30 35.9 20.3 43.45 18.6 48.18 40 67.4 30.4 54.89 29.8 55.78 -

[1] Martel C, Corral R. Asymptotic description of maximum mistuning amplification of bladed disk forced response[J]. Journal of Engineering for Gas Turbines and Power, 2009, 131(2):022506 doi: 10.1115/1.2968868 [2] Beck J A, Brown J M, Slater J C, et al. Probabilistic mistuning assessment using nominal and geometry based mistuning methods[J]. Journal of Turbomachinery, 2013, 135(3):051004 http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0231033338/ [3] Jung C, Saito A, Epureanu B I. Detection of cracks in mistuned bladed disks using reduced-order models and vibration data[J]. Journal of Vibration and Acoustics, 2012, 134(6):061010 doi: 10.1115/1.4007244 [4] 辛健强, 王建军.失谐流体激励下叶盘结构响应特性[J].航空动力学报, 2012, 27(4):801-810 http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201204014Xin J Q, Wang J J. Forced response characteristic of bladed disk with aerodynamic mistuning[J]. Journal of Aerospace Power, 2012, 27(4):801-810(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201204014 [5] 王艾伦, 孙勃海.随机失谐的成组叶片-轮盘固有振动局部化研究[J].中国机械工程, 2011, 22(7):771-775 http://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201107005.htmWang A L, Sun B H. Analysis of natural vibration localization of random mistuned bladed disk with grouped blades[J]. China Mechanical Engineering, 2011, 22(7):771-775(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201107005.htm [6] Capiez-Lernout E, Soize C, Lombard J P, et al. Blade manufacturing tolerances definition for a mistuned industrial bladed disk[J]. Journal of Engineering for Gas Turbines and Power, 2005, 127(3):621-628 doi: 10.1115/1.1850497 [7] Shanmugam A, Padmanabhan C. A fixed-free interface component mode synthesis method for rotordynamic analysis[J]. Journal of Sound and Vibration, 2006, 297(3-5):664-679 doi: 10.1016/j.jsv.2006.04.011 [8] Bladh R, Student G, Pierre C, et al. Dynamic response predictions for a mistuned industrial turbomachinery rotor using reduced-order modeling[J]. Journal of Engineering for Gas Turbines and Power, 2002, 124(2):311-324 doi: 10.1115/1.1447236 [9] Marinescu O, Epureanu B I, Banu M. Reduced order models of mistuned cracked bladed disks[J]. Journal of Vibration and Acoustics, 2011, 133(5):051014 doi: 10.1115/1.4003940 [10] 崔志琴, 杨瑞峰.复杂机械结构的参数化建模及模态分析[J].机械工程学报, 2008, 44(2):234-237 doi: 10.3321/j.issn:0577-6686.2008.02.040Cui Z Q, Yang R F. Parametric modeling and modal analysis for the complex mechanical structure[J]. Chinese Journal of Mechanical Engineering, 2008, 44(2):234-237(in Chinese) doi: 10.3321/j.issn:0577-6686.2008.02.040 [11] Mao K M, Li B, Wu J, et al. Stiffness influential factors-based dynamic modeling and its parameter identification method of fixed joints in machine tools[J]. International Journal of Machine Tools and Manufacture, 2010, 50(2):156-164 doi: 10.1016/j.ijmachtools.2009.10.017 [12] 杨雯, 杜发荣, 郝勇, 等.宽弦空心风扇叶片动力响应特性研究[J].航空动力学报, 2007, 22(3):444-449 doi: 10.3969/j.issn.1000-8055.2007.03.020Yang W, Du F R, Hao Y, et al. Investigation of dynamic response property of wide-chord hollow fan blade[J]. Journal of Aerospace Power, 2007, 22(3):444-449(in Chinese) doi: 10.3969/j.issn.1000-8055.2007.03.020 [13] 姚玉, 张靖周, 郭文.气膜孔角度对导叶冷却效果影响的数值研究[J].航空动力学报, 2009, 24(3):507-512 http://d.old.wanfangdata.com.cn/Periodical/hkdlxb200903006Yao Y, Zhang J Z, Guo W. Numerical investigation on film cooling effectiveness of stator blade with different angles[J]. Journal of Aerospace Power, 2009, 24(3):507-512(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hkdlxb200903006 [14] Ahn J, Mhetras S, Han J C. Film-cooling effectiveness on a gas turbine blade tip using pressure-sensitive paint[J]. Journal of Heat Transfer, 2005, 127(5):521-530 doi: 10.1115/1.1909208 [15] Kusterer K, Sugimoto T, Tanaka R, et al. Improvement of cooling effectiveness for modern gas turbine blades by optimised positioning of film-cooling holes[J]. VDI Berichte, 2006, 1965:61-72 [16] Rutledge J L, King P I, Rivir R. Time averaged net heat flux reduction for unsteady film cooling[J]. Journal of Engineering for Gas Turbines and Power, 2010, 132(12):121901 doi: 10.1115/1.4001810 [17] Agata Y, Takahashi T, Sakai E, et al. Effects of turbulence promoters of gas turbine blades on film cooling performance[J]. Journal of Thermal Science and Technology, 2012, 7(4):603-618 doi: 10.1299/jtst.7.603 [18] Ai W G, Murray N, Fletcher T H, et al. Deposition near film cooling holes on a high pressure turbine vane[J]. Journal of Turbomachinery, 2012, 134(4):041013 doi: 10.1115/1.4003672 [19] 白斌, 白广忱, 费成巍, 等.改进的混合界面子结构模态综合法在失谐叶盘结构动态特性分析中的应用[J].机械工程学报, 2015, 51(9):73-81 http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201509010Bai B, Bai G C, Fei C W, et al. Application of improved hybrid interface substructural component modal synthesis method in dynamic characteristics analysis of mistuned bladed disk assemblies[J]. Journal of Mechanical Engineering, 2015, 51(9):73-81 http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201509010 -

下载:

下载: