Tooth Surface Root Digging Mechanisms for Numerical Control Power Gear-honing with Internal Teeth Honing Wheel

-

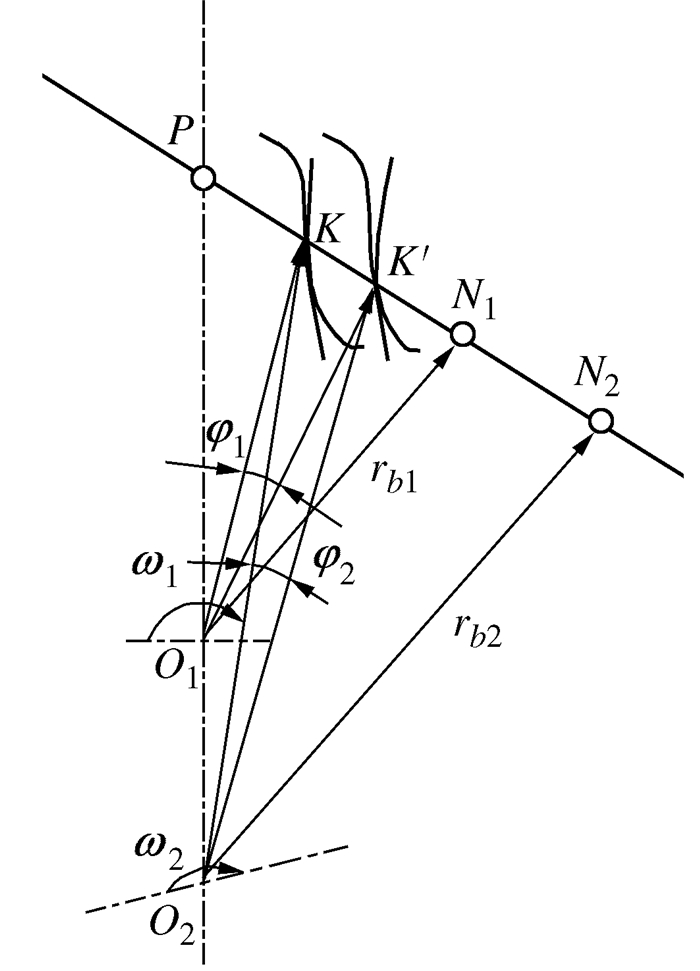

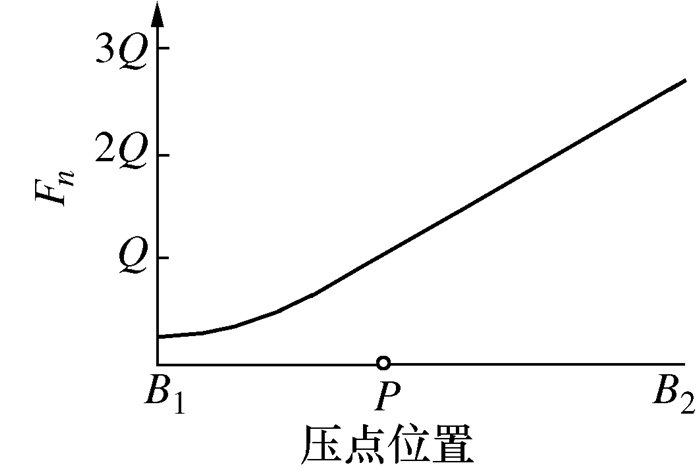

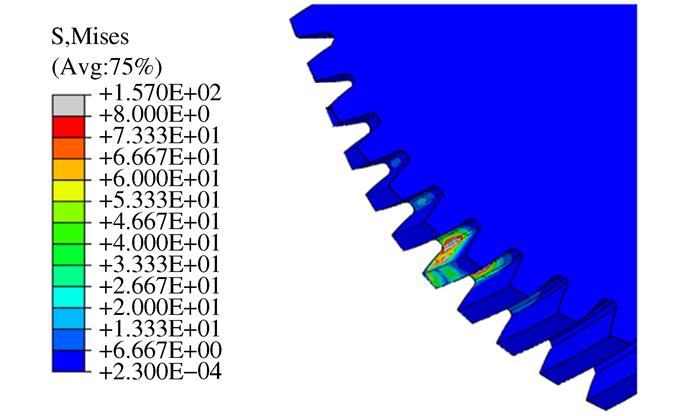

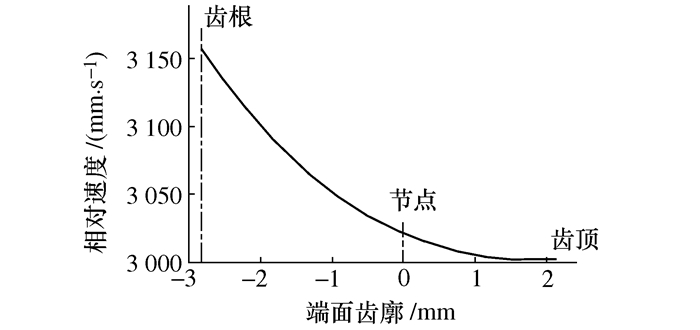

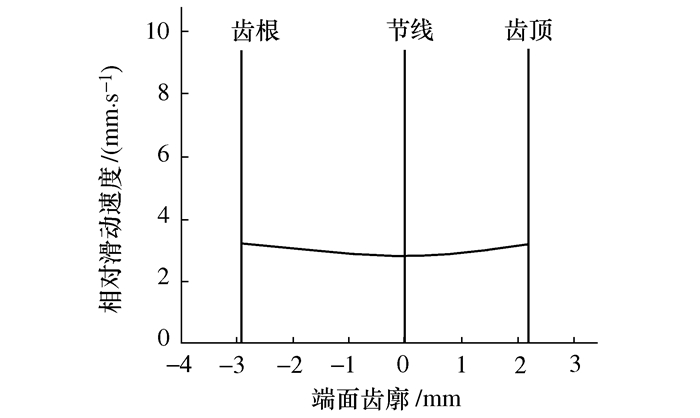

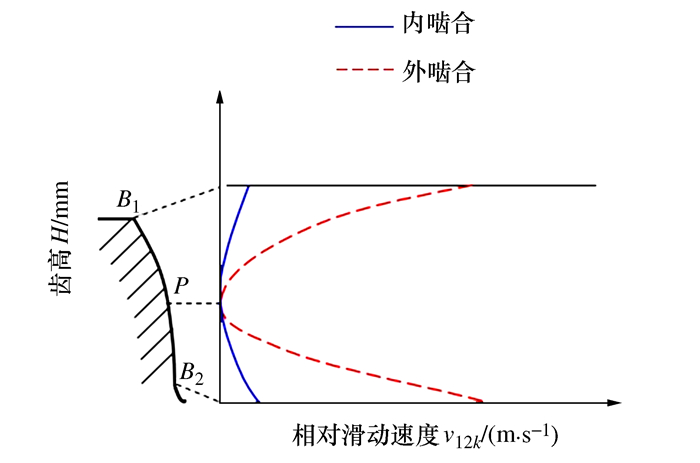

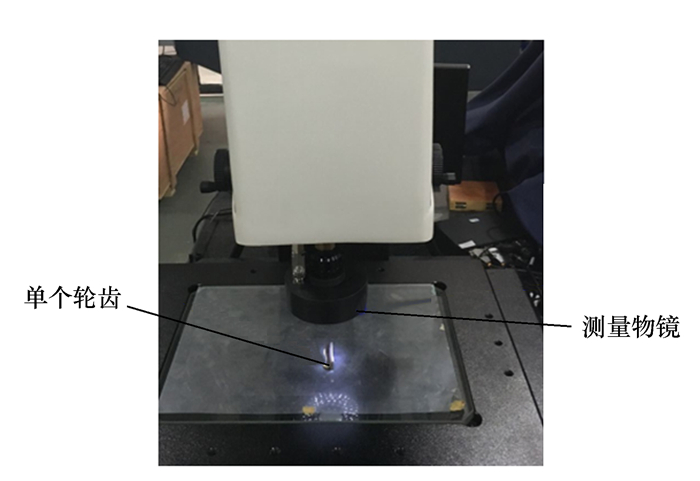

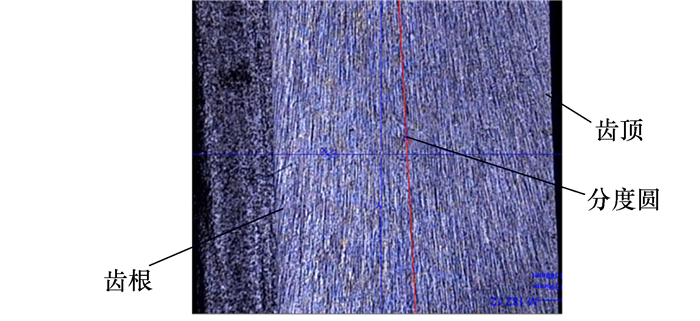

摘要: 为揭示数控内齿珩轮强力珩齿加工后齿面产生挖根现象,基于单颗磨粒切削力模型,建立单颗磨粒切削渐开线齿面力学模型,分析得出齿面珩削压力分布规律,利用三维有限元方法进一步验证其齿根应力最大,指出珩削压力是齿面挖根原因之一。根据内啮合齿面接触方程,分析渐开线齿面的端面齿廓相对速度的变化情况,分析出内齿珩轮强力珩齿加工时,被珩工件齿轮的端面齿廓相对速度变化是齿根处最大,进而造成齿根多珩,洞悉了齿面相对速度也是影响齿面挖根主要因素之一。最后,通过两种方式的强力珩齿实验证明,采用定中心距变压珩齿容易产生齿面挖根现象。Abstract: In order to reveal the phenomenon of root digging on a tooth surface after numerical control power gear-honing with internal teeth honing wheel, the mechanical model of involute tooth surface in single abrasive cutting was built with the cutting force model of a single abrasive particle. The honing pressure distribution on tooth surface was analyzed, using 3D finite element method to further verify the maximum tooth root stress. The analysis results show that honing pressure is one of the causes for tooth surface root digging. According to the contact equation of internal meshing tooth surface and the analysis of the relative velocity of involute tooth profile, the relative velocity variation of the gear profile on the end surface of the honing gear is the largest at the root of the gear and produced by the internal teeth honing wheel with power gear-honing, thus causing the tooth surface root digging of multiple internal teeth honing wheels; the relative velocity of tooth surface is also one of key factors affecting tooth surface root digging. Lastly, experimental results prove in two ways that the power gear-honing and the phenomenon of tooth surface root digging are easily produced with variable pressure gear-honing with center-distance.

-

表 1 内啮合齿轮副的参数

齿轮名称 模数mn/mm 压力角αn/(°) 螺旋角β/(°) 齿数z 齿宽b/mm 外齿轮 2.25 17.5 33 73 27 内齿轮 2.25 17.5 41.722 123 32 -

[1] 郭召.珩齿工艺的技术现状及发展趋势[J].制造技术与机床, 2016(7):51-55 http://d.old.wanfangdata.com.cn/Periodical/zzjsyjc201607018Guo Z. Technology present situation and development trend of gear honing process[J]. Manufacturing Technology & Machine Tool, 2016(7):51-55(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zzjsyjc201607018 [2] Amini N, Westberg H, Klocke F, et al. An experimental study on the effect of power honing on gear surface topography[J]. Gear Technology, 1999, 16(1):11-18 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=95ddc3f27e58bf0d4c3d3ea48022ca80 [3] 韩江, 赵飞虎, 张魁榜, 等.基于Matlab的内齿珩轮齿面建模及珩削特性分析[J].机械传动, 2016, 40(11):140-143, 175 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20162016122200042548Han J, Zhao F H, Zhang K B, et al. Analysis of the tooth surface modeling and honing characteristic of internal gear honing stone based on Matlab[J]. Journal of Mechanical Transmission, 2016, 40(11):140-143, 175(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20162016122200042548 [4] Han J, Zhu Y G, Xia L, et al. A novel gear flank modification methodology on internal gearing power honing gear machine[J]. Mechanism and Machine Theory, 2018, 121:669-682 doi: 10.1016/j.mechmachtheory.2017.11.024 [5] 张满栋.电镀CBN硬珩轮珩齿机理及动态仿真分析[D].太原: 太原理工大学, 2010 http://cdmd.cnki.com.cn/article/cdmd-10112-2010143333.htmZhang M D. The mechanism of gear-honing and dynamic simulation analysis with electroplating CBN hard honing wheel[D]. Taiyuan: Taiyuan University of Technology, 2010(in Chinese) http://cdmd.cnki.com.cn/article/cdmd-10112-2010143333.htm [6] 李云峰, 张满栋.基于LS-DYNA的电镀CBN硬珩齿动态仿真分析[J].图学学报, 2012, 33(4):110-113 doi: 10.3969/j.issn.1003-0158.2012.04.020Li Y F, Zhang M D. Dynamic simulation analysis of plated CBN hard gear-honing processing based on LS-DYNA[J]. Journal of Graphics, 2012, 33(4):110-113(in Chinese) doi: 10.3969/j.issn.1003-0158.2012.04.020 [7] 庄司克雄.磨削加工技术[M].郭隐彪, 王振忠, 译.北京: 机械工业出版社, 2007Syoji K. Grinding technology[M]. Guo Y B, Wang Z Z, trans. Beijing: China Machine Press, 2007(in Chinese) [8] 田培棠, 田凌, 陈志明, 等.圆柱齿轮几何计算原理及实用算法[M].北京:国防工业出版社, 2012Tian P T, Tian L, Chen Z M, et al. Geometric calculation principle and practical algorithm of cylindrical gear[M]. Beijing:National Defense Industry Press, 2012(in Chinese) [9] Litvin F L, Fuentes A. Gear geometry and applied theory[M]. 2nd ed. New York:Cambridge University Press, 2004 -

下载:

下载: